‘Easy-Molding’ Nylon Compound Targets Metal in Cars

Metal-replacement opportunities continue to emerge as fuel economies become more critical.

A recently developed nylon 66 with 50% glass fiber from Radici Plastics in Italy (U.S. office in Wadsworth, Ohio) is said to be easy to mold while offering new opportunities for metal replacement in automotive. Plastics represent about 15% of the total weight of an average-size car, a percentage that is expected to increase to 20% over the next 10 years, and Radici is pushing its new Radilon A RV500RW 339 NER as a material that will widen metal-replacement opportunities and allow molders to produce components that are not only lighter—and thus more environmentally friendly—but more complex, with multiple integrated functions.

BEEFED-UP PROPERTIES

Radici tested its new material against a competing 50% glass-filled nylon 66 and observed property improvements across the board, says Erici Spini, marketing and applications development manager. Measured at 74 F (23 C), tensile strength of the Radici grade reached 260 MPa (37,700 psi), a 12% increase over the other material tested. Strain at break was also about 12% better at higher temperatures (302 F/150 C). Tensile strength at weld lines was reported to be 20% higher than the competing 50%-glass compound.

Results of notched and un-notched Charpy impact test results showed that the Radilon A RV500RW 339 NER is up to 30% tougher than the other material tested. Other important characteristics of automotive structural materials are high-speed stress-strain properties. Radici’s tests show that the stiffness and energy absorption of the Radilon A compound are greater than for competing compounds at all load application speeds, Spini reports. These improved dynamic properties make this material particularly suitable for applications such as engine mounts and gearbox housings, he states.

The material is said to exhibit “significant improvements” in fatigue limits compared with competing grades, and a “noticeable advantage” in creep resistance, which is said to be critical for applications such as valve covers and oil cups, because these components are subjected to a constant load for their entire useful life, and maximum oil tightness is always required.

MOLDS WITH EASE

Production tests conducted by Radici revealed that the material processes almost exactly like the standard glass-filled nylon 66. Spini states that during development of this material, particular attention was paid to its mechanical properties when the material was exposed to high processing temperatures for prolonged hold times.

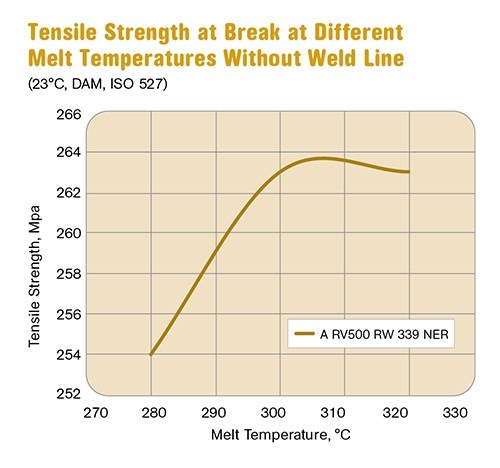

Radici’s intent was to bring to market a material that could be molded at temperatures above 570 F (300 C) in order to maximize weld-line strength without polymer degradation. Figures 1 and 2 indicate that the tensile strength of the material, with and without weld lines, does not change for melt temperatures of up to 590 F (310 C) and barrel hold times of up to 6 min.

Radici has already worked with Italian molder Sila Holding to develop one commercial application: a gear-shift cable reaction bracket that had been aluminium. The component is subjected to fatigue stress, vibration, and alternating loads at a temperature of about 250 F (120 C), with peaks of up to roughly 300 F (150C).

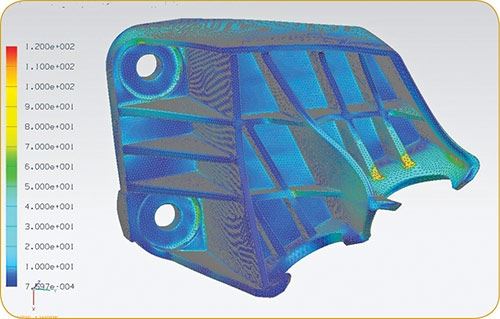

Following these tests, Radici and Sila, a primary supplier of gear shifts, worked together to completely redesign the part. The final model of the reaction bracket was developed through virtual model geometry optimization, using structural analysis.

The component in question has a maximum stress value of 120 MPa (17,400 psi) to ensure it will stand up even after moisture absorption. Spini says the switch from aluminum resulted in a part weighing 30% less and 20% less costly to produce.

Related Content

Scaling Up Sustainable Solutions for Fiber Reinforced Composite Materials

Oak Ridge National Laboratory's Sustainable Manufacturing Technologies Group helps industrial partners tackle the sustainability challenges presented by fiber-reinforced composite materials.

Read MorePrices for All Volume Resins Head Down at End of 2023

Flat-to-downward trajectory for at least this month.

Read MorePBT and PET Polyester: The Difference Crystallinity Makes

To properly understand the differences in performance between PET and PBT we need to compare apples to apples—the semi-crystalline forms of each polymer.

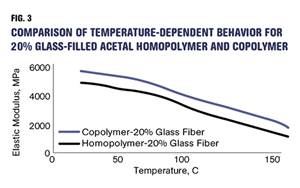

Read MoreHow Do You Like Your Acetal: Homopolymer or Copolymer?

Acetal materials have been a commercial option for more than 50 years.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More

.png;maxWidth=300;quality=90)