INJECTION MOLDING: Automation and Integration At K Show

There were new presses of all stripes aplenty at K 2010, but the “wow” factor was supplied by automated work cells and integrated manu-facturing systems performing multiple operations before, during, and after molding.

There were new presses of all stripes aplenty at K 2010, but the “wow” factor was supplied by automated work cells and integrated manufacturing systems performing multiple operations before, during, and after molding. Here’s a selection of some of these eye-catching exhibits. For a more complete picture of the show news, see also our September K Preview. And upcoming articles will cover more show news in hot runners, robots, and controls.

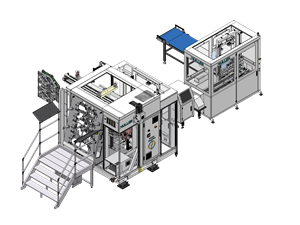

UNUSUAL INTEGRATION

As reported last month, Engel and KraussMaffei operated two of the most elaborate integrated cells at the show, making organic hybrid composites. They involved preheating, forming, and overmolding a woven-glass/nylon composite sheet. KM also compounded the long-glass overmolding compound on its IMC injection molding compounder. In Engel’s case, the final product was laser trimmed outside the mold. In KM’s cell, the robot took the net-shape part to a quality check station and then put it on

a conveyor. Engel’s cell used two linear robots and a six-axis articulated robot. KM used a single LRX linear robot plus a simple moving arm to transfer the hot sheet in and out of the oven and from oven to mold.

Engel and KraussMaffei also both demonstrated machine systems for injecting and overmolding a thermoplastic substrate with two-component liquid thermoset PUR. In both cases, the PUR was applied as a thin, scratch-resistant varnish. Engel (engelglobal.com/na) combined its Clearmelt process with back-injecting a wood veneer insert. KM (kraussmaffei.com) combined its ColorForm process with two-component molding of a carrying case of ABS and TPU soft-touch material. The high-gloss PUR varnish was overmolded selectively onto the ABS substrate.

KM also demonstrated the latest version of its CoverForm system for overmolding an acrylic part with a liquid acrylate hard coating. The coating partially cures with heat in the mold; cure is completed in a UV tunnel after demolding. This year, KM added one more wrinkle: The coated parts were then placed by a robot into a compact vacuum metalizer standing beside the press. A chrome-finished truck mirror emerged from the metalizer in 80 sec. The PlastiCoater PVD metalizer holds up to four parts; it comes from Impact Coatings AB (impactcoatings.se) in Sweden.

Arburg (arburg.us) demonstrated insert molding, multi-component overmolding, in-mold magnetization, in-mold assembly, and post-mold robotic assembly in a cell producing a rotary encoder with a magnetic sensor. Ferrite-filled nylon material was first oriented and magnetized in the mold during injection. An Arburg Multilift V robot (arranged longitudinally along the machine axis) then transferred the magnetic disk to a second station on the ejector side while also inserting a sensor component into the second station on the nozzle side. Glass-filled PBT was injected to encapsulate the sensor and form the mounting plate for the magnetic disk with a post extending through the center hole in the disk. In this partial overmolding and in-mold assembly step, the incompatible nylon and PBT separated when cooled, so that the disk rotated freely on the mounting plate to which it was joined. At the same time, an MABS protective cap was molded in a third mold station. Finally, the robot removed the assembly and cap and assembled them together.

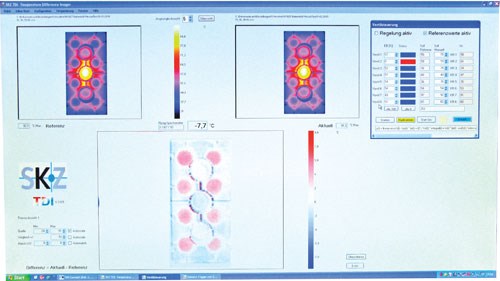

Wittmann Battenfeld (wittmann-group.com) incorporated two unusual downstream quality checks into its molding exhibits. One was an online thermography system from the South German Plastics Center, known as SKZ Wurzburg (www.skz.de). On each cycle, the robot presented five sides of the part to an infrared camera mounted on the robot beam. The software showed a color-coded PC screen display of the part’s surface-temperature profile, as well as a comparison with a “good part” profile. (Precise temperature and temperature-difference values appeared when mousing over the image.) If the temperature profile varied, the SKZ software automatically adjusted the coolant valves on the mold. (Look for more on thermography in an upcoming issue.)

