Blow Molding: New Machines Take on Challenging Shapes

From very small to very large, from hotel amenity bottles to automotive jounce bumpers, new and upgraded machines tackle difficult jobs while improving productivity, quality, and energy efficiency.

Some two dozen new or enhanced machines of extrusion blow shuttle, suction blow, injection-blow, and one- and two-stage stretch-blow types at the show—plus other new developments in extruders, tooling, and controls—indicated a healthy level of innovation in blow molding. While many of these developments are aimed at increased productivity and energy savings (witness the many all-electric, hybrid, an servohydraulic entries), a number of them are tailored for production of unusual or challenging shapes.

EXTRUSION BLOW NEWS

Our show preview in September highlighted new all-electric and hybrid shuttle machines for larger packaging items. The new electric KBB 200 and 400 machines from Kautex Machines, Inc. (U.S. office in North Branch, N.J.) and the hybrid EBlow 37 from Bekum America Corporation (Williamston, Mich.) are aimed particularly at 20 L jerrycans and canisters. In addition, the new all-electric M-Series shuttles from Uniloy Milacron LLC (Cincinnati) come in a range of sizes for products from 100 ml up to 20 L (see November Keeping Up).

Another new large all-electric shuttle machine at the show was the Hesta700 from Hesta Basformtechnik GmbH of Germany. This completely redesigned double-station machine is the company’s largest model. It has a 22-m.t. clamp with opening stroke of 240 mm and max. mold size of 680 x 400 mm. During blowing, the drives are shut off completely, enabling energy savings of more than 40%, according to the company. There are no mechanical settings of mold stroke, opening stroke, closing movement, or calibration stroke. Patented automatic stroke settings equal out different mold thicknesses, different heights, and wear-related tolerances in the system. Quick tool changes—typically in 15 min—are due to plug-in components and absence of cooling hoses to remove and reconnect, as the molds are cooled directly from the back side.

Meanwhile, BBM Maschinenbau of Germany has been making electric single- and double-station shuttles for jerrycans (up to 40 L) since 2007. The firm is evidently interested in the North American market, since it exhibited at the last two SPE fall Blow Molding Conferences.

Other news for jerrycan and canister production comes from W. Müller GmbH of Germany (W. Muller USA, Inc., Agawam, Mass.). The company introduced a new vertical 38/29D satellite extruder capable of more than 55 kg/hr (121 lb/hr) of HMWPE at 100 rpm, suitable for the inner and outer layers of trilayer stackable canisters. Such coextruded containers could replace standard UN-certified monolayer containers while cutting costs by using a 60-70% inner layer of recycled or unpigmented virgin resin. Working with German extruder supplier Gifa, Müller has supplied thousands of small vertical extruders but needed a larger model for the canister application with high-viscosity HMWPE. Normally this would require a bulky horizontal extruder, but Müller and Gifa modified the feed, metering, and mixing sections to come up with a compact vertical model with a 35-hp servo drive. Total head throughput of at least 300 kg/hr (660 lb/hr) can now be achieved, and Müller believes that can be increased by raising screw speeds beyond 100 rpm.

In addition, W. Müller has released data on recent experiments with its developmental trilayer foam-core technology, which injects nitrogen gas in the head. Testing mechanical properties such as topload for jerrycans reportedly indicates that foaming with solid inner and outer layers can retain 90% of solid properties at 20% weight reduction.

In other extrusion blow news, Kautex introduced its first dedicated suction blow molder for low-flash 3D parts such as automotive ducts. Model KSB10 has a 10-metric-ton clamp. The machine’s compact design occupies 50% less floorspace, and its modular construction allows shipping in standard containers. It’s the company’s first model with a servohydraulic system. It can change RWDS head tooling in 5 min. The extruder (with beltless drive) and die-head platform is electrically adjustable on xyz axes and has position memory. Four machines have already been sold, and three are running. Parts can be discharged to the left or right, and the removal gripper is servo driven.

