New Package Concept Offers Relief from PP Shortages & Soaring Prices

A new IML approach that uses a thick paper label as most of the structure of a plastic container can slash resin use drastically—especially handy when resin supplies are tight and prices are soaring.

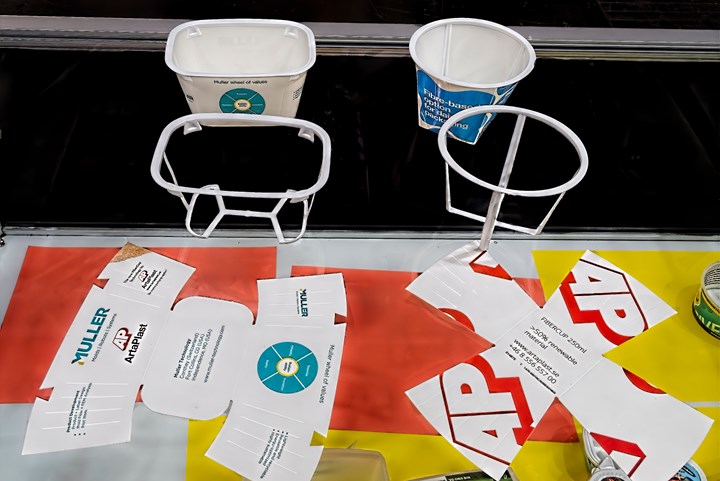

With Gulf Coast chemicals and plastics production disrupted by winter storms, resulting in tight availability and galloping price increases for PP and other resins, this might be a perfect time to consider a new injection molded package concept that can reduce plastic usage by up to 76%. As reported in Feb. ’20 Starting Up, the concept was introduced publicly at the K 2019 fair in Düsseldorf by Swiss-based Muller Group, specialists in molds and automation for thin-wall packaging and in-mold labeling (IML). Working with Artaplast of Sweden, Muller developed mold and IML automation technology for replacing up to 76% of the PP in a dairy cup with a thin skeleton injection molded over a thick paper IML label coated on both sides with PP. Artaplast calls the concept Fiber Cup and has applied it to cottage cheese and yogurt containers in Europe.

Muller Technology offers tooling and automation for an IML concept in which a thick coated-paper label reduces the plastic content to a mere skeleton.

Taras Konowal, director of sales and marketing for Muller Technology Colorado (formerly CBW Automation), tells Plastics Technology that more applications are emerging—including dairy containers up to 1 gal—and interest is starting to emerge in North America due to the current resin supply pinch. Current coated-paper labels are supplied from Europe, but Muller is exploring North American sources. Molds for North America would still be built by Muller in Europe. Konowal explains that these tools have added complexity because every flow path requires tight shutoffs where not typically located. So far, molds with up to eight cavities have been built for this technology. IML automation would come from Switzerland and Colorado. Konowal adds that very accurate injection is required, along with a barrel undersized for the clamp tonnage, owing to the small amount of plastic injected. Netstal and Husky machines have been used successfully so far.

Related Content

-

Slimmer All-Electric Press Debuts

A slimmed-down version of Engel’s all-electric, e-mac injection molding machine is among eight displays, which also include LSR micromolding, quick mold changes and a cube mold.

-

In-Mold Labeling Applied to Medical

In collaboration with multiple partners, Arburg will showcase IML for centrifuge tubes at Fakuma 2023, eliminating printing or other downstream steps.

-

Completely Connected Molding

NPE2024: Medical, inmold labeling, core-back molding and Industry 4.0 technologies on display at Shibaura’s booth.