Physically Foamed HIPS Is New Factor in Rigid Packaging

Foam Extrusion

Relief for escalating costs of packaging materials and an opportunity to address sustainability goals are two factors that have helped attract global attention to a new physical foaming technology for HIPS packaging.

Relief for escalating costs of packaging materials and an opportunity to address sustainability goals are two factors that have helped attract global attention to a new physical foaming technology for HIPS packaging. First introduced at the K 2010 show in Germany last fall, this liquid-CO2 foaming technology suitable for existing single-screw extrusion lines first came to commercialization at an Australian customer within the past month.

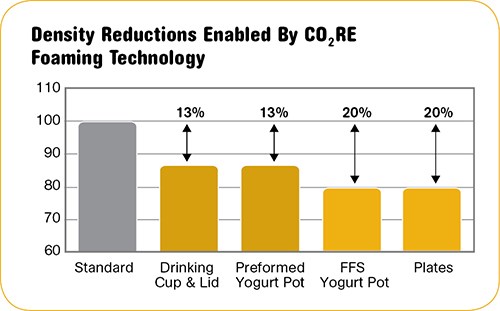

Dubbed CO2RE (pronounced “core”) Foaming Technology, this patented technique comes from Styron LLC, whose U.S. offices are in Midland, Mich. (Styron plans to change its name to Trinseo and recently moved its global operating center to Berwin, Pa.) It produces HIPS sheet with a foamed core and solid surface, suitable for deep-draw thermoforming into rigid packaging with walls as thin as 0.3 to 1.5 mm (0.01 to 0.06 in.). Overall density reductions can be 13% to 20%, though one licensee has achieved 24%. Thus, it does not compete with much lower-density PS foam sheet used in meat trays and clamshell packs, which is produced on specialized tandem extrusion lines with annular dies. By contrast, CO2RE foaming technology can be used on existing conventional single-screw sheet extrusion lines with flat dies at a modest conversion cost, Styron says. Liquid CO2 reportedly offers cost and performance advantages over chemical blowing agents. Initial targets for the technology are dairy packaging and disposable foodservice items like plates and cups.

GLOBAL INTEREST

According to John Case, Styron’s global marketing manager for packaging and consumer goods, CO2RE technology has attracted considerable interest over the past year in Europe, Asia/Pacific, South Africa, and Latin America. “We have lots of orders for samples and many customers are in various stages of process validation,” says Case. The company (styron.com) is currently assessing plans for introducing CO2RE in North America.

The first CO2RE licensee to bring actual products to market is REMA Industries in Australia. It introduced the technology with its Biorene foodservice products that contain an organic additive to make them biodegradable. REMA reportedly will implement CO2RE foaming technology to convert all its products from solid to foamed HIPS.

Another licensee, Intraplas in Portugal, is in the final stages of commissioning its first CO2RE line for form/fill/seal dairy packaging. Other packaging firms who made testimonials about the potential added value of CO2RE foaming technology on Styron’s website are Promens in Sweden and Fernholz in Germany, along with packaging distributor Toyota Tsusho of Japan.

Styron works with customers to validate the CO2RE process for specific applications at a demonstration facility in Terneuzen, The Netherlands. Styron describes the necessary equipment modifications as low cost—meaning 2 to 8 Euros per metric ton of annual output, depending on extruder size, as compared with material cost savings of 250 to 400 Euros/m.t.

Hardware modifications include a new screw, designed by Styron to provide good mixing of the CO2 with the PS melt. The blowing agent can be introduced through a vent port in the barrel. Additional extras are the liquid-CO2 storage and pumping system. Very little additional floorspace is required, Case notes. Styron reports that addition of liquid CO2 to the melt can enable higher output if the downstream system can handle it.

Foaming does produce some texture on the surface of products, but Case says this is perceived as an advantage by some customers. Alternatives to achieve a glossy surface are sleeve or in-mold labeling or coextrusion with a solid PS cap layer.

Related Content

How Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreCooling the Feed Throat and Screw: How Much Water Do You Need?

It’s one of the biggest quandaries in extrusion, as there is little or nothing published to give operators some guidance. So let’s try to shed some light on this trial-and-error process.

Read MoreFormulating LLDPE/LDPE Blends For Abuse–Resistant Blown Film

A new study shows how the type and amount of LDPE in blends with LLDPE affect the processing and strength/toughness properties of blown film. Data are shown for both LDPE-rich and LLDPE-rich blends.

Read MoreFully Automated Extrusion Process Enables Use of Composites for Manufacturing Pressure Tanks

Amtrol was looking for a more cost-effective means to produce thin-wall liners for a new line of pressure tanks. With the help of a team of suppliers, they built one of the world’s most sophisticated extrusion lines.

Read MoreRead Next

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read More