For very high outputs of small containers, Magic mp SpA of Italy introduced its all-electric ME-L20/D-1300-T35 double- shuttle machine, its largest ever. It carries a 35-ton clamp with 1400-mm stroke, and 24 heads in two independent groups of 12. The twin 24-cavity molds have 50-mm center distances for 200-ml yogurt containers. (It can also run 20 heads for 500-ml yogurt containers.) The two heads are fed by two independent 90-mm extruders. Cycle times are pegged at 9 sec (±1 sec) for 200-ml and 500-ml containers, yielding 20,000 and 16,000 pieces/hr, respectively. Magic also announced that it will start up its first U.S. office, Magic North America, in Ann Arbor, Mich., around midyear (see Starting Up).

Ossberger of Germany, represented here by FGH Systems, Inc., Denville, N.J., showed off the Pressblower DSE 260, which has been newly upgraded for production of automotive jounce bumpers (or spring aids) of DuPont’s Hytrel copolyester TPE, replacing older designs of non-recyclable rubber or microcellular PUR, or PP filled with PUR foam. The unit now can produce articles weighing up to 250 g, vs. 140-150 g previously.

INJECTION-BLOW VARIATIONS

In September, we previewed the main new entry in injection-blow molding (IBM), a series of four servohydraulic models from Jomar Corp., Egg Harbor Township, N.J. We also noted that three suppliers of injection molding machines would show systems adapted for injection-blow molding. In all three cases, the adaptation was in the mold, not the machine (other than the control programming):

• Boy Machines Inc. (Exton, Pa.) used a mold from Schreck Kunststofftechnik GmbH of Germany in a Boy 60 E press (see October Keeping Up). The hot-runner mold has an indexing plate that injected four PE preforms for an eyedrops container, then rotated 180° to blow four small bottles in a cycle time of 18 sec. This medical cell automatically packaged each shot of bottles in a sealed pouch.

