A Piece of History Comes Home

Almost 50 years and 40,000 machines after it started making them, Milacron now has the third injection molding machine it ever built back in its possession and on display.

Going over the original purchase order for the press, which was dated August 7, 1968 and made out to Cincinnati Milling & Grinding Machines Inc., Milacron’s Tom Brown noted his company’s unusual mailing address. “Must have been before zip codes,” Brown said, reading aloud Milacron’s then postal code—Cincinnati No. 9, Ohio, U.S.A.—from the 45-year-old document.

Brown, VP of sales for Western North America at Milacron LLC, said the machine, a Cincinnati 375-ton, was headed 600 miles north and west from the company’s former Oakley, Ohio factory outside Cincinnati to West Des Moines, Iowa and Mid Central Plastics. Mid Central Plastics is known today as Innovative Injection Technologies (i2tech) and it remains a very good Milacron customer (taking delivery of a 3,300-ton Maxima G Servo machine last November), while Milacron’s Plastics Machinery operations are now located in Batavia, OH, and the once sprawling, 74-acre Oakley manufacturing site where press No. 3 was made was razed and is being redeveloped into a “multiuse space”, including apartments, shopping and a movie theatre.

Key account, long-lasting ties

Brown himself isn’t new to Milacron or plastics, starting with the company 26 years ago, although his first 23 years came on its extrusion side. When he moved over to the injection business three years ago, a meeting with i2tech, given its long history as a customer, came shortly thereafter.

“i2tech was one of the first customers I was introduced to,” Brown recalled. During those initial meetings, the historical significance of the i2tech’s oldest machine became understood, and Brown said Milacron took an interest in its future. At one point, there had been some talk of rebuilding the press for i2tech and displaying it at NPE 2012.

“For a variety of reasons, we decided to not pursue that,” Brown explained, “but we knew the machine was out there, and we started to work very closely with the ownership of the company.”

While selling i2tech some new machines in October of 2011, a pump on the aging press failed, and rather than replace the component, i2tech opted for a new 330-ton Roboshot that Milacron had in stock.

“It made sense to decommission the machine,” Brown said, “and replace it with something that was quite a bit more modern in terms of technology.” Over its 43 years of continuous service, the 375-ton 32-ounce shot machine, bearing serial No. 3, is believed to have been rebuilt twice, not counting when it was retooled for a Milacron open house in 2013. Prior to that gig, however, the then 45-year-old machine’s future was temporarily in doubt.

“When the new Roboshot was delivered to i2tech,” Brown remembered, “we had some conversations about what do we do with the old machine—everything on it had been completely used up. I2tech said how it had seen a nice long life for an injection molding machine, ‘Don’t you want this for historic reasons?’ [Cincinnati Milacron] does have an original machine tool from 1880s on display in a conference room, so the thought process was to do something like that, but this machine is a lot bigger.”

Eventually, the truck that delivered the new Roboshot to West Des Moines returned to Batavia, Ohio hauling Cincinnati No. 3, albeit to mixed reactions.

“A lot of folks said, ‘Are you crazy? What are we supposed to do with this?,’” Brown recalled, noting that the well-used piece of company history “sat in the back of plant” for some time before it found a new purpose.

On permanent display

“As we got ready for our open house last April,” Brown said, “we thought it would be a great machine to have on display, and we rebuilt it. Today, everything moves, it’s functional, but we’ve never hung a mold on it. We intend to keep it as a display piece.” (Refurbished No. 3 pictured below).

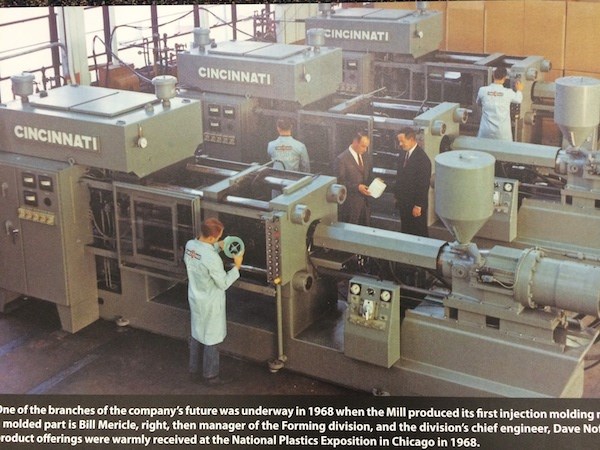

Originally building machines in threes, Milacron has a picture (above) of its newest display piece as it appeared freshly assembled and sitting alongside Nos. 1 and 2, newly painted army green.

August of 1968 was marked by several big news stories, perhaps most notably the unrest in Chicago the week of the 22nd, as the city erupted in violence during the Democratic National Convention held there. While Hubert Humphrey accepted his party’s nomination, the new Milacron press made its way west to Iowa, presumably by back roads (I-74’s Cincinnati terminus was 6 years from completion).

It was something else about the year 1968, however, that sparked recognition in Brown’s mind, who grew up in Michigan. “That’s the year the Tigers beat the Cardinals,” Brown said, recalling Detroit’s 4-3 World Series victory in October over the defending champion St. Louis Cardinals—a fact that’s perhaps fitting given that Milacron’s incorporation in 1884 came just 15 years after the founding of the first professional baseball team in 1869 in Cincinnati. (The ’68 Reds finished fourth in the National League with a record of 83-79).

Related Content

How to Set Barrel Zone Temps in Injection Molding

Start by picking a target melt temperature, and double-check data sheets for the resin supplier’s recommendations. Now for the rest...

Read MoreKnow Your Options in Injection Machine Nozzles

Improvements in nozzle design in recent years overcome some of the limitations of previous filter, mixing, and shut-off nozzles.

Read MoreHow to Stop Flash

Flashing of a part can occur for several reasons—from variations in the process or material to tooling trouble.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More