Smarter & More Collaborative: Yushin Taps into Two Major Robot Trends

New Yushin robots have Industry 4.0 features and collaborative capability.

How smart can a robot be? Several answers to that question are apparent at Booth W2173, where Yushin America is putting several linear robots—and some special non-linear ones—through their paces in automated cells. Chris Parrillo, national sales manager, sees robots as part of the Industry 4.0 trend to connectivity and self-regulation. For example, Yushin’s newest and most sophisticated servo robots, the FRA series, has a new E-touch V controller that permits remote troubleshooting and predictive maintenance.

Also new is the Intu Line, a cloud-based service for reporting production statistics for the molding cell via the robot control. Such data include production counts, uptime ratio, cycle times, error counts, stoppage logs, and live images of the process taken every cycle by a camera built into the kick beam. Several FRA robots in various booths at NPE communicate their data to the cloud, where it will be displayed in the Yushin booth on smartphones and tablets. This data can also be shared with Yushin’s service personnel to quickly diagnose problems and get production back on line.

Parrillo points out that FRA robots also come with Active Vibration Control to minimize “shake” and allow faster takeout by sensing its own vibrations and counteracting them instantaneously; Arc Motion Control, which blends linear movements on multiple axes simultaneously into a smooth curve that shortens the overall path. “At the booth, we are showing how it can shave 9% to 35% off the overall cycle time,” Parrillo states.

A third “smart” function is Adaptive Motion Control, which optimizes acceleration and deceleration to minimize vibration. As Parrillo explains it, the robot automatically adjusts speeds to move faster when its axes are tucked in close to the robot body and adjusts servo speeds when the robot is working at the extremities of their axes during portions of the cycle such as part removal, insert placement, degating, or part placement.

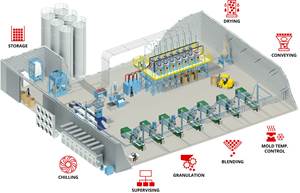

While a number of exhibitors at NPE will show robots being controlled from the injection machine, Yushin is showing the capability of its robots to not only communicate with the press, but to act as cell managers for all post-mold activities beside the machine. Explains Parrillo, “FRA robots are equipped with protocols such as DeviceNet, EtherCAT, and EtherNet/IP, allowing simple integration with downstream equipment for conveying, assembly, decorating, visual inspection, and packaging.”

Yushin’s most elaborate cell utilizes three robots and two injection machines to mold and assemble a sports protein-drink cup and lid with in-mold labeling and post-mold pad printing. What’s more, unscrewing of both threaded parts from the mold is accomplished by the robots’ custom end-of-arm tooling with rotating servo nests—much simpler and less costly than a bulky rack-and-pinion unscrewing device on the mold.

The finished sports-drink container will be available for visitors to take home. After being assembled and decorated, the cup will be placed on a conveyor by a brand-new addition to Yushin’s robot stable—the OB-7 collaborative robot, built by Productive Robotics in California. This seven-axis device is said to operate safely around people in some applications, reducing the need for hard safety guarding. It has a mobile base so it can be moved easily between machines. And it requires no expertise for complex programming, using the simple lead-through teach method. It even has a built-in camera to read QR codes at each job station to automatically load the job recipe. A future software upgrade, says Parrillo, will enable the robot to “see” and track randomly placed parts on a conveyor.

“Collaborative robots definitely have a place,” says Parrillo. “Customers are constantly complaining that they can’t find operators to perform minor tasks, especially for short runs. These robots are perfect for basic pick-and-place jobs like case packing or tray loading.”

Related Content

Drones and Injection Molding Ready for Takeoff

Drones and unmanned aerial vehicles (UAV) are approaching an inflection point where their production volumes — and functionality — will increasingly point to injection molding.

Read MoreA Cost Saving Modular Approach to Resin Drying Automation

Whether implementing a moisture-sensing closed-loop system for a single dryer, or automating an entire plant, technology is available to take the guesswork and worry out of resin drying. Using a modular approach allows processors to start simple and build more capabilities over time.

Read MoreSystem Offers 'Lights Out' Mold-Channel Cleaning & Diagnostics

New system automatically cleans mold-cooling lines—including conformal channels—removing rust and calcium, among other deposits, while simultaneously testing for leaks, measuring flow rate and applying rust inhibitor.

Read MoreCobot Creates 'Cell Manufacturing Dream' for Thermoformer

Kal Plastics deploys Universal Robot trimming cobot for a fraction of the cost and lead time of a CNC machine, cuts trimming time nearly in half and reduces late shipments to under 1% — all while improving employee safety and growth opportunities.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreRecycling Partners Collaborate to Eliminate Production Scrap Waste at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair will seek to recover and recycle 100% of the parts produced at the show.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE 2024.

Read More