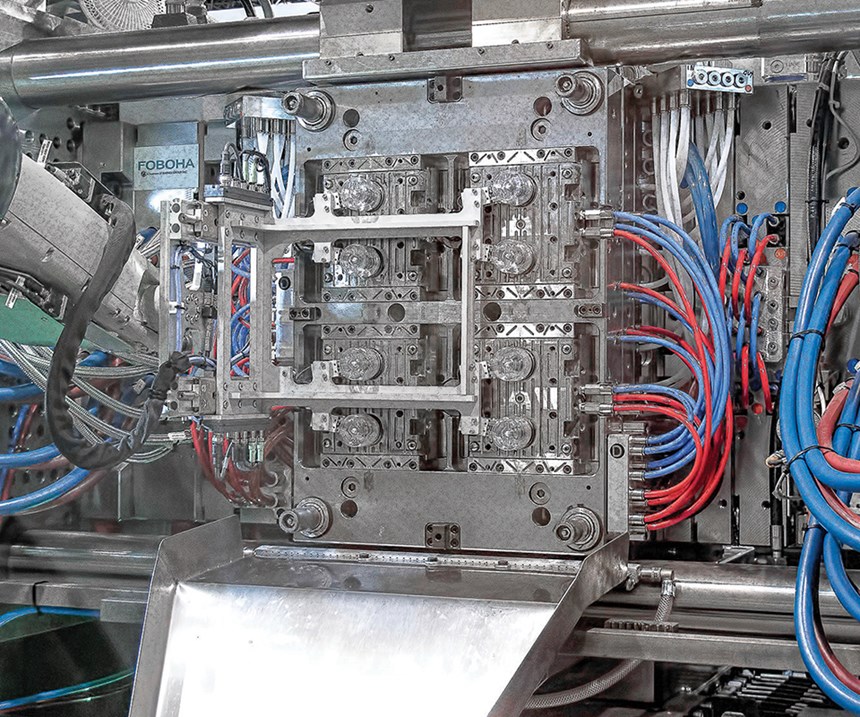

• Engel Machinery, Inc. (York, Pa.) mounted a spin-stack cube mold from Foboha USA Inc. (Beverly, Mass.) to mold 8 + 8 preforms and bottles from PP or PET on an e-motion 220 T electric press. The electric turntable rotated in 90° increments. After injection, the second station (facing the operator side of the machine) preheated the preforms for blowing in the third sta- tion (180° opposite to injection). The finished bottles were removed in the fourth station (back side of the machine) by an Engel easix six-axis robot. Cycle time was 7 to 8 sec. This was considered a proof-of-concept demonstration for major Austrian packaging producer Alpla. Unlike standard IBM systems, Engel says this concept could be expanded to 96 cavities.

• Wittmann Battenfeld, Inc. (Torrington, Conn.) molded PP flasks in a 2 + 2 mold with an indexing plate from Grosfilley of France (grosfilley.fr), which was mounted on a standard servohydraulic SmartPower 240. Grosfilley has built several such molds for small to medium-size bottles with up to 4 + 4 cavities using PP, PET, and PC. The K show demo ran at 15 sec, but the moldmaker said it can run 2 sec faster.

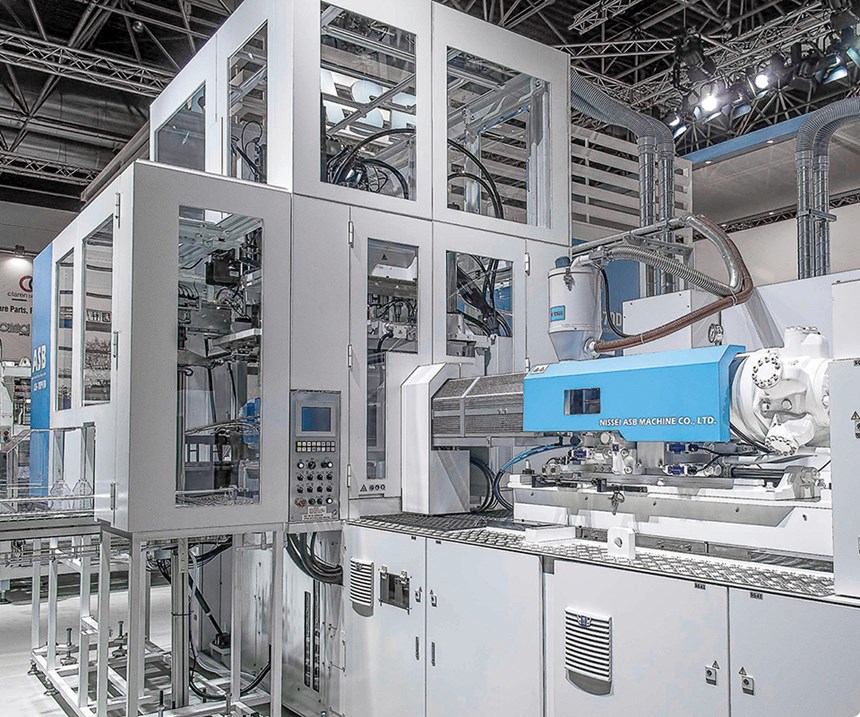

In addition, Nissei ASB Company of Japan (U.S. office in Smyrna, Ga.) introduced its first IBM system without stretching. This new variant of its ASB-12M one-step injection stretch-blow (ISBM) system (ASB-12M/IBM) uses only two stations of the four-station turntable but is convertible to stretch-blowing. The 12-ton servohydraulic machine boasts an advantage over conventional IBM systems in that its unique vertical clamp eliminates preform sag and parting lines on the sides of the preform.

