Injection Molding at K 2013: Doing More with Less

K 2013 Show Report

More productivity with less energy consumption and capital investment; more operations in the machine or manufacturing cell with less time, labor, energy, and capital—these were the common themes of injection molding exhibits at October’s K 2013 show.

More productivity with less energy consumption and capital investment; more operations in the machine or manufacturing cell with less time, labor, energy, and capital—these were the common themes of injection molding exhibits at October’s K 2013 show in Dusseldorf, Germany. One article cannot cover the vast range of news at the show. This post-show report focuses mainly on news of interest to North American molders and on primary molding equipment. Robots, hot runners, and tooling will be covered in separate reports. And for a full picture of the news, refer also to our September show preview and December initial news report for developments that aren’t repeated here.

SCORES OF NEW MACHINES

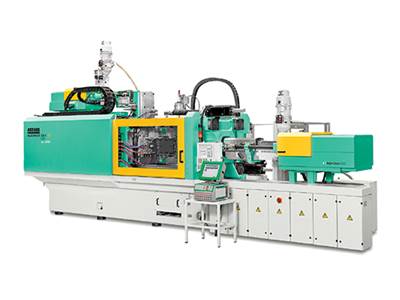

All-electric, hybrid, hydraulic, and servo-hydraulic: Machines of every size and stripe made their debuts from suppliers across the globe. In September, we previewed many of these new entries from firms such as Arburg, Athena Automation, Boy Machines, Engel, Haitian, KraussMaffei, MHS, Negri Bossi, Netstal, Sumitomo Demag, and Wittmann Battenfeld.

Here’s what new information popped up at the show:

•Arburg’s new machine is the Allrounder 820A (400 metric tons), which was shown with the new 2100 size injection unit. The latter increases the shot capacity to 1286 g of PS. (U.S. office in Newington, Conn.).

•A new name for many North American molders is Borche Machinery Co. (also spelled Borch) from China, with offices and spare-parts inventory in Ontario, Calif., and Hamilton, Ont. Borche also exhibited at NPE 2012. The company’s newest products are the BS-III Servo Series of toggle presses (60 to 1800 m.t.) and BU Ultra-Max Series of two-platen machines (500 to 6000 m.t.). Both have energy-saving servo pumps. Borche also offers BT Series hydraulic toggles (60 to 1800 m.t.).

•Boy Machines (U.S. office in Exton, Pa.) brought out five new machines that come standard with energy-saving servo pump and EconPlast plasticating unit . One model was reported in September—the Boy 25 E (also available in a vertical-clamp version, 25 E VH) with 25 m.t. clamp. It offers three new injection units with “differential injection” capability. This refers to the flexibility to select either fast injection for thin-wall parts or very high injection pressure for hard-to-fill shapes. Other new models are the Boy 50 E, 60 E, 80 E, and 100 E (50, 60, 80, and 100 m.t.). The 100 E is a new, larger size for the company (the 90 E was previously the biggest). Boy has discontinued the 22, 55, and 90 models. All the new models also will have as standard the new Alpha 2 control with large touchscreen that accepts gestures for functions such as scrolling between screens.

Boy’s new EconPlast system (econplast.de) is a patented technology that addresses the fact that the injection barrel is the biggest energy consumer on the machine. Boy claims can it can cut energy consumption by 40% for barrel heating and 60% for plasticating. The system achieves more efficient heating by embedding the heater bands in grooves in the barrel and covering the entire barrel with insulation. Boy also claims faster heat-up times and more precise temperature control, as well as improved cooling of feed zones with much less energy loss. EconPlast is available for all barrels of 24 mm diam. or larger.

Boy also introduced a free smartphone and tablet app for iOS or Android devices. It includes calculators for cooling times and clamp-force requirements, as well as data sheets for processing, drying, and density of common plastics. It also provides quick access to Boy sales, service, and process engineering personnel.

•Fu Chun Shin Machinery (FCS) of Taiwan, represented here by Maruka U.S.A. Inc., Pine Brook, N.J. (marukausa.com) introduced the SD series of servohydraulic toggle presses. These are the former HT Series with a redesigned exterior shape for a sleeker look. The first model is the SD-150 (150 tons), and future models will range from 30 to 1420 tons.

