Blow Molding Challenges Embraced at Metro Mold

“Others mold difficult parts. We mold the impossible.”

The project was to blow mold a container for a corrosive fluid used in electronics manufacturing. A tight seal was the critical necessity. Even the smallest leak could be catastrophic, causing thousands of dollars in damage. The product had to meet specs on 15 dimensions with stacked tolerances as tight as 0.010 in. Machining was not an option. Metro Mold leveraged its expertise from multiple processes—blow molding, injection molding, and compression molding—to come up with a modification of accumulator-head blow molding that could create geometries non-native to blow molding. “It took extensive DOEs (Design of Experiments) to make sure it would work,” says Myles Marquette, v.p. of Metro Mold’s Consumer & Industrial Div. “But we’ve had no dimensional returns in years.”

That’s all in a day’s work at Metro Mold & Design, Rogers, Minn. “On rare occasions, today’s OEMs need a highly creative and atypical manufacturing solution that their current supply base just simply can’t produce. Creating unique processes and achieving complex geometries and tight tolerances that often elude other molders—this is where Metro Mold really excels,” explains Greg Heinemann, CEO.

Metro Mold calls that “Manufacturing the Impossible.” Notes Marquette, “That’s how we got into molding—we came up with solutions when projects had failed elsewhere. Other people can mold difficult parts. ‘Manufacturing the Impossible’ means we step in when other good molders Can’t make it work. We provide the creative design input, improved quality, or cost reduction that makes a product viable for the OEM.”

43 YEARS OF PROBLEM SOLVING

Metro Mold was started by John and Carol Holland in 1973 as a moldmaking operation in their basement. The firm entered into injection molding in 2001, urged by its largest customer, which had struggled with another molder. “We were their only toolmaker, so they asked us to take on molding,” says Tom Holland, son of the founders and operations manager for thermoplastics. The firm got into blow molding with the purchase of the current headquarters plant from ICM Plastics in 2006.

Metro Mold today has four plants with over 200 employees:

• The headquarters plant houses Consumer & Industrial operations, encompassing injection, blow, and thermoset (injection, compression, and transfer) molding.

• A second plant in Rogers performs moldmaking and precision machining.

• A smaller tooling operation is located in Little Falls, Minn.

• The medical molding, machining, and assembly plant in Brooklyn Park, Minn., has been a focus of growth in recent years.

Injection molding, with 45 presses, provides the large majority of the firm’s revenues, but blow molding accounts for around 20% and is expected to be the faster-growing segment this year, owing to a number of new projects. “We had focused mainly on growth in medical for the last five years, but we have put renewed emphasis on growing Consumer & Industrial in the last six months,” says Marquette.

The headquarters plant employs 100 people, 20 of whom are dedicated to blow molding operations, which also share maintenance, quality, tooling, purchasing, etc. with other parts of the Consumer & Industrial business. There are nine extrusion blow molding presses, including three continuous-extrusion machines (one large Bekum machine and two from Techne) and six accumulator units (0.5 to 35 lb head capacity) from Graham Engineering and Uniloy Milacron. They are assisted by three six-axis robots (and one linear part remover) that perform secondary operations like trimming and routing.

“Our blow molding specialty is custom packaging for high-value or corrosive products,” says Marquette, such as chemicals for electronics manufacturing or medical sterilization. We also make dispensing containers for consumer products.” Part sizes can range from as small as 10 g up to 14 lb. The company blow molds mostly HDPE and also PP, but some jobs utilize engineering resins like glass-filled PC, PVDF, or copolyester. These are mostly short to medium-length runs, from as few as 30,000 parts to 250,000 per year, though consumer products can run into millions of parts.

