ELECTRIC DRIVES: Which One’s Right For Your Process?

Not all drives are created equal. There are a variety of options suited more to some applications than others. Here’s a handy guide to help you decide.

In today’s plastics processing machinery, the motive force powering the press can take several forms and technologies. Traditionally most machines were hydraulically driven, whereby a hydraulic pump driven by a fixed (constant-speed) electric motor powered most of the machines’ processes.

Over time, incremental improvements in efficiency, accuracy, and operating speeds were introduced. In the 1990s, a new technology became available for injection molding machines: The all-electric machine, which utilizes electric servo motors powering gears, racks, and ball screws to drive most of the machine functions.

The all-electric machines feature low noise, high-speed operation, and the freedom from certain issues associated with hydraulics, particularly those related to fluid handling and leaks within processing equipment. For all of the advantages of the all-electric machine, there are limitations, such as those associated with the machine’s capacity (tonnage) as well as increased maintenance requirements for physical components, due to wear on ball screws, belts, and gears.

NEWER DRIVE TECHNOLOGIES

Today, new technologies are available to drive large-tonnage injection machines, technologies that offer higher speeds, greatly improved energy efficiencies, and higher reliability. These new technologies build on existing motor-drive systems present in all machines and can be classified into three basic types:

1. Variable-frequency drives (VFD) utilizing V/f technology;

2. VFD drives using vector drive technology;

3. Electric servo drives

These more advanced drive technologies (such as servo drives) incorporate a variety of electronic control components and have a higher installed cost than a simple fixed-speed electric motor driving a hydraulic pump. As a processor, it is useful to evaluate the advantages—related to energy efficiency, operational flexibility, and overall system control and effectiveness—that can be achieved from use of these technologies.

Variable-frequency drives: Variable-frequency drives generate an output to drive a conventional AC induction motor. With V/f technology, the output can be varied in its frequency, which correspondingly varies the motor RPM. Due to the electrical characteristics of the motor, the output voltage is also varied in proportion to the frequency, thus the V/f designation. This relationship helps maintain the motor’s torque over its usable operating range.

These drives feature low relative cost but only provide motor speed accuracies of around 10% with varying loads. They have been used for many years to power extruders. Speed accuracy is more consistent with a steady load and can be improved over varying loads with the addition of a speed-measuring tachometer. However, dynamic performance (ability to respond and control pressure and velocity changes) is low and mainly suited to slowly changing processes. VFD drives using V/f technology have low-speed limitations and are only usable to about 400-500 RPM.

Vector drive technology: In the 1980s a new technology for VFDs emerged called vector drive technology. Utilizing microcontrollers, drive output could be manipulated to precisely control torque of a standard AC induction motor—even to zero RPM, when the motor is at standstill. This technology allowed servo-like control of the motor for a small additional cost.

The high inertia of an induction motor is the limiting factor of dynamic performance of the drive. Sensorless Vector VFDs offer tight speed accuracy, with lower limits at 200-300 RPM. Adding an encoder sensor to the electric motor allows the vector drive to operate as low as zero RPM and has the capability to electronically position the motor’s shaft to a high degree of accuracy.

While both types of VFDs are capable of a wide range of operation, there are certain technical design considerations. The driven induction motor must be rated for “inverter duty,” which provides internal shaft grounding. This prevents damage to the motor’s bearings from electrical currents induced in the shaft and frame of the motor by the high-frequency currents in the VFD.

In addition, operation at low speeds and high torque can result in destructive heating of the motor unless auxiliary air or water cooling of the motor is present. Limitations of high speeds also exist, generally limiting the maximum speed to two and a half to three times the motor’s rated RPM.

Servo drive technology: Electric servo motors are permanent-magnet AC motors that are designed for a minimal inertia and have peak torque that is two to three times higher than steady-state torque, so highly dynamic speed changes are possible. A high speed range, maximum torque available at zero RPM, and very high dynamics are the hallmark of servo motors.

This technology does require more complex drive electronics; however, this is offset by the ability to precisely control speed, torque, and position of the servo motor. Like VFD driven motors, low- or zero-speed operation combined with high torque may require additional air or water cooling. Servo motors are limited in horsepower compared with AC induction motors, so the application of multiple servo motors may be needed for higher power requirements.

DRIVE SELECTION FOR DIFFERENT APPLICATIONS

Both simple VFDs and Vector VFDs are well established in extrusion. Servo motors are also the standard in all-electric injection molding machines. Hydraulic machines, comprising the vast majority of molding machines, are increasingly adopting these drive technologies to power their hydraulic systems.

Injection machines using fixed-speed electric motors progressed from simple hydraulic drives, using a fixed-displacement pump, to the more modern and efficient variable-displacement pump. Variable-displacement pumps can be more energy efficient; however, it is possible that when servo and proportional valves are used to provide a high degree of precision in pressure and flow control, energy losses can still be significant.

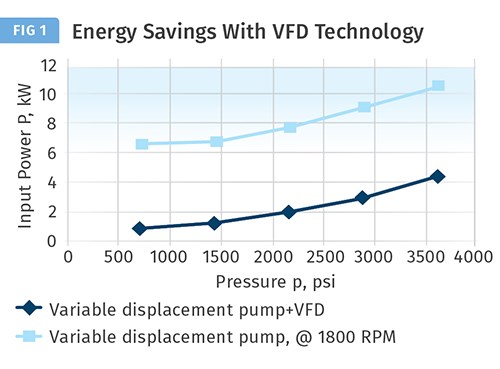

An emerging and more efficient approach is to utilize variable-speed motors and drives to accurately and dynamically control pump speed. By modulating pump RPM, precise control of pressure and flow can be attained.