•Negri Bossi (U.S. office in New Castle, Del.) showed off its new “Evolution” program of redesigns and upgrades for several of its press lines, signified by a small “e” added to the name. New eCanbio hydraulic toggle presses have prismatic linear bearings on the moving platen, eliminating tiebar bushings. This is said to result in faster movements and more accurate mold alignment. Platens have also been engineered to reduce mass, and tiebar spacing has been enlarged on all Canbio presses. It’s available in a “FAST” version with accumulator and SmartEnergy variable-volume pump with variable-speed inverter drive. The latter is said to use only 10% more energy than an all-electric machine.

Also new is the eVector series (650 to 1500 m.t.) with redesigned toggle clamp, wider tiebar spacing, longer stroke, and optional SmartEnergy pump. A wide-platen 1000-ton version has around 64 in. between tiebars.

New eVesta all-electric models have linear bearings like the Canbio Evolution models, so there’s no grease on the tiebars. Beefed-up servo motors are said to boost clamp speeds by 30%.

In addition, there’s a new smaller size of Bi-Power hybrid two-platen press; this 1000-m.t. model is now the lower end of the range, which previously spanned 1300 to 7000 m.t. Servo pump and electric screw drive are standard.

The Janus hybrid range (servo pump plus electric drive on screw and clamp traverse) has been upgraded with faster clamp motion since NPE 2012.

•As we reported in September, Netstal (U.S. office in Florence, Ky.) presented three new machines at the show, the all-electric Elion 2200 (220 m.t.), Elion 4200 hybrid with servo pump (420 m.t.), and Evos 4500 hybrid with servo pump (450 m.t.). At the show, Netstal previewed its plans for 2014:

—Rework the all-electric Elion 1750 and 1200 to modular construction.

—Develop new 250 and 870 electric injection units.

—Add multi-component injection capability to Elion series.

—Expand availability of the new aXos control in the Evos and Elion lines.

•Victor-Taichung of Taiwan, represented here by Fortune International, Somerset, N.J., has upgraded its all-electric Va II series (50 to 200 tons) in the past year with wide platens, redesigned toggle system, more robust clamp and injection units, low-friction linear guides on the injection unit, and the VPC2100 controller with a larger and higher-resolution touchscreen, graphical user interface, and optional remote monitoring.

COMPOSITES: A NEW FRONTIER

One area of injection molding that is seeing a burst of new creativity is the field of structural composites. Still in its infancy, it is capturing imaginations—and commercial applications—in the automotive field, primarily, but also potentially in computers and electronics. Up to now, there have been two main players in machinery, but the ranks are growing.

Engel (U.S. office in York, Pa.) put on, or participated in, four demonstrations of different approaches to injection molding structural composites from oriented continuous fibers. As noted in our September preview, two of them involved thermoplastic composites and two of them thermosets. Both an automotive brake pedal and a case for a tablet PC were produced by overmolding or backmolding continuous-fiber thermoplastic prepreg sheets with additional thermoplastic. These are the first projects of Engel’s new technology center for lightweight composites in St. Valentin, Austria, which employs 15 people.

The brake pedal was produced in cooperation with ZF-Friedrichshafen, which won an award a couple of years ago for the first thermoplastic composite brake pedal. That earlier design was produced in two steps—preforming and then overmolding the nylon prepreg sheet. The new version of the brake pedal at K 2013 was significant both for its more complex 3D shape and for its one-step process. The composite prepregs were heated and simultaneously preformed and overmolded in an Engel insert 200 vertical press with the aid of a six-axis robot and infrared oven with a shuttle system. The molded part required no trimming.

Of Engel’s two thermoset composite demonstrations, one involved high-pressure resin-transfer molding (HP-RTM) of a latch cover for a KTM’s X-Bow sports car. Dry carbon and glass fabrics were impregnated with liquid two-component PUR in a new large vertical two-platen press, v-duo 700 (700 m.t.), which was developed specifically for composites. It is about 60% lighter in weight and 50% shorter in height than conventional presses. Platen parallelism control during molding is standard, as is energy-saving servo-hydraulic ecodrive. The clamp is accessible from all four sides for easier maintenance and simpler automation.

