You must keep drying systems in good working order to pre-condition your material satisfactorily for processing. Here’s an overview of the critical, and often overlooked elements of the drying process that can help you get the most out of your drying equipment and material investment:

- Process and Regeneration Heaters

- Air Flow Components

- Filters and Blowers

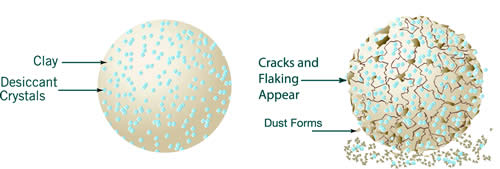

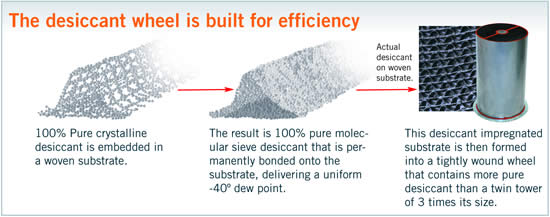

- Moisture Absorbing Desiccant

Heater Maintenance in Plastics Processing

Maintaining Process Heaters

The process heater elements in a dryer are a critical part of the dehumidification process because they elevate the material temperature to purge moisture from the resin.

Monitor process heaters closely to ensure they are:

- Reaching the desired temperature promptly

- Properly switching on and off in response to the temperature controller’s signals

Slowness, or inability to attain the temperature set on the controller, is a sign of a burned out or failing heater element.

When your process heater slows down:

- The dryer should be taken out of service

- The heaters should be replaced

It is best to replace all heaters within a multiple-element heater box at the same time, since the expected life of each element is approximately the same.

Maintaining Regeneration Heaters

There is a second set of heaters in an electric dual bed, desiccant wheel or carousel drying system. It is for the drying or regenerating of the desiccant. The manufacturer usually sets the temperature on a hidden temperature controller. The regeneration heater plays an important role in the operation of the dryer, keeping the desiccant dried out, so it can efficiently remove the moisture from the process air stream.

How to Monitor Regeneration Heaters:

- Observe controller lights thermometers or amp meters if supplied by manufacturer

- Observe heater contactors

- Measure heat output

- Compare temperature reading to values specified in dryer instruction manual for that dryer model that type of desiccant