Compact Screen Changers for Processing PCR

NPE2024: W. Müller shows off new screen changers in response to increasing interest in blow molding recylates.

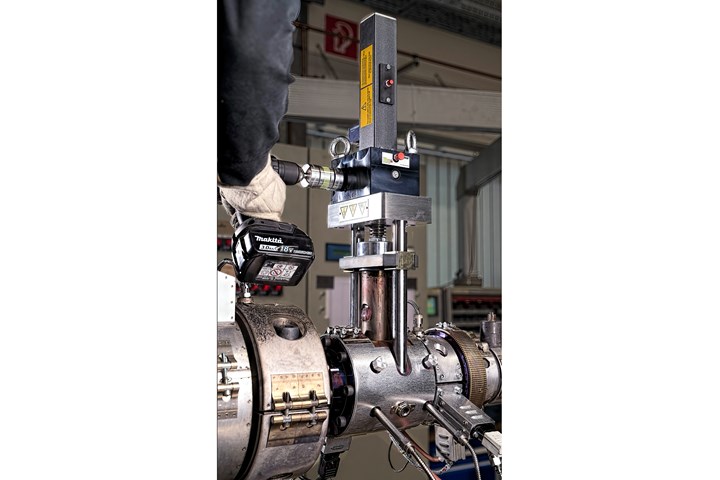

W. Müller’s new screen changers are said to be space-saving and retrofittable on vertical or horizontal extruders, and safe to operate manually. (Source: W. Muller USA)

“We are receiving more and more inquiries from North, South and Central America about systems for safe recyclate processing,” reports Jens Schlueter, president of W. Müller USA. Hence, the company is introducing a new generation of screen changers for its blow molding extruders. W. Muller considers melt filtration to be essential to controlled extrusion — and never more so than when processing postconsumer recycle (PCR).

The new screen changers can be retrofitted and do not require any special safety measures because they do not have their own drive. They can be operated manually or with a power tool, such as a cordless screwdriver. These screen changers are designed to be particularly space-saving because they are integrated into the connection piece between the extruder and extrusion head. The extruder length is not significantly extended, the company says. In addition, the screen changer can be installed in any orientation, including vertical extruders.

For PCR processing, W. Müller offers the ReCo3 system with three independent extruders, mounted vertically. The PCR layer is sandwiched between two virgin layers. According to Schlueter, “Traditionally, there are no screen changers for such extruders. We are one of the very few suppliers on the market. Normally, the changers are too long to install vertically without risking the stability of the extruder.”

Adds Mario Jardin, director of Aftermarket and Service, “I see how operators frequently struggle with leaks and injuries when trying to operate traditional screen changers, due to the heaviness of these systems, which often tend to jam. The operator-friendly piston design of our screen changer eliminates the room for leakage and does not seize. This reduces screen-changing times significantly.”

Related Content

-

Avoid Four Common Traps In Granulation

Today, more than ever, granulation is an important step in the total production process. Our expert explains a few of the many common traps to avoid when thinking about granulators

-

How to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

-

Recycled Material Prices Show Stability Heading into 2023

After summer's steep drop, most prices leveled off in the second half.

.png;maxWidth=300;quality=90)

(2).jpg;maxWidth=300;quality=90)