The fourth molding demonstration was exhibited by the Institute of Plastics Processing (IKV) at RWTH Aachen University in Aachen, Germany. It used dry glass fabrics impregnated with molten caprolactam monomer for in-situ polymerization to nylon 6. Six layers of fabric with binder were preformed with heat and vacuum in a tool with hot/cold cycling, then cut to shape. “Due to the extremely low viscosity of the monomer, even the finest fiber filaments can be infiltrated without damage, and therefore tailored fiber structures can be integrated to improve mechanical properties,” said Peter Egger, head of Engel’s composite technology center. The fabrics were injected and cured in one Engel tiebarless press (e-victory 120) and then the parts—soccer shin pads in two cavities—were transferred by robot to a second tiebarless press (victory 80) for overmolding with TPE. The same linear robot loaded the glass preforms in the first mold, transferred cured parts to the second press, and demolded the finished parts.

Since the first stage of the process clamped onto the glass fabric, leaving dry fibers along the edges, these were encapsulated by TPE in the final step. Total cycle was 6 min, though IKV sources said it could be cut to 3.5 min, depending on ambient humidity, which affects the nylon polymerization.

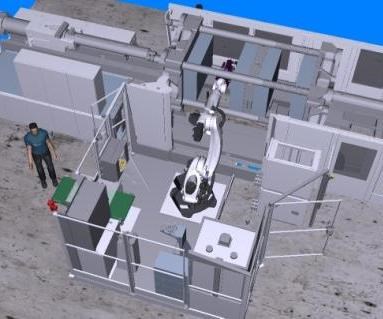

KraussMaffei (U.S. office in Florence, Ky.) demonstrated an expanding range of capabilities in continuous-fiber composite overmolding with a complex application using fabric-based organic sheet, unidirectional tape, and a hollow section. The automated molding cell was based on a CX 300 (300 m.t.) two-platen press with a six-axis robot mounted on the fixed platen. The overall shape of the part was a square, hollow channel with a flat cover. The process involved preheating two sheets of nylon 6/glass-fabric sheet in a hot-air convection oven, which KM said provides more uniform heating than radiant infrared. In one mold cavity, one sheet was formed into a long U-channel shape and overmolded with ribs in glass-filled nylon. Overmolding also filled out the outer contours of the part to produce a net shape that needed no trimming. In addition, fiber-spreading devices created functional holes in the part.

While all this was occurring, the second organic sheet was preheated and bonded to piece of unidirectional nylon/glass tape applied for local reinforcement. Then this flat sheet (the “cover” for the channel) was placed in the second mold cavity, to which the first overmolded part had been transferred by the robot, and the two were joined under pressure while additional melt was injected along the seams. Two more holes were needle-punched into the part, and inert gas was injected into the hollow channel shape to prevent wrinkling and provide a smooth, flat surface. The robot had two different grippers to accomplish all these tasks. The overall cycle was 57 sec.

At this show, Arburg made its debut in the composites field. A servohydraulic Allrounder 820 S (400 m.t.) combined organic sheet composite molding with DLFT (direct long-fiber thermoplastic) technology in molding a part similar to an automotive brake pedal. Two pieces of “organosheet” of glass fabric and PP copolymer were preheated at a two-sided infrared bank and placed robotically in the mold, where they were held in place by pins that pushed the fibers aside, rather than breaking them, when the mold closed. The sheet was formed into a 3D shape in the mold and overmolded with long-glass PP. Continuous glass rovings were fed directly into the injection barrel after the melting zone. The glass was chopped by the screw—in lengths continuously variable up to 50 mm—but fiber attrition was said to be minimized by feeding into already melted polymer. An extra-long 33:1 L/D screw was used.

This approach reportedly is simpler and more economical than mounting a twin-screw compounding extruder over the injection barrel, as has been offered by KraussMaffei and others. The 202 g part was molded in a single cavity with a 40-sec cycle time. The two pieces of organosheet—of different thicknesses—were bonded by the overmolded compound, which also sealed the edges of the sheet, producing a net-shape part that needed no trimming. The Krelus Infrared heaters from Switzerland turned on and off for each cycle to save energy.

