New Resins & Additives Galore at K 2016

A wide range of interesting developments in materials technologies were sprinkled in with some intriguing announcements of new ventures at K 2016.

A broad range of new materials and additives were featured at K 2016, ranging from novel engineering resins and thermoplastic composites to specialty polyolefins, as well as stabilizers and other additives to boost performance of materials. Key target markets include automotive, packaging, electronics, building/ construction, healthcare, sports, and other consumer goods. And as always at the big show, there were some intriguing business announcements:

Celanese Engineered Materials (U.S. office in Irving, Texas) is entering the TPE business via the acquisition of Italy’s So.F.TER., and will also expand its engineering plastics portfolio with So.F.TER.’s reinforced PP, nylons 6 and 66, PBT, PC/ABS, ABS, PC, PS, SAN, and PPE compounds.

Celanese also announced its entry into the PEEK market with a special high-flow product. Celanese says it plans to use its LCP expertise for complex PEEK geometric shapes targeting underhood automotive and electronics applications.

SABIC (U.S. office in Houston) confirmed that it is evaluating building a petrochemical and derivatives complex—including polyolefins—either in Texas or Louisiana, in conjunction with an ExxonMobil Chemical Co. affiliate. SABIC also announced that by end of this year, it will produce glass-reinforced acetal for global applications in automotive, building/construction, and more.

Italy’s Radici Group Performance Plastics (U.S. division, Radici Plastics USA Inc., Wadsworth, Ohio) highlighted further expansion of its nylon business in North America and Europe though its acquisition of INVISTA Engineering Polymer Solutions unit (Wichita, Kan.), which produces Torzen nylon 66 reinforced, filled, toughened, and flame-retardant compounds.

Solvay Specialty Polymers (Alpharetta, Ga.) said it expects to increase global capacity for its high-performance sulfone polymers—Udel PSU, Radel PPSU, and Veradel PESU— by over 35% in the next five years through optimization of U.S. and Asian plants.

Solvay Engineering Plastics unveiled Technyl 4 Earth, a 100% post-industrial nylon 66 sourced from auto airbags. It is enabled by a patented technology capable of separating the nylon from the airbag’s silicone. The material reportedly has properties equivalent to virgin nylon 66. Potential applications include automotive air filters as well as electronic components and consumer goods.

The company also launched Technyl REDx, a new high-heat nylon 66 based on a patented technology that eliminates the need for heat stabilizers. This material transforms when exposed to heat during use from a thermoplastic to a thermoset with enhanced properties. The crosslinking is irreversible, so parts made of Technyl REDx cannot be remolded under standard conditions. The material sports temperature resistance of 220 C, approaching that of PPA (220-240 C) and surpassing standard nylon 66 at 190-200 C. Processability is said to be akin to a typical nylon 66 with excellent flow.

As previously reported, both BASF Corporation - Engineering Plastics and DSM Engineering Plastics (DSM Engineering Plastics North America, Troy, Mich.) launched new high-performance PPAs for automotive applications. BASF’s new Ultramid Advanced N was used in the complex and compact electronic assemblies of the Hyundai RN30 concept car highlighted at the show. The resin can also be used in structural parts near the engine and the gearbox.

Similarly, DSM showcased some target applications—including powertrain, transmission, chassis, and thermal-management components, for its new Stanyl ForTii Ace. This is DSM’s third-generation polyamide 4T and is touted as the first PPA to be positioned to replace die-cast metals and costlier engineering resins like PEEK.

SPECIALTY NYLONS SHINE

The BASF/Hyundai concept car also featured BASF’s Ultracom thermoplastic composites, first launched at K 2013, the result of BASF’s alliance with TenCate and Owens Corning. Ultracom laminates are based on woven fabrics and unidirectional tapes impregnated with BASF’s Ultramid nylon or Ultradur PBT resins. In the concept car, Ultracom was featured in parts with complex geometry such as the injection molded seat shell and pan, making the seat lighter while maintaining optimum strength and rigidity.

