Mold Maintenance

Latest Mold Maintenance Articles

VIEW ALLAmerican Injection Molding Institute Opens Mold Maintenance Classroom

The Beaumont subsidiary has opened the Mold Maintenance Center of Excellence classroom at its Erie, Pennsylvania, headquarters.

Read MoreMold-Channel Cleaning Equipment Gains North American Distributor

PCS Company is now offering Polish firm FADO Group’s CoolingCare system for automated mold-channel cleaning.

Read MorePressure Tester Checks Molds for Water Leaks

Globeius is offering the Mouldpro pressure tester for detecting water leaks within an injection mold’s cooling circuit.

Read MoreMold Maintenance, Tooling Know How

The ability of technicians in an injection molding shop to fix, modify or upgrade a mold has a huge impact on that company’s bottom line. With this collection of content, we’ve bundled some of the very best advice on repairing and maintaining injection molding machines.

Read MoreAIM Institute Adds Mold Maintenance Training Courses

The American Injection Molding (AIM) Institute, part of the Beaumont Family of Companies, will now offer mold maintenance training courses, following the acquisition of that business from Moldtrax.

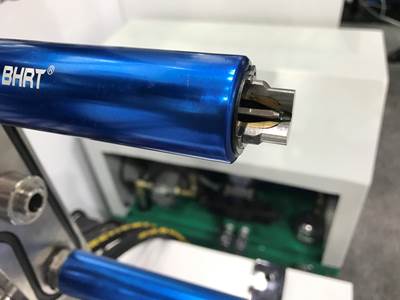

Read MoreHot Tip Sprue Cleaner Unclogs Sprue Bushings and Tips

Globeius’ Hot Tip Sprue Cleaner provides a flexible, hand-held tool for melting thermoplastics from plugged sprues and nozzles.

Read MoreLatest Mold Maintenance News And Updates

Descaling Pump Cleans Heating and Cooling Circuits

Mouldpro’s compact and portable descaling pump keeps heating and cooling circuits on molds and molding machines clear of rust and limescale deposits.

Read MoreCold Jet Builds New Cincinnati Headquarters

Cold Jet is consolidating two Cincinnati-area facilities into one location.

Read MoreHigh-Performance Universal Lubricant

Nanoplas says MIN-LUBE high-performance grease is designed for severe environments, as well as food and pharmaceutical related spaces.

Read MoreCPT to Offer Mold-Handling Equipment

Cincinnati Process Technologies (CPT) has partnered with German firm RUD (Aalen) to offer that company’s full line of mold-handling equipment in the U.S. and Canada.

Read MoreTool Storage and Handling System Supplier Names Globeius as North American Distributor

U.K.-based Rack-Storage Ltd. will use Globeius to distribute its custom-built heavy and light duty tool storage products throughout the U.S., Canada and Mexico.

Read MoreMold Location System

Hasco’s Loc Check A5900/ is a magnetically mounted device that allows users to locate a mold wherever a mobile phone network is available.

Read MoreFeatured Posts

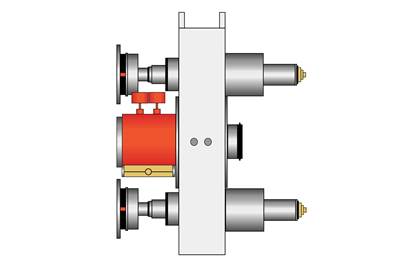

System Offers 'Lights Out' Mold-Channel Cleaning & Diagnostics

New system automatically cleans mold-cooling lines—including conformal channels—removing rust and calcium, among other deposits, while simultaneously testing for leaks, measuring flow rate and applying rust inhibitor.

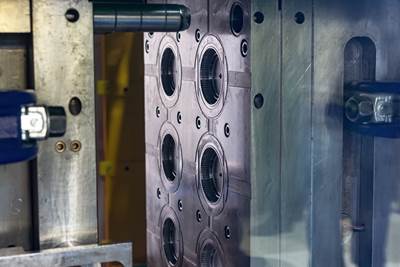

WatchHow to Mount an Injection Mold

Five industry pros with more than 200 years of combined molding experience provide step-by-step best practices on mounting a mold in a horizontal injection molding machine.

Read MoreMolders’ Block: Dealing With Foreign Materials in a Hot-Runner System

Understanding plastic flow can help you understand how foreign materials move—or don’t move—through your hot-runner system.

Read MoreDesign Your Tools for Moldability ... and Maintenance

In the initial design phase, when considering the structure and elements of the tool, are you designing them to be maintenance friendly? Canon Virginia has used this approach and preventive maintenance to make tool replacement a thing of the past. You can, too. Here’s how.

Read MoreHeard of Design for Manufacture…How About Design for Maintenance?

Contract manufacturer Canon Virginia (yes, that Canon) used a webinar to introduce what it calls DFM2— Design for Manufacture and Design for Maintenance.

Read MoreNew Mold Grease Smooths Operations for Troublesome Tool

Switching to a new synthetic grease helped an injection molder keep a difficult die running, eliminating unplanned downtime and cutting scrap.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)