Arburg will undoubtedly not be the last machine builder to tap into the composites action. Officials at Wittmann Battenfeld (U.S. office in Torrington, Conn.) said at the show that the company is looking hard at composites molding. In their view, the process requires less in the way of new injection molding technology than of adapting specialized automation—an area in which Wittmann feels it is well qualified.

Meanwhile, Kistler of Switzerland (U.S. office in Amherst, N.Y.) has new sensors for liquid reactive molding processes such as HP-RTM or in-situ polymerization. These membrane sensors measure both vacuum and filling pressure in the tool. Kistler is also at the prototype stage with sensor systems for measuring both the pressure in the mold for forming heated composite sheet and the injection overmolding cavity pressure.

MULTI-COMPONENT MOLDING

One of the most frequently demonstrated technologies at the show was multi-material or multi-color molding, either using overmolding or in-mold assembly, or both. Almost all major suppliers showed something in this vein (see September preview).

One of the more elaborate examples was a cap molding demonstration—one of three—by Ferromatik Milacron (U.S. office in Batavia, Ohio). The cell used an F 270 all-electric machine with a second injector mounted at an angle on the moving platen. A turning-stack cube mold with two parting lines produced two-piece twist-top caps from two colors of PP with in-mold assembly. The mold from Foboha (U.S. office in Beverly, Mass.) had two parting lines, each with 8+8 cavities. After each 90° mold rotation, automation on both sides of the machine unscrewed one closure component and then screwed it onto the other part; then the assembly was ejected at the same station. Cycle time was 9.5 sec.

As reported in December, Kortec, Rowley, Mass., introduced three-layer coinjection technology for making UV-barrier PET preforms for milk bottles. Kortec’s special nozzles produce preforms with white layers inside and out and a black light-barrier layer in the middle.

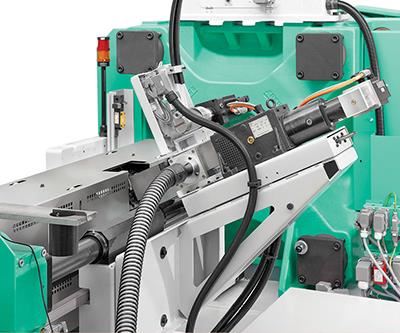

Since not everyone wants to buy a dedicated multi-component machine, add-on injection units offer a flexible and cost-effective way to convert standard machines when needed for a multi-shot job. Mold-Masters Ltd., Georgetown, Ont., which claims to be the largest supplier of auxiliary injection units, showed its expanded E-Multi line of electric units. New models are the EM4 (largest) and EM2 (second-smallest), for a total of 12 models with shot capacities from 7.7 to 500 cc. They have a new controller with a large touchscreen and high-end capabilities. In addition to floor and mold mounting, there’s a new platen-mount option with transverse and radial movements to allow the injector to swing out of the way for mold changes.

Otto Männer GmbH of Germany (U.S. office in Lawrenceville, Ga.;) showed off new compact, highly precise electric injection units adapted from its unusual micromolding system (see below). Called duo-män, these add-on injectors come in shot capacities from 0.42 to 31.92 g of PS. One of these was shown in use at the booth of Fanuc (represented here by Milacron), where it was integrated with Fanuc’s Roboshot all-electric press.

Another add-on micro-injector is now available from Rambaldi & Co. of Italy, represented here by ALBA Enterprises, Rancho Cucamonga, Calif. (albaent.com). The Babyplast 1/10P hydraulic injector is adapted from the micro-machine of the same name. It has a color touchscreen display, wheeled cart containing the hydraulics and electronics, shot sizes from 3 to 36 cc, and injection pressures up to 2030 bar on the smallest unit. The control stores over 100 tool settings and a record of the last 20 cycles.

In addition, the full benchtop Babyplast injection machine now is available with an electric turntable for two-shot molding.

Boy Machines showed off its portable auxiliary injector, which was introduced at NPE 2012.

And MGS Mfg. Group, Germantown, Wis., displayed its latest Universal Multishot (UMS) portable, servo-electric auxiliary injection unit. It boasts significantly improved repeatability and accuracy, and well as high nozzle touch force of up to 36,000 psi to prevent leaks. It uses no springs or belts to engage the nozzle. It's available in a mold-mounted version or on a portable cart together with hydraulics to power core pulls and vacuum controls for venting.

