First Thermoplastic Composite Gearbox Housing: 30% Lighter Than Aluminum

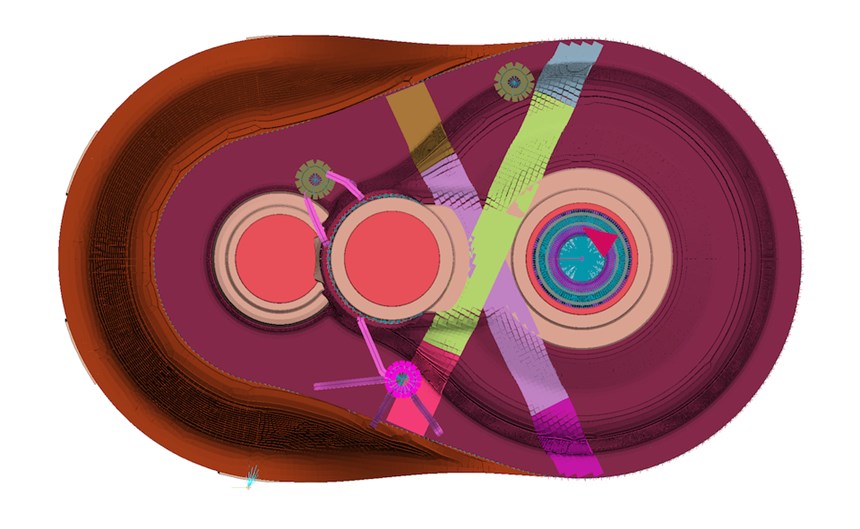

ARRK’s lightweight injection molded construction is made with layer-optimized organic sheeting.

I recently had the pleasure of interacting with the ARRK Engineering Division of Germany’s ARRK Group regarding what they claim to be the first thermoplastic composite gearbox housing with layer-optimized organic sheeting.

Geared to electric vehicles in particular, as keeping weight down is paramount in ensuring long range, this prototype was developed by an interdisciplinary team focused around Münich-based Technology & Innovation at ARRK Engineering.

This injection-molded structure is made of short glass-fiber-reinforced nylon, and the organo-sheet is a carbon fiber with a nylon matrix. It boasts a 30% lower weight than a conventional aluminum model. According to ARRK sources, until they developed this fully functional thermoplastic composite gearbox, the potential for the optimization offered in this area had only been highlighted through various technology demonstrations.

The minimal investment costs and the use of tried-and-tested technologies make long-fiber-reinforced components with thermoplastic matrices very attractive from a cost perspective.

“We were drawn to the project due its mix of complex nature and feasibility,” explained Monika Kreutzmann, head of the Center of Competence (CoC) Composite at ARRK. Those involved aspired to match the profitability of the conventionally used materials, at a sufficient order quantity. According to ARRK’s head of technology and innovation Thomas Schneider, the minimal investment costs and the use of tried-and-tested technologies make long-fiber-reinforced components with thermoplastic matrices very attractive from a cost perspective.

Re-engineering Achieves Target Values for Composite Housing

There were three phases to this project: the rough concept was set out in the first; the second dealt with the final draft; and the third phase looked at the fine details. The target values, which at the minimum had to be met, were first calculated by re-engineering an existing aluminum housing. Since rigidity in particular has a significant effect on the performance of the gearbox, geometry was given a lot of thought here. The development was driven forward with a heavy reliance on simulation methods, which were used for testing all approaches and trialing solution concepts in a virtual environment as to their functionality and potential.

According to Kreutzmann, the short cycle times and high quantities involved led the team to opt for the thermoplastic material—a nylon, which was to be extrusion-coated using short-fiber-reinforced plastic. The various scenarios and their feasibility were each evaluated and optimized in pressure casting and injection molding simulations.

Topology Optimization: UD tapes provide localized reinforcement

To design the installation space, the team had to first determine the force profiles in the housing on the back of an optimized topology—taking the traction and tension areas into account. The resulting concept served as an indicator of where the material was to be positioned and how the layers of the organic sheeting had to be optimized in order to achieve the required rigidity. Furthermore, the deformations that could potentially arise when placed under load were examined in extensive simulations, allowing the torsion of the housing to be derived as a dimensional variable, which was countered with 45º layers.

“In addition to FEM optimization, we also manually sought out specific strengthening methods, which involved as little additional weight as possible,” explained engineering co-project dealer Raik Rademacher. Crossed unidirectional (UD) tapes proved to have a particularly positive impact here: the thickness of the actual organic sheets was subsequently able to be reduced from 5mm to 4 mm, not only saving weight but also facilitating the sheet’s remodeling process.