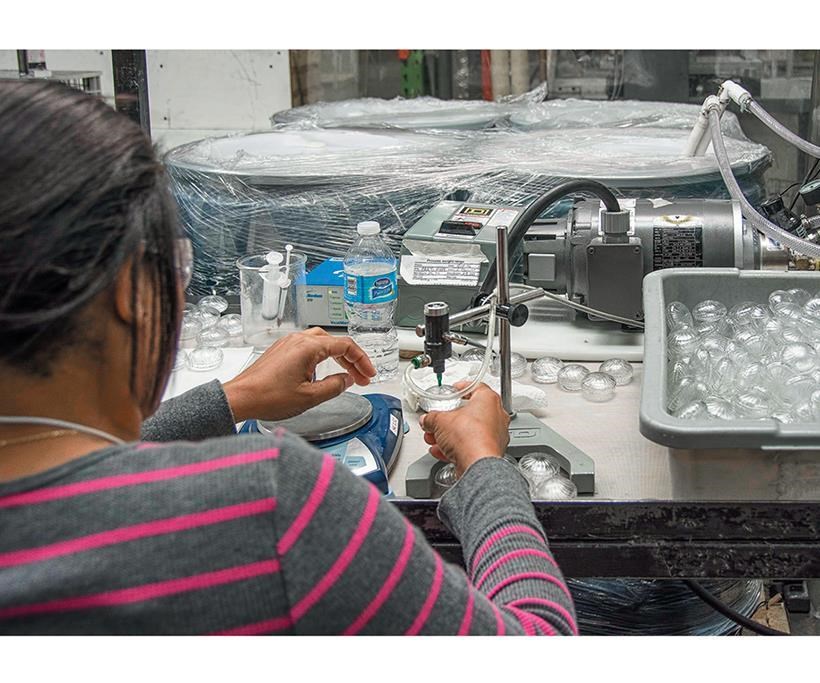

One of the consumer jobs is a brand-new product, made of clear copolyester, that looks like a flattened, ribbed sphere. It is designed to cool beverages without the diluting effect of ice cubes. The cooler contains a special solution; it is placed in the user’s freezer until the contents form a “thermal gel” and then it can be dropped into the beverage, where it sinks to the bottom. Metro Mold had to experiment with the correct amount of solution to make the product heavier than water but not so full as to crack the container when gelled. In a portable clean room, operators fill the blow molded cooler with solution and then sonic weld a plug into the hole.

One proprietary product is dock wheels weighing 12 or 14 lb, made entirely from reground HDPE from other jobs. They are molded on the plant’s largest machine, a Graham unit with a 35-lb head. After molding, the wheels are reamed to size on a drill press to produce a hole for the center axle.

Dock wheels are an exception to the company’s blow molding stock in trade. Says Christopher Peschke, operations manager for blow molding and thermosets, “In general, we do tight tolerances, such as holding wall thicknesses within 5 mils or part weight within less than 5%.”

Adds Marquette, “We have a lot of new blow molding business, and we get a lot of transfers from customers who have struggled with other blow molders. About 50% of our revenue comes from solving such problems. And we’re still price competitive.”

COMBINING MULTIPLE PROCESSES

Besides blow molding, the Consumer & Industrial Div. has 28 injection machines from 40 to 650 tons. Having multiple processes offers multiple advantages for Metro Mold. For example, the company combines injection and blow molding processes in the same product—injection molding one part and using it as an insert in a subsequent blow molding step. “We do it when we need a crisp feature for filling or sealing or an attachment point,” says Peschke. “In some years, such insert molding has accounted for 15-20% of blow molding sales.”

Another advantage is to be a “one-stop shop” for products that require assemblies of injection and blow molded parts. A prominent example is a consumer-product package that starts with a blow molded oval HDPE container. The dome and neck are trimmed off, and end caps that are two-shot injection molded of PP and TPE are snapped onto both ends of the oval. A dispensing closure of PP/TPE is adhesive bonded onto the side of the oval, in which a rectangular opening has been molded by a special process. Finally, a printed label with pressure-sensitive adhesive is applied all the way around the oval body, using a process designed to avoid any wrinkles or bubbles. “Although not typical, we used labels backed with pressure-sensitive adhesive so there will be no wrinkles or bubbles as the container shrinks after molding, to ensure a premium look,” says Marquette.