In addition, MGS showed a new version of its servo-driven UMS rotary platen, which has been made significantly thinner. It's now 5.9 in., down from 7.1 in., while being simultaneously more robust in its indexing mechanism, which uses cam followers.

A novel method of multicolor molding with one injection barrel was introduced by Sumitomo (SHI) Demag (U.S. office in Strongsville, Ohio). Its novel activeColorChange system was set up to feed three liquid colors to the machine barrel downstream of the melting zone. After a preset number of shots, the system switched colors.

At the show, it took about 30 shots to change from white to blue and 33 shots from blue to silver. The system uses colorant containers pressurized to 10 bar and dispensing modules with servo screw pumps on the barrel, capable of injecting liquids at up to 150 bar. Both components come from ViscoTec in Germany (U.S. office in Kennesaw, Ga.). This approach can use any commercial liquid colorant or additive. Because the color is dispensed after the melting zone, the colorant experiences less heat history and less of the screw and barrel require cleanout for color changes.

LSR MOLDING

Though it requires specialized equipment and experience, liquid silicone rubber (LSR) or liquid injection molding (LIM) continues to attract molders’ interest. Among the numerous LSR exhibits at the show, Elmet Elastomere of Austria (U.S. office in Lansing, Mich.) showed off a micro-sealing part for wires in a medical device. It was only 1.6-mm long, and 0.1-mm thick, with0.3-mm ID. It had been molded in two cavities on a Wittmann Battenfeld MicroPower machine.

As reported in December, Elmet has explored new ways to utilize low-temperature UV-curing LSR formulations from Momentive Performance Materials, Waterford, N.Y. Elmet has built molds with polycarbonate inserts as a clear “window” through with to shine UV light to cure the part, but the plastic insert wears out after 5000 to 10,000 shots. Elmet’s newest solution, in the case of thermoplastic/thermoset overmolding, is to use the clear thermoplastic first shot as the window for UV light to reach the LSR in the second shot.

Elmet showed off recent upgrades to its TOP 3000 LSR metering systems. It has a new controller with a USB port, touchscreen, and WiFi connection (via a free app). The latter is said to be useful for clean rooms—it allows the dosing equipment to be located outside the clean room but it can be monitored and controlled from inside. For example, operators inside the clean room can see how much material is left and how long it will last at the current production rate.

Yudo of Korea (U.S. office in Plains City, Ohio), known here primarily for its hot-runner systems, has come out with an LSR mixing/metering system. It’s enclosed in a box that measures 1070 x 1270 mm x 1730 mm high and has a side door and a 10-in. touchscreen on the front. It dispenses up to 3.3 lb/min at up to 250 bar pressure and a 1:1 ratio. Yudo also offers cold-runner systems for LSR molds.

Priamus (U.S. office in Brunswick, Ohio) has adapted its FillControl system for automatic hot-runner balancing with the ability to balance multicavity filling of LSR in cold-runner systems. The solution is again the automatic detection of the flow front via cavity pressure or temperature sensors and the automatic delay of the valve-gate opening to achieve equal filling. Essential to control of very low-viscosity LSR are use of pressure sensors with twin seals and new control software that can measure less than 1 bar pressure change in the mold.

MICROMOLDING IS BIG

As noted above, micromolding and LSR sometimes overlap. The Babyplast desktop micromolding machine (see above) now can mold standard two-component LSR, rather than just premixed cartridges as before. It also boasts upgraded controls with pressure switchover capability, increased mold area (75 x 75 mm), energy-saving electric inverter drive for the hydraulic pump, and a new parts picker controlled by the machine.

As reported in September, Wittmann Battenfeld demonstrated a novel setup using two of its 5-ton, all-electric MicroPower micromolding systems, linked by an enclosed conveyor in a cell for clean-room two-shot molding and assembly of diagnostic “lab-on-a-chip” devices.

Two unique new micromolding systems were in operation at K. Both are developments from companies known mainly for hot-runner systems. One is the 4-ton, all-electric M3 machine from MHS-Mold Hotrunner Solutions, Georgetown, Ont.