Wittmann Battenfeld also measured the surface profile (smoothness) of a part produced by the new Ball-Filled Mold (BF Mold) process. It uses a mold with a large heat-transfer chamber filled with steel balls to apply rapid mold heating and cooling in order to achieve highly cosmetic surfaces. After molding, the robot presented the part to a vision system using patented measurement technology from PCCL, the Polymer Competence Center Leoben in Austria (pccl.at). The software, engineered to mimic human visual perception, analyzes part surfaces for gloss variations, weld lines, sinks, and moisture streaks.

High-speed 100% QC monitoring of bottlecaps at 1800/min was demonstrated by Sumitomo (SHI) Demag (demag-usa.com). The company’s El-Exis SP 300-2500 hybrid molded caps in 72 cavities and less than 2.5-sec cycle. The caps fed on a conveyor past three color cameras and strobe lights of an IMD Vista system from IMD Ltd. (IMD USA Corp. is in Venice, Fla.; imdvista.com). The system inspected the inside, outside, and top surfaces of the caps and automatically separated any rejects. It’s said to be capable of inspecting 3000 caps/min.

Two process technologies that got a lot of play at K were in-mold labeling (IML) and multi-material/multi-shot molding. Engel and Sumitomo Demag upped the level of complexity by doing both at once—and Sumitomo used two different films in one part (see our September preview and last month’s Starting Up section).

Since many of the elaborate workcell demonstrations employed six-axis articulated robots, it’s worth noting that Engel showed full integration of a Staubli robot with its RC 200 press controller, while Arburg fully integrated a Kuka robot with its Selogica control interface.

NEW MACHINES

Our September preview covered several new lines and models of machines introduced by Arburg, Engel, Haitian, Husky, Negri Bossi, Netstal, Sumitomo Demag, and Wittmann Battenfeld. These included electric, hydraulic, and hybrid presses. A brand-new series from Ferromatik Milacron (ferromatik.com) is all of these: Its F-Series will offer a choice of electric or hydraulic drive of clamp, injection, plastication, ejection, and carriage movement. This fully modular approach will gradually replace all its other lines (Elektra, K-Tec, and Vitesse) over the next two years. The line will span 50 to 650 metric tons (m.t.), but the first available will be 80, 160, and 350 tons, initially with only electric-driven toggle clamp and hydraulic carriage movement.

Few details were available before the show on Negri Bossi’s (negribossi.com) new Vesta series of all-electric toggle presses (no hydraulics, not even on the ejector). This completely new design has new Siemens motors with high current/torque ratio, new control software, new fiber-optic controls and touchscreen, and belt drives (no gears) for very smooth movements. Regenerative electric drives recover energy during braking. Maximum injection speed is 230 mm/sec. Seven models span 88 to 475 tons.

When it comes to speed, Arburg is revisiting the concept of linear servo motors for super-fast injection—up to 2000 mm/sec, previously achievable only with a hydraulic accumulator. This direct-coupled motor achieves an acceleration rate of 8G, 12 times higher than a standard electric machine. The product of collaboration between Siemens and Arburg, the linear motor was shown on an electric Allrounder 370A with 50-m.t. clamp and 18-mm screw. Besides high speed, the linear motor has no moving parts and is therefore wear-free, according to Arburg. Even at high speeds, the motor remains controllable and “absolutely play-free” for maximum precision and reproducibility. The company also says this technology opens up previously impossible thin-wall applications down to 0.2 mm with flow-length/wall-thickness ratios of 200:1 to 300:1.

Linear electric drive for injection speed of 2000 mm/sec was first introduced on the Fanuc Supershot machine by Cincinnati Milacron (milacron.com) at NPE in 2000, but it was discontinued. The new, more powerful linear motor reportedly overcomes limitations of previous versions. However, it adds cost and Arburg regards it as a niche product for extremely thin-wall products.

