Non-Contact IR Analysis Simplifies On-Line Quality Control

A new method of mid-infrared analysis allows on-line monitoring of both the composition and physical properties of a plastic while it is being compounded or extruded.

A new method of mid-infrared analysis allows on-line monitoring of both the composition and physical properties of a plastic while it is being compounded or extruded. Up to now, mid-IR spectroscopy was limited to use in the laboratory and only for gases. The new technique, Transient Infrared Spectroscopy (TIRS), was developed at the Ames Laboratory, a U.S. Dept. of Energy lab at Iowa State University. It performs non-contact, real-time monitoring of solid or melt-phase process streams.

TIRS has been demonstrated on a wide variety of process lines at speeds of 4 cm/sec to 20 meters/sec. It can monitor blend composition, cure level, layer thickness, tensile strength, and any other property that correlates with a material’s IR spectrum. The Iowa State Univ. Research Foundation holds patents on the technique, but a license is not required because TIRS was developed with government grants.

According to Roger Jones, one of the developers, a TIRS system is said to be simple to assemble from off-the-shelf components, using either a Fourier Transform Infrared (FTIR) spectrometer or a non-dispersive IR detector.

How it works

A type of emission spectroscopy, TIRS uses the spontaneous mid-infrared emission that all materials give off by virtue of their temperature. The hotter they are, the more mid-IR radiation they emit. Conventional mid-IR spectroscopy requires that solid samples be very thin so IR radiation can be transmitted through them, or that they be very smooth and stationary so radiation can be reflected off them in reproducible fashion. In conventional emission spectroscopy, a sample is warmed above ambient temperature until it emits sufficient IR light, and then the emission spectrum is recorded.

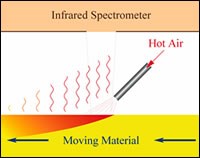

According to Jones, very thin, warm samples emit primarily at the same wavelength that they preferentially absorb when IR is passed through them, so analysis of the spectra is identical to conventional transmission spectroscopy. But if a warm sample is too thick, it emits all wavelengths, resulting in a featureless “blackbody” spectrum. TIRS overcomes this limitation through use of a small jet of warm or cool air to strike a moving process stream as it passes an IR spectrometer.

With a warm air jet, the heated surface layer of plastic acts as a thin emission source separate from the rest of the process stream. Because it is thin, it produces a structured, analytically useful spectrum, similar to that which would be produced with a physically thin sample. This structured emission is easily distinguished from the featureless blackbody radiation of the underlying material stream. Since the material is moving, the heated layer passes out of the spectrometer’s field of view before it can thicken and cool.

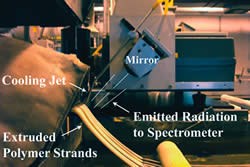

A cooling air jet can be used for materials above ambient temperature, such as plastic melt strands emerging from an extruder. The cool jet produces a thin, cooler layer on the surface of the strand. The cooled layer emits less IR because of its lower temperature. This layer absorbs IR radiation from the hotter core of the material, so the spectrometer observes a structured transmission spectrum for the cooled layer similar to conventional transmission spectroscopy.

What’s special about TIRS

In making the plastic stream appear thin to the spectrometer, TIRS differs from other on-line IR methods, which perform transmission spectroscopy through the melt by forcing a side stream of melt from the extruder through a spectroscopy cell. That cell must be very narrow or else the melt will be completely opaque in the mid-infrared. The thin cells have a tendency to clog and become contaminated with residual material deposits, Jones notes.

With non-contact TIRS, there is no manipulation of the process stream or changes to the process line. In tests performed by GE Plastics at Mt. Vernon, Ind., the TIRS unit was positioned next to the extruder die to observe the strands as they left the die. In these tests, TIRS analyzed the composition of a PC/PBT/ABS blend as it emerged from an extruder.

TIRS also has advantages over near-IR (NIR) spectrometry, says Jones. “Absorption peaks in the NIR range are much weaker and broader than mid-IR.” That does allow much thicker melt streams to be analyzed than with mid-IR. “This gets around cell clogging, but it is still a contact measurement” and requires a side stream. Because NIR peaks overlap a great deal, chemometric analyses are essential for making sense of the spectra. Chemometrics are also used to get more precise results with TIRS, but its spectra can be analyzed by classic methods, since the height of individual peaks often correlates with concentrations of specific components.

Anatomy of a TIRS system

TIRS uses either an FTIR spectrometer or a non-dispersive IR detector. The size and location of peaks in the emission spectrum correlate with the composition and other properties of the test material.

Where only one property is to be determined, the strength of a single peak is sufficient, so that a non-dispersive IR detector tuned to that peak suffices, which reduces the monitor size and cost. An FTIR detector is called for when multiple properties are monitored or where there is a need for increased accuracy and reliability.

The Ames Laboratory TIRS unit includes an FTIR spectrometer. Fixtures were added for a mirror to aim the spectrometer at the process stream and for the TIRS air jet. The warm-jet version employs a hot-air gun such as is used to seal plastic bags. For the cool-jet version, a blower nozzle aims a stream of ambient air.

Chemometric partial-least-square (PLS) analysis is used to correlate whole spectra with the properties to be determined. PLS builds a model that relates the two using a “training set” of spectra for samples whose properties have been measured off-line by a reference method. This model allows TIRS with an FTIR system to acquire a mid-infrared spectrum and convert it into an analysis in as little as 2 sec. Systems with non-dispersive detectors are even faster. By shifting the distance between the air jet and the IR detector, users can change how long the induced cool or warm surface layer thickens before its spectrum is measured. This adjusts how deeply into the moving material the TIRS unit observes, limited only by how opaque the material is to IR radiation.

In one trial, TIRS was used by staff at Eastman Kodak to monitor layer thickness in an extrusion coating system that applies two polymer coatings—a main layer and a tie layer—simultaneously to a paper substrate. Says Jones, “We were able to measure the thickness of each of the layers separately using the TIRS spectra by the relative changes in peaks arising from the main layer, the tie layer, and the substrate.”

TIRS was also used to determine tensile strength of soy protein polymers made by researchers at Iowa State. Says Jones, “We were able to correlate our TIRS spectra with tensile strength. The strength of the material was changed by varying both the concentration of an additive—a compositional property—and the extruder screw speed—a non-compositional process parameter. TIRS could track changes produced by either method.”

Related Content

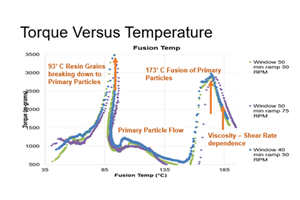

Try This Alternate Method for Heating Your Torque Rheometer

Rheometers are generally not on all the time. And most users have found that the first test run in the instrument after heating up is not very reliable and is usually discarded. Try this method instead.

Read MoreHow to Improve Quality with Offline Inspection and Analysis

Automated sample testing with a light table detects the smallest contamination in flakes, micro granulates and sample test sheets.

Read MoreExact Metrology Now Distributor of HandsOnMetrology.com

The new digital format was set up to share the benefits of 3D metrology with a global community.

Read MoreX-Ray Vision Inside Parts Gets More Affordable for Processors

Shimadzu’s new benchtop x-ray CT scanner provides internal and external metrology and flaw detection at a fraction of the previous cost.

Read MoreRead Next

Troubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More