Demand for Consumer Products Gradually Improving

Wood On Plastics

The market for U.S.-made consumer products is steadily improving, just not at a very rapid rate. Our forecast calls for this trend to continue through the end of this year, with annual growth for 2012 coming in at just under 2%.

Through the first half of 2012, the prevailing trend in monthly U.S. output of consumer products was steady but unspectacular growth. Compared with the data from the first two quarters of 2011, production of these products has expanded by 1.6% so far this year. The rate of growth for all of 2011 was 1.4%.

So at present, the market for U.S.-made consumer products is steadily improving, just not at a very rapid rate. Our forecast calls for this trend to continue through the end of this year, with annual growth for 2012 coming in at just under 2%. We expect growth to accelerate to just over 3% in 2013.

This theme of slow growth should sound familiar because the same is happening in the overall U.S. economy. Total GDP grew by less than 2% in the first half of 2012, and it is not expected to perform much better until 2013. And just to be clear, the data we are examining this month does not include products such as motor vehicles and parts, energy products, or anything considered “high-tech.” What we are looking at here are your everyday household items that are typically produced in large quantity and are relatively inexpensive.

Although the recent changes in overall market activity have been muted, there are at least three factors that will have significant effects in the future on the processors who manufacture plastic consumer products. These are:

1. The pending recovery in residential construction and real estate. These sectors suffered severe damage when the housing bubble burst in 2008, and it will take them about another year before confidence is sufficiently restored. Five years is a long time to wait for a rebound, but they will recover; and when they do it will generate a strong boost in demand for many types of plastic consumer products.

2. The rising costs of resins and other materials. The price of plastics resins is closely tied to the price of crude oil. In the future, the price of resins in the U.S. will likely be based on the price of natural gas, but since I cannot predict with any certainty when this transition will occur, we have to expect that resin prices will continue to follow the market for crude oil for the foreseeable future. As the global economy recovers, the price of oil, resins, steel, and most other commodities used in the manufacture of consumer products will most likely rise. It is also likely that the price of everything will else rise (this is also known as inflation), so manufacturers may be able to pass some of these costs on to their customers, but then again, maybe not. Suffice to say that the pressures stemming from pricing strategy and cost management will intensify.

3. Less severe competition from low-cost countries. The inherent advantages that arise from manufacturing close to the marketplace cannot be ignored forever. As the market conditions change, and once all of the costs associated with getting a product to market are more accurately counted, the advantages of manufacturing overseas (especially in China) will rapidly diminish for many types of products. Offshoring was trendy for a while, but a lot of that work (and most of the dollars that are currently stored in Chinese vaults) will be repatriated sooner or later. Trends are cyclical, so nothing lasts forever.

WHAT THIS MEANS TO YOU

•Consumers, manufacturers, and policymakers continue to struggle with the concepts of sustainable, recyclable, environmentally sound, etc. But it would be a mistake to think that these things will go away. There are huge opportunities here.

•For molders and extruders of consumer products, the battle will increasingly focus on materials. Materials prices, market acceptance or de-selection, regulations, and performance will play a huge role in how products are designed and marketed.

•These changes will be driven by social media and increased access to the internet

Related Content

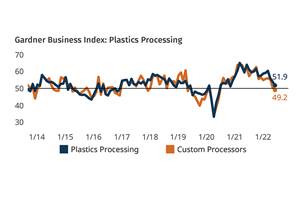

Processing Slips as Summer Simmers

Monthly index suggests slower growth in June for plastics processors overall and contraction for custom firms.

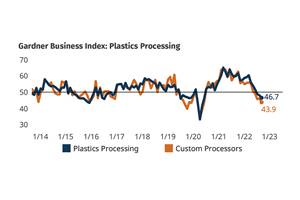

Read MorePlastics Processing Continues to Contract

The September Index signaled a second month of declining activity for plastics processors overall, while custom processors fared even worse.

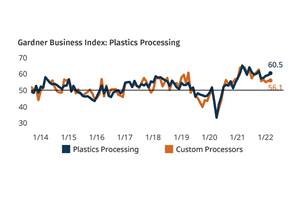

Read MorePlastics Processing Growth Slows Slightly

May reading for plastics processors is, for the most part, a continuation of what we saw in April.

Read MoreRead Next

Why (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More

.png;maxWidth=970;quality=90)