LOTS OF STRETCH-BLOW NEWS

Nissei ASB Machine Co. of Japan (see above) brought several new developments to the show. One was a version of the PF-24-8B/12, a so-called “1.5-step” ISBM system, intended to combine the best of both one-step and two-step processes to achieve high output rates in a compact footprint. The linear system has 12 preform cavities and four blowing cavities, and accumulates the preforms, which are allowed to cool only to the glass-transition temperature before blowing. A new sequencing system combines batch molding and cooling of preforms with continuous oven heating.

The enhanced model at the show had several other new features. One was the ability to mold a deep pinch-style handle in large PET jugs. An external add-on hydraulic power unit is used to drive forming parts within the blow mold so that the shape of the cavity changes during blowing, reportedly allowing production of shapes that were formerly “impossible.” The same mechanism can also add inserted

PP or HDPE handles that are mechanically locked into the the bottle during blowing. Another new feature is neck orientation (i.e., positioning) with an integrated register on the neck of the preform to enable alignment to a specific thread position before entering the blowing station. This feature is said to be valuable with ovalized preforms for high-ovality or pinch-grip containers and for containers with flip-top caps or closures with some sort of pouring aid.

The machine at K was molding 3 L pinch-grip bottles at 1800/hr, though the machine is capable of up to 2400/hr. It was servohydrauli- cally operated, which reportedly is becoming standard for the company since NPE2015. The first machine of this type in the U.S. will be installed at the company’s recently expanded technical center in Georgia. It will be capable of molding 500-ml water bottles at up to 10,000/hr.

Also at the show was a version of the firm’s best-selling ASB-70DPH ISBM one-step machine with a new double-blow system for heat-set PET containers. Previously, that feature was only available on two- station machines, according to the company. The new ASB-70DPH/ DB is a “mid-range” 70-ton machine for molding bottles for sauces and vitamin drinks that require hot-filling at 85-90 C (185-194 F). This four-station rotary machine accommodates two blowing cycles per injection cycle using two sets of molds in the blowing station with a servo-driven shuttle. Cycle time is said to be unaffected by double blowing. The machine has servohydraulic drive and air recycling for energy savings. Injection clamp daylight has been extended up to 700 mm for molding longer preforms of non-PET resins, and an optional injection unit offers added capacity.

A new ISBM model from Aoki Laboratory America, Inc. (Elk Grove Village, Ill.) is the SBIII-300-30 for high output of small, narrow-neck containers. It produced 35 ml round bottles with a 13 mm neck (such as for mascara, hotel amenities, product samples, etc.) in 32 cavities on an 8.2-sec cycle for more than 14,000/bph—the highest output yet for the company.

Also new was the SBIII-300-50, Aoki’s first servohydraulic machine, which boasts a faster dry cycle as well as energy savings. It molded a heavy (31.1-g, 6-mm-thick) preform for 8-cavity cosmetic containers in 14.24 sec (2008/hr), vs. 30 sec previously. Improved preform design contributed to the faster cycle. Another advantage is that this new system allows use of standard PET with such a thick- walled preform, which previously required much more expensive PCTA polyester to prevent crystallization and loss of clarity.

Magic of Italy (see above) showed off a new all-electric ISBM machine—its first rotary-style model. The MTM 152 has a 12-m.t. clamp and 250-cc injection capacity. The four-station machine can mold products from 20 ml in eight cavities up to 2.5 L in one cavity.

Magic’s linear ISBM machines also come in two new models for large containers. The BME 156 is aimed at 3 L bottles with pinch grips; the BME 170 (the largest in the series) molds 8 L wide-mouth jars in two cavities.