Servo-motor driven pumps can match the performance of all but the top tier of servo-valve controlled machines. Pressure and flow control response in the range 10 miliseconds is easily achieved, resulting in high accuracy and high dynamic response.

By directly controlling the flow and pressure via the pump, energy losses are minimized, resulting in 10-40% savings in power. It should be noted that molding machines incorporating servo drives and specialized pumps are more expensive than conventional hydraulic machines, but are significantly less pricey than equivalent all-electric machines.

Presses with lower performance requirements can use lower-cost VFD vector drives with pumps suited for the wide range of RPM operation. This drive technology also has the potential to save energy, but there are limits on the drive dynamics. Since a large-inertia induction motor is generally used, acceleration and deceleration rates are limited.

Slower-reacting machines and products that require less precision may be suitable for VFD vector drive technology. Pressure control also becomes slower and less precise due to the limits of the drive dynamics and may require additional loss-generating hydraulic components to improve pressure-control accuracy.

VFD DRIVES WITH ‘INTELLIGENT’ HYDRAULIC PUMPS

In order to improve machine performance when using VFD drives, the addition of an “intelligent” hydraulic pump can reduce the negative characteristics of the motor drive dynamics. One product is an “intelligent” piston pump that interfaces directly with the VFD electronics.

This technology allows electronic control of the pump’s flow and pressure by varying the mechanical displacement of an axial piston hydraulic pump that is optimized for variable-speed operations.

For steady-state operation, the pump will command the VFD drive speed to match the needed requirements. For dynamic operation the fast-reacting pump-displacement control performs the speed and/or pressure changes, while the relatively slow-reacting drive “catches up” to the requirement. This combination offers system response times in tens of milliseconds, even while the drive acceleration times are in the hundreds of milliseconds.

One advantage of this technology is that it can be applied to machine rebuild and retrofits for service-life extension, achieving targeted efficiency improvements that would otherwise require replacement with servo-driven machines. While costs include a VFD, potential motor replacement, and specialized pump and control modifications, it can be a cost-effective solution for machine upgrades, with favorable investment returns.

OTHER APPLICATIONS

Any machine that requires fast, precise motions that may have overlapping cycles can benefit from modern drive technologies. One example is a blow molding machine. Parison and mold motions often overlap and must be precisely controlled at high speeds. Hydraulic systems often utilize fluid-storage accumulators to supply large flows, while a pump supplies average demand.

These and other “hydraulic accumulator”-based systems can use the newer drive technologies to save energy. For example, using a VFD to drive a hydraulic pump, the motor’s drive speed can be varied to match the average flow demand of a machine. Lowering the pump speed to match flow demand and minimizing RPM during idle periods can reduce electrical energy demand and noise.

ELECTRICAL CONSIDERATIONS

All of the drive technologies discussed here can generate varying degrees of electrical interference in a plant’s power grid. Known as harmonic distortion, the generation of high-frequency, high-current, and high-voltage signals can cause undesirable effects on a plant’s power system. Effects range from electronic disturbance to failure of electrical devices. These issues should be considered when selecting supplier equipment and become more critical in plants using these technologies to retrofit or rebuild existing machines, as well plants that are adding more machines using this technology.

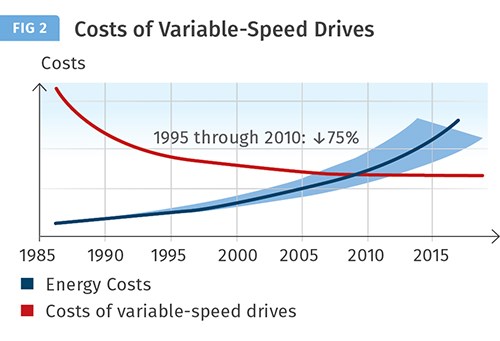

NEWER DRIVE TECHNOLOGY OFFERS LONG-TERM SAVINGS

These drive technologies generate savings on power usage that can be attractive in many applications. The cost of drive technology needs to be weighed against the expected energy savings. Utility incentives and high utility costs (many times based on geographic factors) favor these changes in drive technology. These technologies have become dominant in the new injection machine market. The advantages of energy savings plus high-performance operation rival all-electric machines and are applicable up to the largest machine size.

While there is additional cost, return on investment and total cost of ownership make a strong case for assessing these technologies, in both new machines and retrofit/upgrade applications. Processors can benefit from the advantages of reduced energy consumption and low noise while enjoying improved machine performance.

Related Content

Slimmer All-Electric Press Debuts

A slimmed-down version of Engel’s all-electric, e-mac injection molding machine is among eight displays, which also include LSR micromolding, quick mold changes and a cube mold.

Read MoreCompact Hybrid Injection Molding Machine Launched

Sumitomo Heavy Industries Ltd. (SHI) has introduced the iM18E, promising the smallest footprint in 20-ton machines.

Read MoreInjection Compression Molding as Alternative to Thermoforming

Arburg will show its all-electric Allrounder 720 A press utilizing injection compression molding to create thin-wall IML cups from PP.

Read More50 Years...600 Issues...and Still Counting

Matt Naitove marks his first half-century in plastics reporting, with a few of his favorite headlines.

Read MoreRead Next

Processor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read More