Keeping Track of 4300 Products

Rowmark LLC in Findlay, Ohio, is an extruder of specialized sheet materials for engraving, architectural signage, awards, and identification.

Rowmark LLC in Findlay, Ohio, is an extruder of specialized sheet materials for engraving, architectural signage, awards, and identification. Originally a division of Hancor Inc., Rowmark became an independent company in 1997 and has since tripled in size, expanded from one extrusion line to three, and started new divisions supplying thermoforming and other specialty markets.

What has always distinguished Rowmark is its enormous range of choices of color, gauge, and surface texture–4300 different products, or SKUs (stock keeping units) in inventory jargon. “We’re a high-SKU, low-quantity manufacturer,” says president Duane Jebbett. That’s Rowmark’s competitive advantage, but it also became a major headache early on.

Of 4300 SKUs, only 300 are high-volume sheet products produced every three to four weeks. These account for 80% of sales. The other 4000 sheet products are sold a few at a time. The company specializes in coextruded, laminated, and custom products, including custom color matching.

BAR CODES TO THE RESCUE

From the beginning, Rowmark used enterprise resource planning (ERP) software from DTR Software (now part of Consona Corp. in Indianapolis). But the ERP system was oriented toward sales and purchasing. It kept track of sheet orders and raw-material purchasing, but didn’t effectively integrate production or manage inventory. As Rowmark grew, so did problems with shipping errors and customer complaints.

In 2001, Rowmark began a complete overhaul of its warehousing system. At the time, sheets were stored in cardboard boxes hand-marked with the part number. Orders were filled in two steps. One person counted the sheets by hand. A second person then recounted the order before it was shipped. But the second person had to rely on memory and eyesight for color and finish identification, which was nearly impossible with so many SKUs.

Rowmark extended its ERP software system with assistance from Integrated Manufacturing Systems Inc. in Merrimack, N.H., and converted from hand-written labels to barcoding for more accurate inventory management, stocking, reordering, and shipping. Rowmark installed new material storage racks and barcoded raw materials inventory, so that pulling resins and pigments no longer had to be done from memory.

At the same time, Rowmark worked with its largest customers to put them on an electronic data interchange (EDI) system, whereby they entered their own orders directly into Rowmark’s ERP system. Rowmark managed to channel 70% of all orders through direct EDI. This saved time and avoided errors from re-keying orders in-house. Improved accuracy with direct customer ordering translated into improved forecasting of product demand and production scheduling, using software from CorVu Integration (part of Rocket Software) in Edina, Minn.

“We have not conducted a wall-to-wall inventory count in more than four years,” says Rowmark materials manager Bob Holderman. “Instead, we audit the ERP system by counting finished products, raw materials, and work in progress in particular storage locations at regular intervals to verify the accuracy of the system.”

By 2007, these efforts were paying off. Rowmark had reduced finished goods inventory by 17%, increased inventory accuracy from 70% to over 99%, and improved the accuracy of filling customer orders from 80% to 99.7%.

Rowmark continues to enhance its ERP system. A year and a half ago, Rowmark added master scheduling software for production planning and scheduling. It also developed a very efficient order-picking methodology within the barcoding system. Now when the shipping department fills an order, the system sets the employee’s route through the warehouse, indicating the order in which products should be picked for optimum efficiency.

Barcoding has also improved, with an embedded identifier for each individual sheet, so packers no longer scan the top sheet 10 times when filling an order and then hand count and pull 10 sheets. The scanner has to identify each sheet, reducing the risk of errors.

Related Content

Formulating LLDPE/LDPE Blends For Abuse–Resistant Blown Film

A new study shows how the type and amount of LDPE in blends with LLDPE affect the processing and strength/toughness properties of blown film. Data are shown for both LDPE-rich and LLDPE-rich blends.

Read MoreHow Much L/D Do You Really Need?

Just like selecting the extruder size and drive combination, the L/D should be carefully evaluated.

Read MoreUnderstanding the ‘Science’ of Color

And as with all sciences, there are fundamentals that must be considered to do color right. Here’s a helpful start.

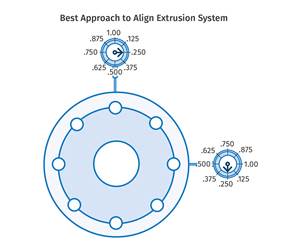

Read MoreExtruder Alignment: Important, but Only Half the Equation

The other half? Aligning and supporting downstream equipment. Here are best practices.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More