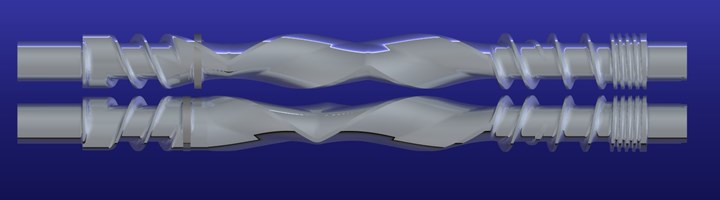

High-Dispersion Rotor for Compact Processor

Billed as ideal for processing fiber grade, high color carbon black, and color concentrates.

At K 2022, FARREL POMINI will introduce the High-Dispersion (HD) Rotor for use in the company’s full line of Compact Processors. Designed specifically for applications requiring high dispersion, this rotor is billed as ideal for processing fiber grade, high color carbon black, and color concentrates.

Photo: FARREL POMINI

The HD Rotor is a single stage rotor with an enhanced mixing area in a 10:1 L/D format. In addition to a mixing section that is double the length of the standard FARREL POMINI rotor, the HD rotor includes:

- A new concave feed flight design which increases the conveying efficiency at the infeed of the mixer using high rotor speeds aiding intake of lower bulk density materials.

- Once inside the mixer, the new partial double feed flight design with increasing pitch maximizes throughput rate and allows for even distribution of material over both rotor tips.

- The use of rotor cooling on the new double length mixing section increases the residence time of the material in the semi-molten state. The resulting higher material viscosity increases energy input to maximize dispersive mixing.

- A wider apex region increases material exchange between both rotors which better distributes material in the mixer to increase the homogeneity of the compound.

- New offset blister rings on each rotor with an adjustable dam are used to throttle material from the mixing section, allowing for the adjustment of residence time.

- A pumping section located downstream of the blister ring improves venting performance by efficiently moving material out of the mixer through the orifice.

Related Content

-

Tosaf’s Investments in North America Result in 40% Increase in Production Capacity

Backed by a global presence, Tosaf provides localized additive and color solutions, and services for the plastic industry in North America.

-

Additive Masterbatch for Permanent Etching on Black and Dark Plastics Products

Ampacet’s new ColorMark reveals color in dark plastic surfaces exposed to laser light

-

Techmer Buys Advanced Color Technologies

Deal will expand Techmer’s in colorants and additives in synthetic fibers.