A third new family of PPA resins was launched by the Radici Group. Radilon Aestus T is said to deliver not only the highest temperature resistance, but also high flame resistance and chemical resistance, especially to aggressive fluids. Other key characteristics include: high melting temperature and heat-distortion temperature; excellent resistance to prolonged aging in air and a glycol-alcohol-gasoline blend; and good flowability, allowing for very thin-walled parts. Markets include automotive fuel connectors and thermostat housings; water/plumbing fittings; beverage-dispensing equipment; and electrical/electronic components.

Teknor Apex Co., Pawtucket, R.I., showcased its new nylon 612 extrusion compound for automotive cable jackets. Approved by GM and Chrysler for heat-stabilized nylon 612, Chemlon 890 HNT001 boasts better chemical resistance than nylon 6 and reportedly has greater stress corrosion resistance when exposed to aggressive chemicals or mechanical stresses. It is currently used in brake jacketing for a U.S. OEM, having passed the cable supplier’s heat-aging test of 135 C for 168 hr.

As previously reported, other new specialty nylons—including high-flow, flame- retardant, and micro-bead and hollow-bead reinforced compounds—were showcased by LANXESS Corporation (U.S. office in Pittsburgh), Houston-based Ascend Performance Materials LLC, and So.F.TER. (U.S. office in Lebanon, Tenn.).

MORE NEWS IN ENGINEERING RESINS

Particularly for automotive/transportation applications, new PC PC/ABS, PC/PBT resins (previously reported) continue to make a splash. For example, Covestro LLC (U.S. office in Pittsburgh) showcased new Makrolon PC grades in a range of emerging applications. They were featured on the electric concept car at the show, including its wrap-around PC glazing.

Also on this concept car was an entirely new lighting concept, the key to which is seamless integration of the PC body with the PC lighting structure. Also, an interesting holographic lighting function in the rear of this vehicle—an extremely thin design with PC LED backlights, was said to be a “first”. Covestro also showcased a new process of making steering wheels instead of spray painting, they injection mold the PC or PC/ABS part and in the same mold inject a PUR coating.

SABIC also sported PC glazing for automotive rear windows, carbon-fiber-reinforced PC/ABS for transportation applications, and new PC copolymers for injection molding aircraft-interior parts. The company showcased a new Scania big-rig truck that features 30 different applications utilizing SABIC materials.

Among them are a Cycoloy PC/ABS instrument panel, Xenoy PC/ PBT upper side-step panel and mud guards, and Stamax long-glass PP storage boxes, mounting panes, and guide rails. SABIC also showcased PC sheet for the healthcare sector. In the electronics arena, Covestro featured its newly developed continuous carbon-fiber sheet impregnated with PC, demonstrated in next-generation laptop housings. Flextronics formed the composite sheets.

Spain’s Elix Polymers (Elix Polymers Americas LLC, Weston, Fla.) showcased new specialty ABS, including high-heat grades and a new generation of plateable grades for automotive. The company also showed new blends of ABS with biopolymers and natural fibers.

Solvay featured a newly modified version of Ryton R4 40% glass- filled PPS for an injection molded impeller and stator isolator of the electric pump of the Polimotor 2 all-plastic race-car engine.

