Graphene-Enhanced Stretch Film Billed as 'World First'

Thinner, stronger films to be commercialized by Brazil’s Packseven in August.

Packseven, one of Brazil's largest flexible film processors, has commercialized what’s been billed as the world's first graphene-enhanced stretch film. The new ultra-thin film, developed using Gerdau Graphene's specialized graphene additive technology, is reportedly significantly thinner and more durable: initial testing revealed that the new films could pack 120% more material without breaking compared with comparable flexible films. More durable stretch films reduce consumption of the material per pallet and increase safety in packing and loading, says the additive supplier. The film is expected to be made available for sale before October.

“Integrating graphene into our stretch film enhances its known properties, such as increasing its resistance to sharp objects that could pierce it. On top of that, it's more efficient — you use less of it when stretching, which means a big jump in cargo safety,” says Kléber Ávila, CEO of Packseven. “Our goal is to provide a more durable film to the market and we think this will set a new bar for quality, delivering numerous benefits to transportation, storage, and all sorts of packaging needs.”

Photo: Gerdau Graphene

The film is seven layers and is produced by Packseven in thicknesses ranging from 17µm to 35µm. The companies say the addition of graphene has no impact on recyclability; it is as recyclable as the polymer matrix into which it is added.

Thinner Films

“The addition of graphene to PE films has shown gains in material resistance, making it possible to significantly reduce the thickness of the film,” notes Flavia Zangrandi, head of product development at Gerdau Graphene. “The addition of graphene thus allows for a performance gain combined with a more sustainable material due to the reduction of virgin plastic and/or the increase of recycled plastic in the composition of the final product. Gerdau Graphene's mission is to harness the power of graphene for industrial applications and our partnership with Packseven will deliver the next-generation of high-performance, low-weight films to the market.”

Gerdau Graphene recently announced the commercial availability of its Poly-G polyethylene masterbatch, a graphene-enhanced additive for plastic resins suitable for the production of films, profiles, and sheets formed through the extrusion processes. The new thermoplastic products created using Poly-G are proven to be stronger and offer greater overall performance while costing less to manufacture and producing significantly less waste across the value chain.

“Packseven will deliver the next-generation of high-performance, low-weight films to the market.”

Poly-G was piloted in a series of industrial applications within Gerdau's factories before commercialization, including as a film for construction nail packaging. Gerdau found that by using the new, 25% thinner graphene-enhanced film, far fewer nails perforated the packaging. As a result, Gerdau reported a 39% reduction in the volume of discarded damaged packaging and a 7% increase in film productivity.

Graphene, considered the strongest material on Earth, is composed of an atomic monolayer of carbon atoms arranged hexagonally in a honeycomb-like structure. Since it was isolated in 2004, graphene's extraordinary chemical, physical, electrical, thermal, and mechanical properties have captivated the world and led to its inventors winning the Nobel Prize in Physics.

Graphene can be blended with plastics, lending its strength to the polymer matrix, and making the blended material much stronger. In addition to improving physical and mechanical properties, graphene also increases barrier properties against liquids and gasses; protection against weather, oxidation, and UV light; and increased electrical and thermal conductivity.

Related Content

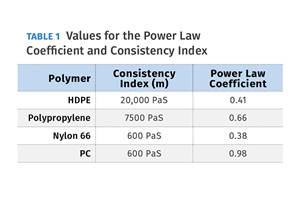

The Importance of Viscosity in Melting

The calculations required to determine the right melt temperature for each polymer are complicated. Knowing the power-law coefficient and the consistency index of the polymer you run might prove useful.

Read MoreAvoid Four Common Traps In Granulation

Today, more than ever, granulation is an important step in the total production process. Our expert explains a few of the many common traps to avoid when thinking about granulators

Read MoreHow Much L/D Do You Really Need?

Just like selecting the extruder size and drive combination, the L/D should be carefully evaluated.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreRead Next

Troubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More