The detailed draft still included the use of aluminum inserts, which transmit the loads discharged into the bearing onto the organic sheeting. These inserts allowed shaft tilt to be significantly reduced. Alongside the UD tapes, injection molding ribs on the organic sheeting were used to ensure rigidity targets were achieved. A positive side effect of the injection molding is that it can be implemented on the final contour and it requires no additional drilling, meaning reduced secondary operations. Short glass fiber-reinforced injection also prevents contact between the carbon fiber and the metallic inserts: this galvanic isolation prevents the emergence of corrosion, meaning no additional coating is required.

The Production Process—from the preform to the finished component

Manufacturability was ensured by the team via the close involvement of Shapers—the tool manufacturing specialists within the AARK Group, and through simulations of the pressing process using the software of cooperative partner ESI. As the prototypes for the first half of the housing were created in a two-step proess, the new development served as a tool for the pressing process and was also required for the subsequent injection.

In the first phase, the organic sheeting and reinforcing UD tapes are heated and reformed in a pressing process in such a way that the matrix materials are combined and the desired preform is created. The preform is then cut to size using water jet cutting. In the second phase, the preform is heated again and back molded within the injection molding tool, creating the final geometry including the ribs and other functional surfaces.

Mechanical Performance Tests to Come

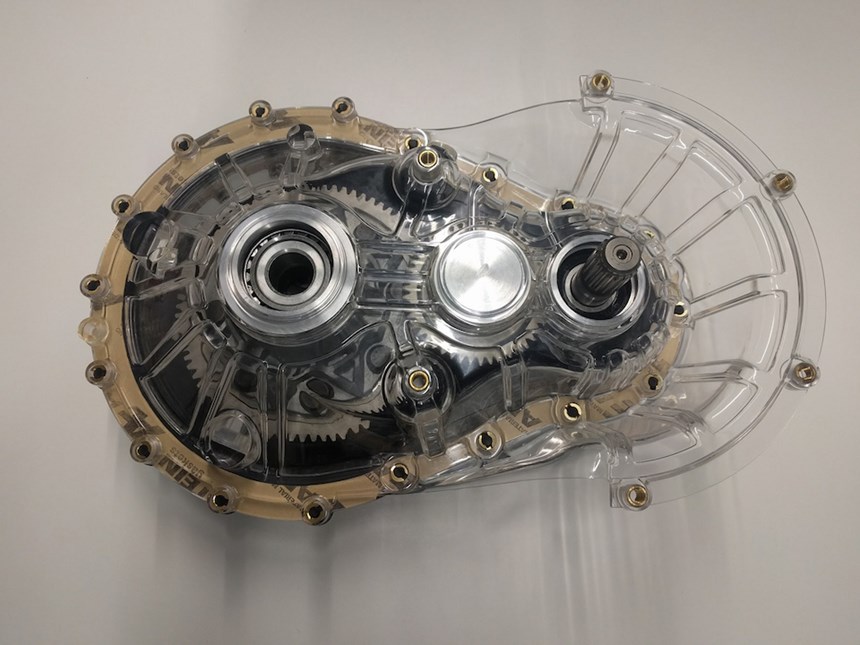

The weight reduction was as hoped: the gearbox housing was made up to 30% lighter through the use of fiber-reinforced nylon. The prototype is to be subjected to comprehensive hardware tests later this year for functional control purposes while, at the same time, the second half of the housing is to be created. A transparent PMMA plastic prototype has already been implemented to better illustrate the technology. The assembled version was unveiled to th public for the very first time as part of the Composites Europe even in December 2016.

“The excited interest from a wide range of industries is a testament to the development’s potential. We believe the cost effectiveness of this process will increase as the use of its automation potential rises. If, for example, the two process steps could be combined, the production costs would sink significantly,” predicted Kreutzmann.

Related Content

Celanese to ‘Shine’ at CES 2023 with Expanded Portfolio of Materials

With it acquisition of DuPont’s engineering resins, Celanese’s resin solutions for automotive electrification, e-mobility and consumer electronics are plentiful.

Read MoreInjection Molded Tape and Resin “Sandwich” Technology Debuts

During its Mobility Days in Austria, Engel and KTM Technologies debuted an all-plastic molded motorcycle seat base produced via a tape-sandwich process that can run in a standard molding process.

Read MoreAtop the Plastics Pyramid

Allegheny Performance Plastics specializes in molding parts from high-temperature resins for demanding applications as part of its mission to take on jobs ‘no one else does.’

Read MoreImpacts of Auto’s Switch to Sustainability

Of all the trends you'll see at NPE2024, this one is BIG. Not only is the auto industry transitioning to electrification but there are concerted efforts to modify the materials used, especially polymers, for interior applications.

Read MoreRead Next

Troubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More