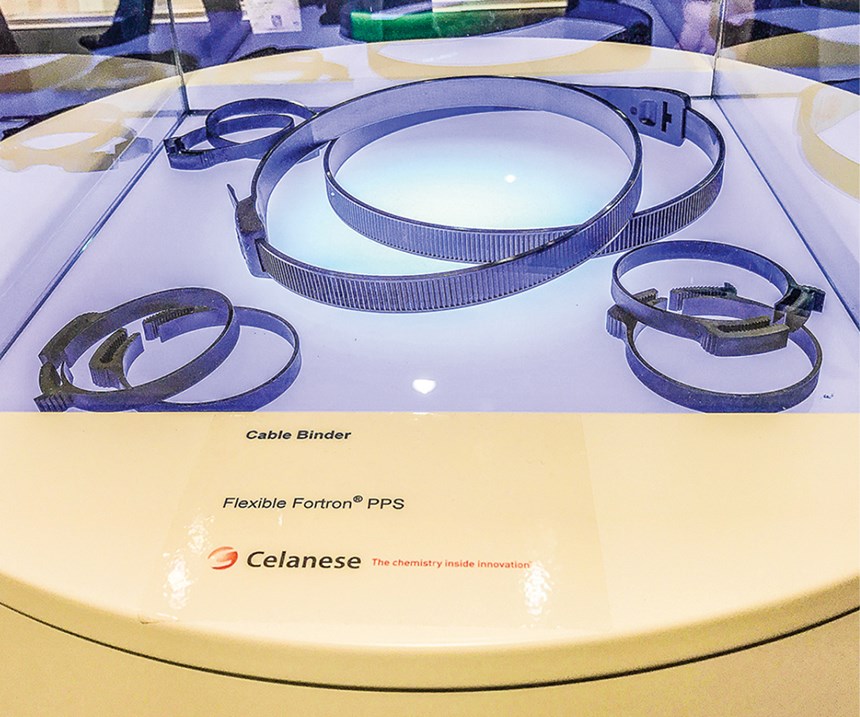

Celanese unveiled what is said to be the first flexible Fortron PPS for cable ties for materials handling, agricultural equipment, and automotive. It is positioned to compete with nylon cable ties by offering better heat resistance.

Ineos Styrolution, Aurora, Ill., unveiled what is believed to be the first styrenic-based thermoplastic composite, said to exceed the mechanical properties of composites based on nylon 6 or PC. Based on a modified SAN, Stylight composite is offered with glass or carbon-fiber fabrics for aesthetic/semi-structural as well as structural applications in automotive, truck interior and exterior panels, seat structures, and center consoles. Stylight grades are offered as semifinished thermoplastic sheets, ready for processing via thermoforming and overmolding. The company also offers three glass-filled ABS/ nylon 6 grades and one ABS grade for back-injection or overmolding of Stylight parts.

NEWS IN POLYOLEFINS

New and improved polyolefins and polyolefin elastomers (POEs) also made their debut. For example, Dow Chemical Company, Midland, Mich., introduced Agility EZ 7000, a new LDPE for extrusion coating that boasts the highest melt strength available in such a material. Dow also highlighted new Engage XST, the latest metallocene POE designed for use as an impact modifier in automotive TPOs. It’s already used in bumpers and airbag covers.

Brazil's Braskem (Braskem America Inc., Philadelphia) unveiled a high-gloss HDPE for injection stretch-blow molding. It boasts 80% higher gloss than competitive grades without sacrificing properties, plus excellent scratch resistance. This HDPE can be molded as the outer layer of HDPE bottles from very small sizes up to 5 liters. Also new from Braskem was Flexus Cling, its first cast cling-film grade, which now completes the company’s LLDPE portfolio.

Braskem also launched high-melt-strength PP for foams. This HMS-PP is touted for its excellent chemical and temperature resistance and ability to produce low densities that approach those of automotive PUR foams. It was slated to be used in a door-liner application before 2016’s end, and will be in a headliner application, replacing a phenolic resin, this year.

As previously reported, other new polyolefins were launched by ExxonMobil Chemical, SABIC, Borealis, and Nova Chemicals.

NEW ADDITIVES

Additives launched at the show included stabilizers for automotive PP and TPO and other applications; pigments and colorants; chain extenders; laser-marking additives; slip and anti-scratch additives; and thermally conductive fillers.

• Stabilizers and antioxidants: Solvay Specialty Chemicals featured its new Cyasorb Cynergy Solutions V Series stabilizers for automotive TPO. They are said to protect against UV light, extreme temperatures, and other environmental factors. Other new stabilizers (see September show preview) included Tinuvin 880 HALS from BASF Corporation - Plastic Additives (Florham Park, N.J.), a novel, long-lasting and thermally stable UV stabilizer; and Songxtend 2124 from Songwon (Songwon International-Americas, Inc., Houston), which provides long-term thermal stability for glass-reinforced PP interior components.

