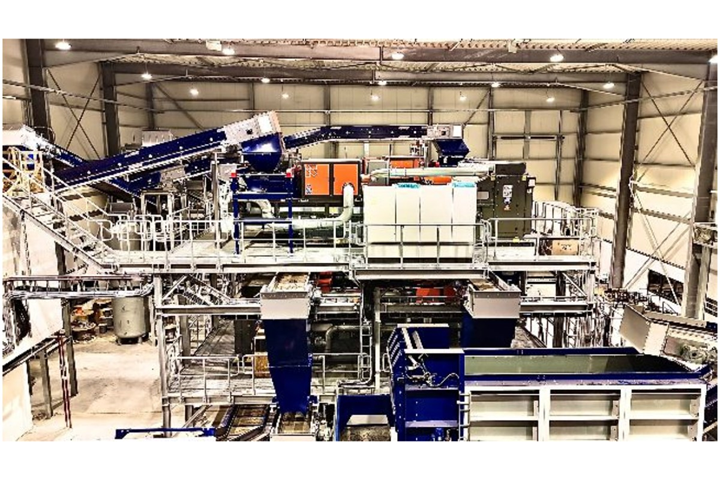

Source One Plastics Starts Up Plastic Waste Sorting and Recycling Facility

Dry processing method is used to reduce energy consumption.

Source One Plastics, a joint venture between 23 Oaks Investments and Lyondell Basell founded in 2022, has successfully started up its plastic waste sorting and recycling facility in Eicklingen, Germany. The new unit processes postconsumer plastic waste such as mixed plastic packaging and flexible polyolefins materials, which would otherwise be sent mostly to incineration facilities. The annual processing capacity is expected to be 70,000 metric tons (roughly 77,000 U.S. short tons).

The new plant will use a dry processing method to reduce energy consumption by up to 30% compared to conventional plastic recycling technologies. The system is designed to minimize the occurrence of fine plastic dust and its release into the environment. The plant is powered by locally generated, renewable energy. The plastic waste processed in Eicklingen will provide a material part of the feedstock for the first commercial-scale, catalytic advanced recycling plant that Lyondell Basell will build at its Wesseling, Germany, site.

“This marks another important milestone in our strategy to transform recycled material into high-quality polymer. This state-of-the-art advanced sorting facility will turn postconsumer, mixed plastic waste into feedstock for our integrated hub in Cologne area,” says Yvonne van der Laan, executive vice president, circular and low carbon solutions for Lyondell Basell. “There, we will use cutting-edge technologies to close the loop of plastic materials and create sustainable solutions for society.”

The Source One Plastics joint venture will provide a broad portfolio of services to procure, sort and pretreat waste plastic to deliver feedstock suitable for advanced recycling. Through advanced recycling, Lyondell Basell is producing polymers for a range of applications.

“With the help of AI technology, our system will detect and sort material composites with product-specific accuracy,” says Kai Hoyer, owner of 23 Oaks investments.

Related Content

-

Looking to Run PCR on a Single Screw? Here’s What to Keep in Mind

Just drop it in and mix it up? Sorry, there’s a lot more to it than that. Here is some of what you need to consider.

-

A Recycling Plant, Renewed

Reinvention is essential at Capital Polymers, a toll recycler that has completely transformed its operation in a short period of time.

-

Scaling Up Sustainable Solutions for Fiber Reinforced Composite Materials

Oak Ridge National Laboratory's Sustainable Manufacturing Technologies Group helps industrial partners tackle the sustainability challenges presented by fiber-reinforced composite materials.