Chemical Purging: When and How to Do It Right

Extrusion blow molders are sometimes skeptical of chemical purging compounds (CPCs), and they have a point.

Extrusion blow molders are sometimes skeptical of chemical purging compounds (CPCs), and they have a point. All too frequently, these products have been oversold as a “magic bullet” for solving complicated processing problems. Used inappropriately or in a wasteful manner, CPCs invariably fall short, with the failure made worse by their substantial cost.

CPCs are best employed as one element in a broad strategy for coping with challenges commonly encountered in extrusion blow molding. One of these is dark-to-light color changes (e.g., blue to white), which often cause bottle streaking and flow-line discoloration. That in turn typically calls for time-consuming and frustrating machine tear-downs.

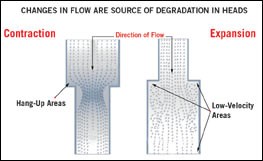

A second problem is degradation and consequent black-speck generation, often experienced with heat-sensitive materials like vinyl. Moreover, the build-up of carbon and color in complex ma chine components such as accumulator heads is exacerbated by the existence of “hang-up” and “negative-flow” areas in those parts (see diagram).

These challenges are usually addressed by tear-down of equipment (e.g., head disassembly) or use of a flushing resin or mechanical purging compound (MPC). MPCs can be as basic as a mineral-filled PE and are relatively low in cost. They are formulated to flow in ways that dislodge contaminants, and they carry abrasives to scour residue from affected part surfaces. MPCs are useful with commodity resins in monolayer structures when relatively basic processing equipment is involved. The same is true where vulnerable components are designed with relatively simple angles and flow paths.

However, extrusion blow molding is rather unforgiving when it comes to switching colors and materials and keeping degradation at bay during high-speed bottle manufacture. Workhorse bottle-grade HDPE and PVC require high melt strength, which makes them highly viscous and prone to surface build-up. Moreover, the nature of the process and the diverse shapes of hollow bottles result in complex machine flow-channel geometries. In this challenging environment, CPCs often provide a competitive advantage.

Dark-to-light changes

CPCs are specially formulated materials that generate gasses when subjected to heat and pressure. Consequently, they can penetrate deeply into inaccessible areas of machines and actually transform the contaminant’s molecular structure. When properly employed, CPCs are effective tools in the war on contaminants.

Potential paybacks from CPC use are considerable, as illustrated by a major blow molder of mono- and multi-layer pharmaceutical bottles. The firm uses HDPE and nylon and operates on a 24/7 basis. Despite careful production scheduling, this processor on average was required to conduct three dark-to-light color changes per week, each typically taking 6 hr. Based on a conservative estimate of machine downtime cost ($200/hr), these color changes cost 900 hr of downtime annually, worth $180,000. By adopting a CPC, this processor reduced average changeover time to 3 hr, realizing $75,000 in net savings (i.e., $90,000 less $15,000 in purging materials cost).

CPC use is best evaluated in terms of production cost and cost per purge rather than looking just at the cost of purging materials, which is typically $5 to $7/lb. A rough estimate of CPC required to purge an extrusion blow molding system is 1 to 1.5 times machine capacity—the amount of material needed to fill the machine from throat to head discharge. That’s just for standard extrusion blow equipment: It can take up to four times system capacity for an accumulator-head machine.

A first step in making dark-to-light color changes is to flush the bulk of existing material from the system using a natural material (regrind is fine) having at least equal viscosity to the original resin. After a brief flushing period, a nearly clear parison is generally produced. Any residue is limited to streaking (due to mandrel supports) or knit-line discoloration.

CPC use is most effective if temperatures in the machine area being cleaned are elevated during the heat soak. Temperatures of 480 to 550 F are optimal. With heat-sensitive resins like PVC, pre-purging is necessary to make sure residuals are fully removed before turning up the heat. The temperature at hang-up points should be boosted to intensify the activity of the CPC. If multiple heads are involved, it is advisable to raise the temperature of outboard heads 50° F higher than those for inboard heads.

It is also critical that purging material be kept fully contained within the zone being cleaned, since that too enhances CPC effectiveness. That means keeping the throat full and capping all vents. Two CPC purges of this nature are frequently needed to get optimal results.

Accumulator-head machinery poses particular challenges. These systems should be run on automatic while filling the entire system with CPC. The accumulator should cycle several times to ensure a complete fill. The temperature of the accumulator should be set about 10% above normal to help the CPC penetrate deeply into any contaminant.

Fighting degradation

Degradation tends to occur most frequently in areas where hang-up of resin or flow stagnation take place—such as in the parison head—subjecting small amounts of material to excessive heat history. When addressing degradation, prevention is better than cure.

Indeed, once a significant amount of carbon is deposited in hang-up or negative-flow areas, chances that a CPC alone can solve the problem are low. Best practice instead calls for viewing CPCs as a way to help avoid the onset or minimize the impact of degradation.

Failure to act early can be costly. In one case, a blow molder using a five-layer, four-head accumulator machine would have expended 16 worker hours to do a teardown. Instead, by purging at the first sign of contamination, he solved the problem in 2.5 hr using CPC costing $175.

Plants not running on a 24/7 basis are subject to another source of contamination. Blow molding plant shutdowns and start-ups typically expose materials left in the extruder to heat histories that can cause degradation. In such cases, we recommend using a CPC preventively at every shutdown. Even with 24/7 scheduling, periodic preventive CPC use is well-advised.

A common cause of problems related to CPC use is failure to follow suppliers’ recommended procedures closely. In most cases, these are time-proven and conservative, so cutting corners with respect to temperature settings, timing of steps, and amounts of CPC used should be avoided.

Related Content

Reversing Logistics for Plastic Film Recycling

Learn how Mainetti built a circular supply chain for clear film packaging.

Read MoreEvolving Opportunities for Ambitious Plastics Recycler

St. Joseph Plastics grew from a simple grinding operation and now pursues growing markets in recycled PP, food-grade recycled materials, and customized post-industrial and post-consumer compounds.

Read MoreCompatibilizers Aid Recycling & Upcycling of Mixed Resins

Compatibilizers are proving their worth in boosting critical properties such as impact/stiffness balance of PCR and PIR blends of polyolefins and other plastics.

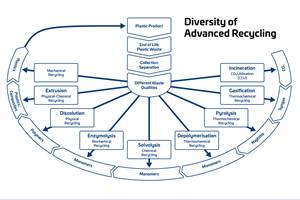

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreRead Next

Processor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read More.png;maxWidth=970;quality=90)