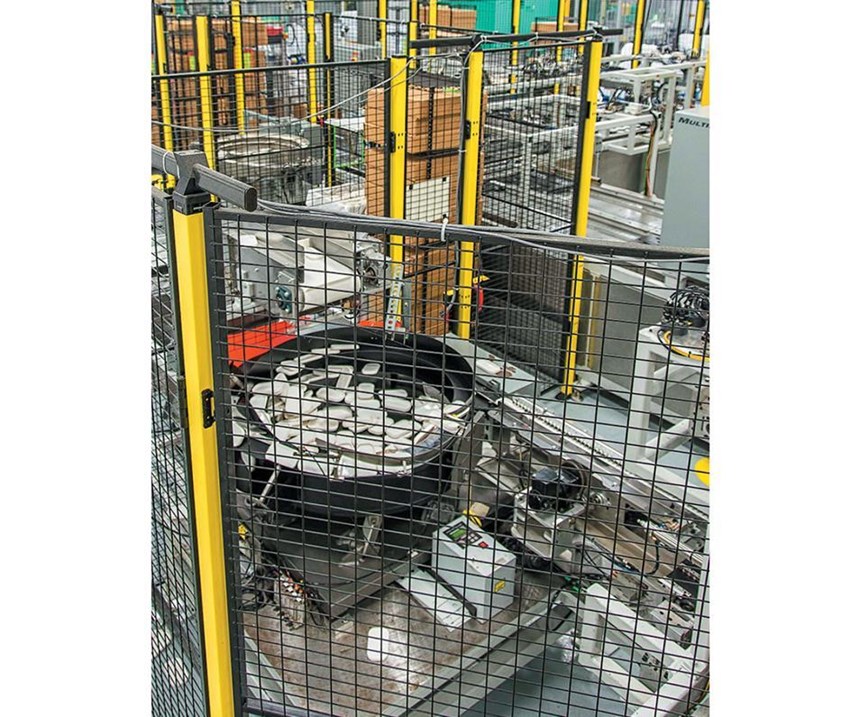

Metro Mold produces these packages in a fully automated cell that occupies an entire large room with two injection machines, the large Bekum blow molder (four heads and a two-sided shuttle), six vibratory feeder bowls, three vision systems, two 6-axis assembly robots, and one packing robot. In all, there are 42 stages to produce a finished pack—a five-part assembly plus label—every 3.5 sec, for millions of units a year. There are four different label patterns, and production is staged so that packs come off the line in sequences of all four label designs so they can be packaged together. The packs are filled with product, palletized, and stretch wrapped for shipping direct to the customer’s warehouse. All this takes place in a controlled environment with deionized air, positive air flow, and personnel wearing gowns, caps, and shoe coverings, so that it meets GMP standards for manufacturing cosmetics.

“It originally took 35 people to run the process, but with all this automation, it only needs six people,” Peschke says proudly.

Adds Marquette, “This is also an example of what differentiates our capabilities—using combined molding processes and very high-end mold technology for a consumer product that wouldn’t ordinarily get such high-tech treatment.” He is referring in part to a proprietary tooling technology that produces the dispensing opening in the side of the container during the blow molding process. “As compared with a normal approach of machining the side opening in a secondary operation, the in-mold process avoids the need for a robot and produces no particulates that would have to be cleaned out scrupulously. We developed the technique seven years ago and previously used it on a couple of other products.”

Tom Holland, who previously was operations manager for blow molding, cites another example: “We developed another special in-mold process to produce a tightly controlled I.D. for spigots used in laboratories. Typically, such a feature would be machined, but that requires deburring and thorough removal of fines.”

BETTER THAN SIX-SIGMA QUALITY

Along with tooling and processing creativity, Metro Mold’s chosen niche requires quality procedures not often seen in blow molding shops. Its quality procedures are adopted from the medical industry, including protocols for qualifying molds and processes, known as IQ-OQ-PQ (installation qualification, operational qualification, performance qualification). Some of its testing is also adopted from the electronics industry, since its containers for corrosive chemicals require U.S. Dept. of Transportation (DOT) approval.

“We do SPC on every product,” says Marquette. “That typically requires three runs of 32 shots each to determine Cpk and Ppk (process capability index and process performance index). We aim to beat the industry standard of Cpk 1.33, and we often get a Cpk of 2.5 or better.” A Cpk of 1.33 translates to 99.99% good parts, or 63 ppm rejects, equivalent to 4 sigma. A Cpk of 2.0 means at most 3.4 ppm rejects, or 6 sigma. Cpk of 2.5 is considerably better and not even defined in most quality literature.