(Note: Fanuc came out in 2009 with a 100-m.t. Roboshot S-2000i100BH, which has a new high-powered rotary servo motor capable of 3.6G acceleration and injection at 1000 mm/sec. It is directly coupled to the ball screw.)

As reported in October, Husky Injection Molding Systems (husky.ca) launched its first all-electric machines at K—the 180-m.t. H-PET AE system for low-volume molding of PET preforms, and the 100-m.t. H-MED AE system for cleanroom medical molding. Aimed at the custom preform market, the H-PET system is suitable for up to 32 cavities or around 12,000 preforms/hr.

Husky also unveiled an improved version of its High Performance Package (HPP) for the HyPET hybrid preform molding system. Compared with the first generation introduced at K 2007, HyPET HPP offers 5% faster cycles (that’s 20% to 25% faster than a non-HPP system) and is 10% to 15% more energy efficienct than standard HyPET systems. A 400-ton press molded 9.9-g EcoBase preforms for 0.5L water bottles in 96 cavities in 5.2-sec, for a total of 66,000 preforms/hr.

Also new was a major upgrade to Husky’s HyPET Recycled Flake (RF) system. First introduced as a prototype in 2009, designed to mold preforms from up to 50% recycled flake, it now can handle up to 100% post-consumer recycle (PCR) with “significantly reduced black specks and dramatically minimized failures during bottle blowing,” according to Husky. Output is said to be the same as a standard HyPET system. The first system is in commercial production at a European beverage company. The current system is designed to handle washed and decontaminated flake, but Husky is working on a system using only washed flake, with decontamination occurring during preform molding.

Given the rising popularity of servo-pump hydraulic drives for energy savings approaching those of electric machines, Engel now offers its Ecodrive option on all its hydraulic machines. And Boy Machines (boymachines.com) upgraded its Boy 35 E (35 m.t.) with a new servo-pump drive (previously available on larger 55 E and 90 E models). This is said to reduce both noise and cycle times through faster response. Also new on the 35 E is a swiveling injector to allow faster cylinder and nozzle changes. And the 35 E footprint has been reduced 10% to 1.9 ft2. At the same time, Boy introduced the vertical-clamp Boy 35 E HV for parting-line injection and the vertical/vertical Boy 35 E VV for insert molding.

The star of Haitian’s exhibit was its new Zhafir Mercury all-electric, tiebarless machine with two-stage, screw/plunger injection. This German-built machine (supplied here by Absolute Haitian, absolutehaitian.com) supports and guides the moving platen with linear bearings on the top and bottom of both side plates. It is said to provide 70% more mold area while being 30% slimmer than a comparable tiebar machine. The machine boasts a simplified toggle mechanism that needs no lubrication, energy recovery during braking, adjustable-height control panel for operator convenience, and injection acceleration of over 10G for speeds up to 500 mm/sec. Models of 55, 110, and 150 tons will be available this year. The first, unit, a 150-tonner, has been in trials since September at packaging molder SIM in France. It has run a two-cavity PP honey cup (750 ml) weighing 21 g with a 0.6-mm wall in 3.9 sec. Part-weight uniformity is said to be better than ±0.2%.

LSR molding is a new capability for the 6-ton tabletop Babyplast press from Rambaldi & Co. in Italy (sold here by Alba Enterprises, albaent.com). This hydraulic plunger unit has a 15-g shot capacity and and shutoff nozzle; it dispenses from cartridges. Up to five machines can be networked to a single PC.

Related Content

New In-Mold Labeling System Launches at K 2022

Muller Technology’s IML production cell will produce a round container in an 8-cavity mold with vison inspection and downstream automation.

Read MoreKurz Opens New Plant in Vietnam

The maker of decorative thin films invested 37 million euros in the new 60,000-m2 plant in Quy Nhơn, which joins regional production facilities in China and Malaysia.

Read MoreBorealis and Bockatech Showcasing Ultra-Lightweight Reusable PP Cups

Use of Borealis PP and Bockatech’s EconCore next-generation foaming technology yields thin-wall, robust and fully recyclable cups.

Read MoreIn-Mold Labeling Applied to Medical

In collaboration with multiple partners, Arburg will showcase IML for centrifuge tubes at Fakuma 2023, eliminating printing or other downstream steps.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More

.png;maxWidth=300;quality=90)