News

Polyfuze Graphics Corp. Partners With RFID Specialists

To help customers navigate the complexities of RFID technology, Polyfuze has partnered with such companies as HID Global.

Read MoreBrightmark Intends to Build Recycling Circularity Center in Upson County, Georgia

The company announced plans for an investment totaling $950 million.

Read MoreExxonMobil Collaborated on Creation of a High-Performance, Recyclable, Nonlaminated Freezer Film

The company partnered with provider of plant-based foods Bunduelle and film extruder Constantia Drukpol.

Read MoreCoca-Cola’s Redesign of Small PET Bottles Pushes Lightweighting Below Prior ‘Floor’

Coca-Cola thought it had reached the limits of lightweighting for its small PET carbonated soft drink bottles. But a “complete redesign” led to a further 12% reduction.

Read MoreDelrin Partners with Entec and Channel Prime Alliance

Through this partnership, Entec and Channel Price Alliance will distribute all grades of Delrin acetal to customers in the U.S., Canada and Mexico.

Read MoreBorealis Completes Acquisition of Integra Plastics AD, Expanding Recycling Capacity

Integra plastics uses optical sorting to capture value in postconsumer waste polyolefins.

Read MoreFormerra Partners With Evonik for Expansion of High-Performance Nylons

The company will distribute several of Evonik’s Vestamid materials in the U.S., Canada and Puerto Rico.

Read MoreTeknor Apex and UBQ Materials to Further Expand Development of Sustainable Materials

Their strengthened compounding partnership will expedite product development.

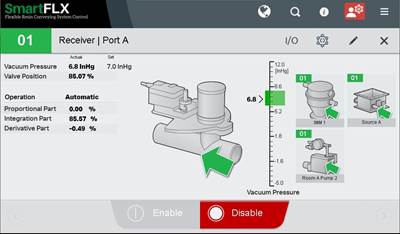

Read MoreConair: Going All In on AI

A dozen new products debut at NPE, but the company says new AI-based conveying technology is the true game changer.

Read MoreiNOEX Celebrates Forty Years of Intelligent Measurement and Control Solutions at NPE2024

iNOEX’s expanded product portfolio highlights the importance of automated technology for the plastics extrusion industry.

Watch