As reported previously (October Starting Up), a relative newcomer to one-step ISBM machines is Austrian moldmaker Mould & Matic Solutions, now part of Germany's Kiefel (US: Kiefel Division, Brueckner Group USA). The firm showed the latest evolution of its Blowliner ISBM for PET and PP bottles and wide-mouth jars. This system is based on an Engel injection unit with linear transfer of the preform, which is clamped from the inside, using simple aluminum grippers, and held throughout the entire process. Injection and clamping func- tions are servohydraulic, while the rest are servoelectric. Servo control allows stretch-blowing to be profiled. Other capabilities are oval necks, integrated handles, flexibility to run one to four rows of preforms in the same machine, and simple conversion from mono- layer to multi-layer containers. New features include Engel’s CC300 controller with large touchscreen and upgrading of the stretching function from hydraulic to servoelectric.

The firm has sold 11 units in Europe and is now pursuing markets in the Americas. Blowliner comes in three sizes:

• Blowliner S has 60-ton injection clamp (100 ton optional), 20-ton stretch-blowing clamp, and 300 g PET shot capacity (500 g optional). It is aimed at 0.75 to 3 million pieces/yr.

• Blowliner M has 100-ton injection clamp, 40-ton stretch-blowing clamp, and 600 g shot capacity (800 g optional). It’s for 3 to 20 million pieces/yr.

• Blowliner L has 250-ton injection clamp (400 ton optional), 40-ton stretch-blowing clamp, and 600 g shot capacity (3 kg optional). Its range is 10 to 30 million pieces/yr.

SIPA North America, Inc. (Atlanta) has a new series of one-stage, rotary, four-station ISBM systems. These are relatively low-output systems for 300-400 large containers/hr up to 5000-7000 small (20-40 ml) refills for e-cigarettes/hr. Model ECS SP 50 has a 50-ton clamp, up to 12 cavities, max. container size of 5 L, 80-mm max. neck diam., and max. output of 5400 bph. Model ECS SP 80 has an 80-ton clamp, up to 16 cavities, max. container size of 8 L, 110-mm max. neck diam., and max. output of 7200 bph.

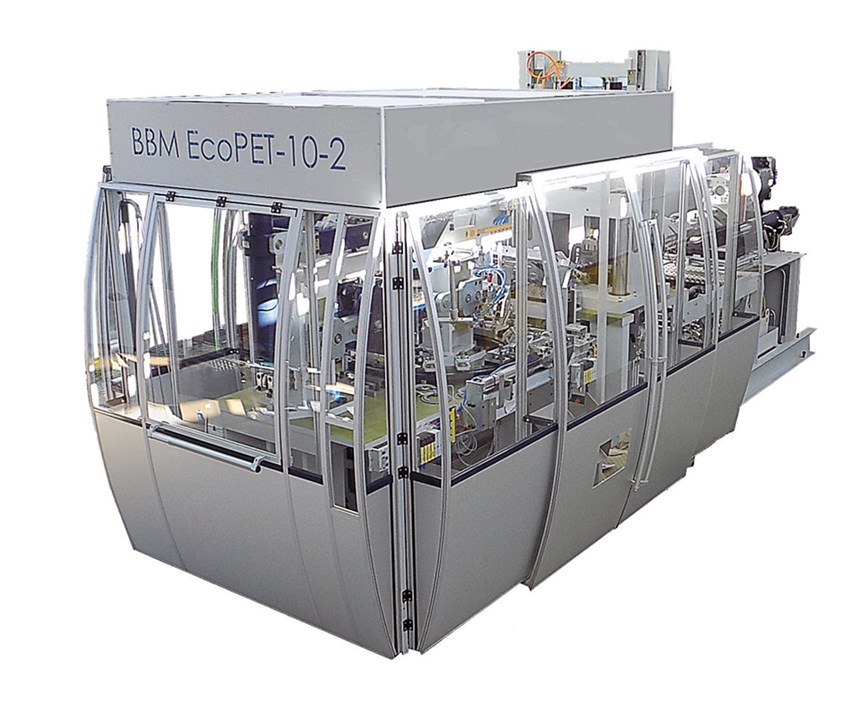

BBM Maschinenbau of Germany (see above) introduced its all-electric EcoPET machine in two versions, model 10/2 (10 injec- tion cavities, two stretch-blow cavities) and 5/1. This linear system provides continuous plastication with a melt accumulator, preferential heating of oval or rectangular bottles, controller with multi-touch screen, and remote servicing via the internet. EcoPET 10/2 can mold bottles from 50 ml to 2 L at up to 2000 bph (1.5 L); model 5/1 can produced 1 to 5 L bottles at up to 800 bph.