The other is a new two-shot version of Otto Männer’s micro-män micromolder. This unique, all-electric system is a complete production cell with molds that travel on a track around the periphery from injection to cooling, ejection, sorting, and quality-check stations. In the twin-injector version, the mold is filled at one injection station and shuttles to the second injector for overmolding before continuing on its way to other stations. One- and two-component systems are available with 5- and 15-m.t. clamps and two-stage screw/plunger injectors with shot capacities of 0.42 to 9.03 g of PS and pressure capability up to 3000 bar.

FOAM & HOLLOW MOLDING

Both KraussMaffei and Wittmann Battenfeld demonstrated ability to produce foamed parts with very smooth, glossy surfaces using Variotherm hot/cold mold-temperature cycling. KM molded a 127 g washing-machine cover of ASA/PC in an all-electric AX 130 press equipped for the MuCell microcellular process of Trexel Inc., Wilmington, Mass. Dynamic mold-temperature control was provided by the machine’s MC6 controller, which regulated a TCU from gwk of Germany. The latter uses a hot-water reservoir that allows quick change from hot to cold water circulating in the mold. The polished mold surface and placement of water lines as close as possible to the mold cavity contributed to the highly aesthetic result. Cycle time was 37 sec.

Wittmann Battenfeld used its own Cellmould gas-injection process and variotherm molding with the aid of the BFMold (ball-filled mold) technology. The latter sends water through a mold chamber filled with ball bearings to ensure uniform flow across the mold and quick temperature transitions. After demolding, the flat ABS parts were exposed to ionized gas to burn off silicone-oil mold release and then pad printed.

Especially interesting about this cell was the use of a vision sensor to evaluate the parts’ surface gloss and smoothness with new software being developed by the Polymer Competence Center Leoben (PCCL) in Austria. As explained by PCCL senior researcher Dieter Gruber, PCCL is attempting to overcome previous limitations in gloss and surface-finish measurement, with closer correspondence to human vision. With conventional measuring instruments, he said, human observers may see little or no difference between measured gloss differences or may perceive a proportionally greater difference between two relatively close gloss values. “We attempt to measure the visibility of defects,” Gruber said, “not physical topography of the part, but what you can actually see.” The technology works for smooth and curved surfaces and is intended to become ready for market in the next few years.

Meanwhile, Trexel announced that use of its MuCell physical foaming process has become much simpler and less expensive, thanks to the new T-Series of SCF (Super Critical Fluid) dosing and delivery systems. The system converts gaseous carbon dioxide or nitrogen into a supercritical fluid and injects precise doses through a port in the injection barrel. The new design is simpler and more compact, with no more bulky block on top of the molding machine.

The new touchscreen with process animation helps make control much simpler and easier. The user need enter only the shot weight and gas percentage desired. It displays gas level and pressure in storage tanks, as well as historical data curves and logs. Energy consumption reportedly has been cut in half, reducing operating costs. The equipment itself is also a little less expensive.

Four sizes of the T-Series are available, including one for small screws (<40 mm diam.) and small shots (10 to 120 g), a size range in which MuCell systems have not been cost-competitive before, according to Trexel. The smallest units are even less expensive and simple in design than other models.

As reported last month, Trexel also announced at the show a new way to achieve lower density parts without sacrificing properties by combining MuCell with hollow glass microspheres from 3M.

Japan Steel Works (JSW, with U.S. office in Lake Zurich, Ill.) exhibited a new enhancement to its Die Slide molding process for making hollow parts by molding two halves in separate cavities of the same mold, and then bringing them together via a sliding plate and overmolding the seam between them to provide a seal. The new wrinkle is integrating a hot-plate heater to soften the mating surfaces to be joined, for a better seal.

CONTROLS & COMPONENTS

On several new presses, Engel showed off its new CC 300 control. It can operate in conventional “component view,” showing functions and parameters related to injection, clamping, ejection, etc.; or else in new “task view,” showing information related to mold change, maintenance, startup, etc. Another new feature is the “e-move button,” the central operating element, which provides millimeter-precise accuracy and speed-sensitive control of all machine and robot movements. Pressing that one button starts the machine and initiates various motion sequences. The 21-in. HD touchscreen recognizes gestures—screens can be changed with a swipe, for example. Also, the operator interface panel can be set to swivel to different positions according to the preferences of different operators. The control recognizes an operator’s login and moves to the desired position automatically, and then retracts flat against the machine on logout. The CC 300 runs all CC 200 programs.

