U.S. Plastic Bottle Recycling Reaches 3 Billion Pounds

Single-stream collection of household recyclables continues to grow, resulting in higher participation rates.

Plastic bottle recycling grew 97 million pounds in 2014 to top 3 billion pounds for the year, according to figures released jointly by the Association of Plastic Recyclers (APR) and the American Chemistry Council (ACC). The recycling rate for plastic bottles climbed 1% to 31.8% for the year.

Trends in plastics recycling highlighted in the 25th annual National Post-Consumer Plastics Bottle Recycling Report include:

- Single-stream collection of household recyclables continues to grow, resulting in higher participation rates

- Use of plastic bottles in packaging applications is expanding but offset by continued lightweighting and increased use of concentrates with smaller, lighter bottles

- Lack of access to away-from-home recycling continues to be a barrier to increased collection

During 2014, the collection of high-density polyethylene (HDPE) bottles—a category that includes milk jugs and bottles for household cleaners and detergents—rose to nearly 1.1 billion pounds, a gain of over 62 million pounds from 2013. The recycling rate for HDPE bottles rose to 33.6%.

A higher percentage of all post-consumer plastic bottle material was processed by domestic reclaimers in 2014. Exports of all post-consumer plastic bottles rose slightly (in pounds) but fell to the lowest percentage of exports in six years (21.9%) as the amount of bottles collected increased faster than did exports, according to the report. The drop in exports may reflect the strength of the U.S. dollar and growth in domestic reclamation capacity.

U.S. reclamation capacity for HDPE increased to its highest level ever in 2014. Exports of HDPE bottles rose from 15.6 to 19.7% (218 million pounds) of domestically collected material, and domestic reclaimers processed approximately 951 million pounds of HDPE bottles in 2014.

“The message to American consumers is that plastic bottles are valuable resources even after they’ve been used,” said Steve Alexander, executive director of APR. “Americans generated an estimated $730 million in recycled plastic bottles in 2014. The simple act of recycling helps generate local revenue, supports recycling jobs, and enables us to continue to benefit from these useful resources.”

“This report clearly illustrates 25 years of year-over-year growth in recycling plastic bottles,” added Steve Russell, vice president of plastics for the American Chemistry Council. “Plastics help reduce energy use and conserve resources—and after use, these efficient products and packages are increasingly valued as recycled materials. We’re confident that plastics recycling will continue to grow, and we will continue working to accelerate that growth.”

This year’s survey also found that the collection of polypropylene (PP) bottles jumped 28.3% for the year to reach 79.5 million pounds, as the collection rate sprang to 44.9%. Domestic processing of postconsumer PP bottles grew to 65.3 million pounds. PP bottles deliberately recycled as PP (instead of blended with HDPE) rose from 44.2 million pounds in 2013 to 45.6 million pounds in 2014. Although PP caps, closures and non-bottle containers are widely collected for recycling in the United States, these data are presented in a separate report on recycling non-bottle rigid plastics, which will be released in the coming months.

Together, polyethylene terephthalate (PET) and HDPE bottles continue to make up nearly 97% of the U.S. market for plastic bottles with PP comprising 1.9%, LDPE 0.8% and PVC 0.4%.

Related Content

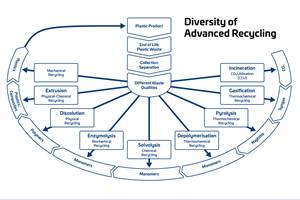

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

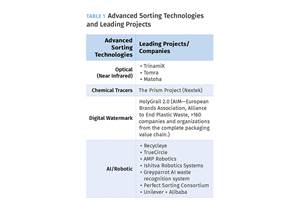

Read MoreRecycling: What's Ahead in Advanced Sorting Technology

As the industry tries to ramp up recycling, there are several innovative sorting solutions in the offing—ranging from enhanced optical sorting technologies and chemical tracers to advanced solutions based digital watermarks and artificial intelligence.

Read MoreReversing Logistics for Plastic Film Recycling

Learn how Mainetti built a circular supply chain for clear film packaging.

Read MoreNew Facility Refreshes Post-Consumer PP by Washing Out Additives, Contaminants

PureCycle prepares to scale up its novel solvent recycling approach as new facility nears completion.

Read MoreRead Next

Processor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More