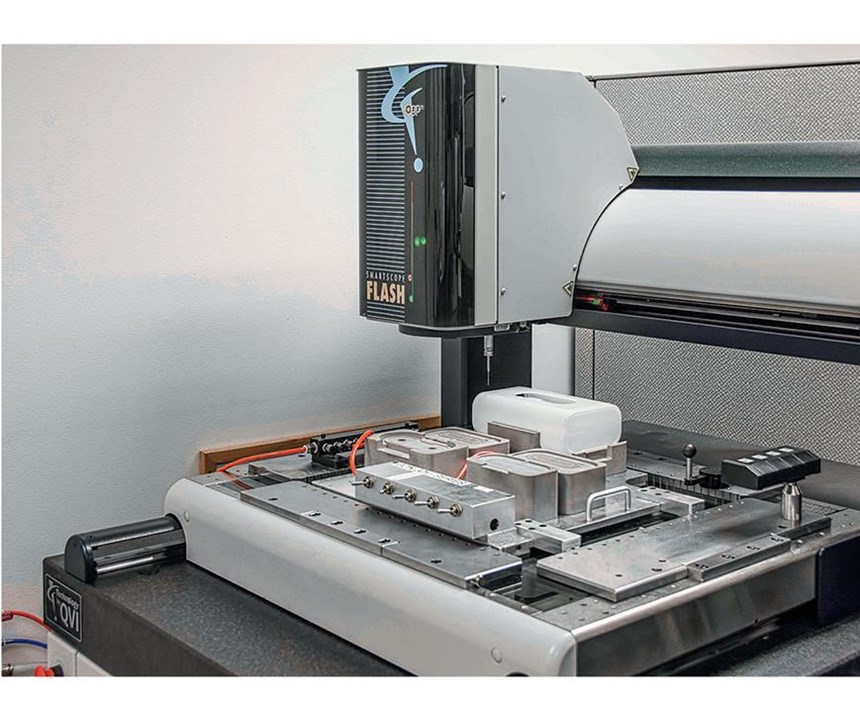

Quality manager Dan Ciatti has a lab most blow molders might envy. It has CMMs to perform dimensional checks (15 points on the blow molded consumer-product container, for example), and Magna-Mike wall-thickness gauges. On the manufacturing floor, dimensional checks can be made with calipers, vision systems, or custom-built gauges. Other measurements—leak testing, weight measurements, and visual quality checks—can be performed either online or offline. The company qualifies its test protocols using gauge R&R tests on its measuring instruments and MSA (measurement system analysis) studies of its lab technicians’ procedures.

A scientific approach to blow molding process development is another distinguishing characteristic of Metro Mold. It performs DOEs frequently. These can take weeks. Training is also a focus at Metro Mold. “We have 30 to 40 Paulson Training discs here for injection and blow molding and will send some blow molding people to Paulson seminars in the next year,” says Marquette. “We have also worked with a consultant to write training manuals.”

More than anything else, “Manufacturing the Impossible” requires the right people. “We are blessed with a lot of good people,” says Holland. “We’re surrounded by excellence.”

Related Content

Next-Generation Industrial Desktop 3D Scanner for QC

Exact Metrology’s newest version of Artec Micro boasts ultra-high precision.

Read MoreDual-Mode Portable Thickness Gauge for Packaging

Hand-held “pen” measures sheets, containers, panels, large parts with magnetic or capacitance mode; controlled by Bluetooth phone app.

Read MoreHow to Improve Quality with Offline Inspection and Analysis

Automated sample testing with a light table detects the smallest contamination in flakes, micro granulates and sample test sheets.

Read MoreAvient Receives PLASTICS’ 2023 Re|Focus Sustainability Innovation in Design Award

Said to be the first digital tool of its kind, the award was for Avient’s post-consumer recycled resin Color Prediction Service.

Read MoreRead Next

Troubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More