Sumitomo Demag demonstrated its activeFlow Balance or Flow Front Control technology on its all-electric InteElect machine (it’s also available on the electric SE-EV series). This technology is designed to provide uniform filling of multiple cavities or single parts with hard-to-fill areas. It was demonstrated on a family mold at K. The system allows the material to decompress as it fills the cavities by halting the screw momentarily (around 0.3 sec) at the transfer point. Controlled deceleration and stop time prevent any screw bounce in the electric injection unit. After the pause, injection is completed, perhaps at a lower pressure and with reduced clamp tonnage to facilitate venting and minimize molded-in stresses.

A new cavity-pressure sensor from Kistler was previewed in September. Priamus also showed new sensors. These “heavy-duty” temperature sensors can be used at mold temperatures up to 320 C (608 F) for LSR and other thermosets, as well as high-temperature engineering thermoplastics. These sensors can be ordered with a hardened front for abrasive materials like powdered metal or ceramic compounds.

Priamus also has a new BlueLine voltage module for measuring injection analog machine signals in the control cabinet and converting them to digital signals for the company’s BlueLine digital control devices.

Also new from Priamus is the Priafit mounting sleeve for mold sensors. It combines the mounting nut and distance sleeve to make sensor mounting easier and less expensive.

Given the increasing popularity of servo-driven hydraulic pumps for saving energy, Siemens Motion Control Business, Atlanta, introduced a new Sinamics servo pump for use on hydraulic presses. It combines a Sinamics S120 servo drive and a fixed-capacity pump. It’s said to be quieter than a variable-volume pump and easy to integrate into a molding machine. Sizes are from 7.5 to 90 kW. No additional PLC is required.

Tecnomagnete of Italy (U.S. office in Sterling Heights, Mich.) has increased the durability of its magnetic quick mold-clamping systems and has added the ability for the magnetic mounting plates to self-clamp magnetically to the machine platens with no mounting screws.

Zeiger Industries, Canton, Ohio, offers new modifications of plasticating units for sensitive materials—halogen-free flame-retardant compounds, clear polycarbonate, and high-flow rigid PVC for technical parts. Modified components include the continuous-taper end cap, nozzle, nozzle tip, screw design, and screw tip. Screws can utilize stainless-steel powder-metallurgy materials and longer tips for less shear.

Related Content

Compact Hybrid Injection Molding Machine Launched

Sumitomo Heavy Industries Ltd. (SHI) has introduced the iM18E, promising the smallest footprint in 20-ton machines.

Read MoreCustom Injection Molder Plugs into All Electric Machines

Formerly a showroom for early-aughts-era Van Dorn hydraulics, the newest additions to Drummond Industries’ transforming fleet are all-electric Niigata injection molding machines.

Read MoreNew Hybrid, All-Electric and Vertical Injection Molding Machines

NPE2024: In addition to new machines, LS Mtron will also launch a new 18-inch multitouch controller from Keba.

Read MoreWord Games: What’s a ‘Hybrid’?

Any molder will tell you there’s a difference in working with electric vs. hydraulic drives. Servohydraulic is still hydraulic; a hybrid machine is something different. Imprecise use of terms causes needless confusion.

Read MoreRead Next

Arburg Grabs Spotlight at K 2013

WEB EXCLUSIVE: At K 2013, injection machine builder introduces the Freeformer, a novel machine for additive manufacturing.. But there was plenty to see in hot runners, LSR processing, and lightweighting as well.

Read MoreK 2013 Preview: Injection Molding

Next month’s mammoth triennial plastics show in Düsseldorf, Germany, challenges injection molding machine builders to demonstrate technological leadership in addressing the needs of the marketplace.

Read MoreK 2013 Preview: Injection Molding

Next month’s mammoth triennial plastics show in Düsseldorf, Germany, challenges injection molding machine builders to demonstrate technological leadership in addressing the needs of the marketplace.

Read More

.png;maxWidth=300;quality=90)