In two-stage (reheat) stretch-blow machines, KHS Corpoplast (U.S office Waukesha, Wis.) is offering numerous “next- generation” enhancements to its popular InnoPET Blowmax Series IV. These include wide-mouth capability (reportedly unusual for a rotary machine); preferential heating for oval containers; and hot-fillability up to 96C (205F).KHS is also extending the range of its Plasmax glass-barrier coating systems at both ends of the productivity range, which is currently 12,000 to 40,000 bottles/hr. For small linear machines, Plasmax systems are now available for 4000 to 8000 bph. And at the high end, its Plasmax Plus system can achieve up to 46,000 bph for heat-set and carbonated soft-drink bottles, both of which must withstand flexing.

The smallest reheat SBM machine at the show was from 1BLOW S.A. (U.S. office Duluth, Ga.), which also exhibited at NPE2015 (see June ’15 show report). It has sold 15 of its extremely compact machines (about the size of two old-fashioned telephone booths, but with room for a person to step inside the machine from two sides) in the U.S. and two in Mexico. The newest development is remote servicing and diagnostics via internet connection on the machine. One specialty of this system is its ability to tackle difficult bottle shapes (see Starting Up).

The company also showed off some recent demonstrations of the unusual capabilities of this machine, such as PET bottles with very narrow (22-mm) necks or oval bottles with offset neck and gate. In the latter case, preferential heating allows PET to replace extrusion blown PVC bottles for automotive fuel additives. Two other capabilities said to be difficult for reheat machines are very flat (90°) shoulders and neck orientation to align a flip-top cap with the parting line (or at 90° to the parting line) on oval bottles for ketchup or deter- gents. While other systems achieve this with the aid of a notch or tab molded into the preform neck, 1Blow can use any standard preform: A very inexpensive rotating screw mechanism finds the thread start.

Meanwhile, SACMI of Italy (U.S. office Des Moines, Iowa) says it is close to qualifying PET and PP on its unique rotary-wheel compression blow forming (CBF) system (see July ’12 and May ’15 Close Ups), which up to now has used HDPE and PS for pharmaceutical and dairy containers. Some 15 CBF systems are in use, four of them in the U.S. SACMI currently offers two versions with 16 or 20 stations and is working on a lower- volume system with eight stations. It is also working to satisfy demand for wide-mouth capability for food containers.

The company is also gradually improving cycle times. Currently, a 16 g HDPE pharma bottle can run on a 20-station machine at 150 bpm, up 20% from three years ago. Current cycle time of 8 sec is said to be 5-6 sec faster than conventional injection-blow systems.

Related Content

Automotive Awards Highlight ‘Firsts,’ Emerging Technologies

Annual SPE event recognizes sustainability as a major theme.

Read MoreABC Technologies to Acquire Windsor Mold Group Technologies

The Tier One automotive supplier with compounding and blowmolding machine capabilities adds the 50-yr-old molder and moldmaker.

Read MoreGetting Charged Up About Electric Vehicles

Metal-to-plastics replacement stories are a classic of the genre for plastics publishing, and nowhere more so than in the automotive space.

Read MoreImpacts of Auto’s Switch to Sustainability

Of all the trends you'll see at NPE2024, this one is BIG. Not only is the auto industry transitioning to electrification but there are concerted efforts to modify the materials used, especially polymers, for interior applications.

Read MoreRead Next

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More

.png;maxWidth=300;quality=90)

(2).jpg;maxWidth=300;quality=90)