Arburg Updates Machine Control

Arburg announced a series of updates to its Gestica conrol platform, including the addition of new “assistants” and “pilots.”

Arburg says its Gestica control platform has upgraded its navigation and sequence editor, resulting in faster, more efficient cycles, according to the company, as well as improved reliability via interlocking of functions. Arburg says the goal is for the controller to “know” its environment using assistance functions.

These assistants include aXw Control FillAssist, aXw Control MeltAssist, aXw Control CycleAssist, and aXw Control EnergyAssist. The aXw Control FillAssist uses imported STL data to create a filling study, which defines appropriate injection parameters. aXw Control MeltAssist identifies the installed cylinder module from a chip and uses this data to calculate parameters automatically.

The new aXw Control CycleAssist knows the programmed cycle sequence and graphically compares the current times of each cycle step with previously defined reference values. aXw Control EnergyAssist knows when production is scheduled to start and when it will end, and it is controlled automatically to ensure a uniform, energy-saving process.

In addition to “assistants”, the Gestica control also deploys “pilots” for adaptive process control and regulation. aXw Control ScrewPilot ensures a stable filling process by regulating the position of the screw. aXw Control PressurePilot reportedly makes mold filling more consistent and improves balance. aXw Control ReferencePilot controls the holding pressure curve in real time via a pressure sensor in the mold. Besides improving part quality reproducibility, this also reduces start-up cycles.

The newly developed Arburg FlowPilot combines a cooling water manifold close to the mold with temperature and flow control. This allows interference variables such as clogged filters, cooling channel deposits, and kinked lines to be identified and corrected.

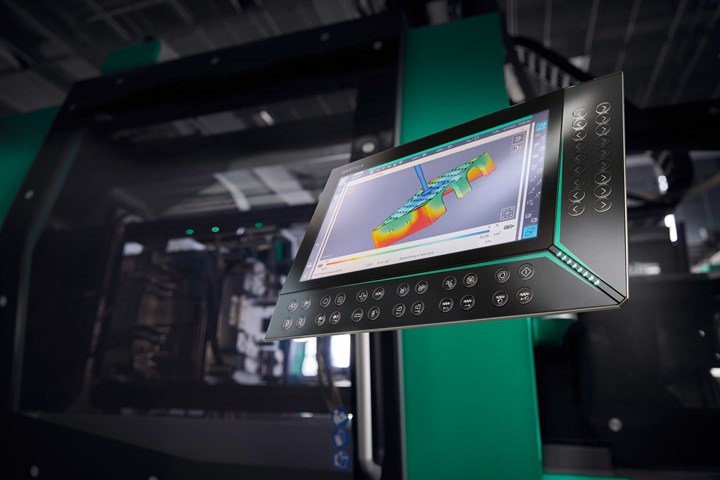

Mimicking today’s smart phones in terms of the user interface experience, the Gestica control has two separate computers for operation and process control, including Multicore technology. In addition to boosting operational reliability, Arburg says this setup also provides protection against unauthorized external access. Also, since Gestica has a closed operating system, no security updates are needed. Arburg says it’s easy to integrate printers, USB memory units and browsers.

The touch screen comes in a 16:9 format with full HD quality, multi-touch technology for gesture control, a glass front with integrated hardware keys, and a special light design for status feedback signals. The EASYslider feature allows movements to be controlled flexibly and intuitively during set-up. Applying OPC UA-based connectivity, the Gestica control system allows entire production cells to be managed providing simple communication with higher-level systems.

Arburg’s Gestica control features the aXw Control FillAssist.

Related Content

-

How to Reduce Sinks in Injection Molding

Modifications to the common core pin can be a simple solution, but don’t expect all resins to behave the same. Gas assist is also worth a try.

-

How to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection there are many variables that can dictate the best option.

-

A Simpler Way to Calculate Shot Size vs. Barrel Capacity

Let’s take another look at this seemingly dull but oh-so-crucial topic.

(2).jpg;maxWidth=970;quality=90)