Proprietary heat stabilizer technology for use with recycled materials was unveiled by Baerlocher (U.S. office in Cincinnati, Ohio). These Baeropol T-Blends are metallic stearates aimed primarily at polyolefins but also look promising for PS, nylons, and acetals. These stabilizer blends reportedly can reduce or totally eliminate the need for phosphite. Unlike phosphites, the T-Blends have no solubility limitations and thus no tendency to plate out or form gels in high-speed extrusion.

Addivant, Danbury, Conn., unveiled new hindered phenolic antioxidants for HBCD-free flame-retardant EPS. Lowinox XPS 162 boasts 50% better stabilization and 10 times less discoloration. Also new is Lowinox Fast CL antioxidant, said to boost productivity of XLPE power-cable lines at lower cost. Addivant also showcased new Ultranox 800 phosphite antioxidant, which boasts cutting-edge color and process stability with enhanced cost savings for PP compounds.

• Pigments/Colorants: BASF Colors & Effects showcased new Lumina Royal Dragon Gold EH 0908, a brilliant green-shade gold mica effect pigment. It is said to offer the highest lightness and strongest sparkle in styling for yellows and greens, and to extend the color-space potential of high-chroma shades for packaging, consumer electronics, household appliances, sporting goods, and other specialty applications.

PolyOne, Cleveland, launched a new colorant technology developed with Germany’s Merck KGaA that allows plastics processors to create flat surfaces that appear to have depth and structure. IM3D technology creates a 3D impression in a single step during injection molding, versus the several processing steps previously required to generate such a surface effect.

Also showcased by PolyOne was the new Impress family of ultra-glossy metallic colorants, available in solid or a liquid form. They reportedly enable pack- aging manufacturers to realize unlimited combinations of color and gloss to create packaging with a brilliant, attention-grabbing appearance free of flow lines. These colorants are well suited to packaging made with PET, PC, and ABS processed on standard blow molding machinery. PolyOne also launched new grades of its OnCap laser-marking pigments that reportedly achieve good marking with the newest, fastest laser-marking equipment for wire and cable.

As previously reported, several other novel pigments were showcased by Modern Dispersions, Inc., Huntsman, Clariant, and Lanxess’ Rhein Chemie Additives.

• Chain extenders, compatibilizers: Vertellus launched three new ZeMac masterbatches: Extend L65 and L68 are chain extenders and branching agents that convert low-relative-viscosity (RV) nylon to branched high-RV nylon with better thermal and mechanical performance than linear nylon. Meanwhile, new Extend P62 is said to be the only product in the market able to smoothly compatibilize nylon and recycled PET to reduce material costs.

• Slip and anti-scratch additives: Dow Corning, Midland, Mich., introduced a high-molecular-weight, long-chain, non-migratory silicone slip agent developed specifically for LL/LDPE films for form-fill-seal food packaging. The company will soon launch a silicone-based slip agent for BOPP. Croda Inc. (U.S. office in Arlington, Tex.) launched two anti-scratch additives for PP: Incromold K, said to reduce scratch visibility and whitening in PP impact copolymer; and Incroslip G, a stable product said to exhibit excellent anti-scratch properties in PP homopolymer with an added benefit of improving mold release.

• Thermally conductive fillers: Martinswerk, a Huber Engineered Materials, Atlanta, showcased its new Martoxid series of heat-conductive, alumina-based fillers designed to improve compatibility of filler and matrix resin. They are said to allow for high loadings to transfer heat away from electronic parts made from a wide range of thermoplastics. (See Keeping Up for more additives news at K 2016.)

Related Content

Foam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

Read MoreABC Technologies to Acquire Windsor Mold Group Technologies

The Tier One automotive supplier with compounding and blowmolding machine capabilities adds the 50-yr-old molder and moldmaker.

Read More‘Monomaterial’ Trend in Packaging and Beyond Will Only Thrive

In terms of sustainability measures, monomaterial structures are already making good headway and will evolve even further.

Read MoreIn Sustainable Packaging, the Word is ‘Monomaterial’

In both flexible and rigid packaging, the trend is to replace multimaterial laminates, coextrusions and “composites” with single-material structures, usually based on PE or PP. Nonpackaging applications are following suit.

Read MoreRead Next

Why (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More

.png;maxWidth=300;quality=90)