NPE News Wrap-Up: Decorating & Painting

The Chicago show presented a whole new way to decorate. There were also plenty of improvements in ink-jet and pad printing, hot stamping, laser marking, and surface treating.

NPE 2003 attendees got to see some genuine innovations as well as the latest improvements in more traditional decorating and printing technologies. Among the most intriguing novelties at the show were a 3D digital imaging pro cess that could be a cost-effective alternative to in-mold decorating. Another is a digital ink-jet printer that provides high-quality marking along with excellent adhesion and wear resistance. Also on hand were new laser marking systems, including one that doesn’t require photosensitive pigments.

Meanwhile, Kurz, a major supplier of heat-transfer foils announced a significant expansion into hot-stamping equipment and silicone molds. Also on display was new surface-treating equipment that boasts higher performance and lower maintenance.

New 3D digital imaging

A new process for decorating plastic parts, previously available only as a service, is now available for license. The patent-pending “e-comeleon” technology was developed two years ago by UK-based E-Comeleon Ltd. as a lower-cost alternative to in-mold decorating for cell phones, computer mouse covers, and consumer goods such as electric shavers. According to E-Comeleon, rigorous testing of image durability (resistance to wear, scratching, and fading) has led OEMs such as Nokia, Motorola, Siemens, and Philips/Norelco to approve the process for decorating their products.

This semi-automated process prints custom high-resolution color images on plastic film and then uses heat and a vacuum-forming process to transfer the image onto plastic parts through dye sublimation.

In the first step, the user takes a digital photo of the image, which is then scanned electronically and stored in a Macintosh or PC using existing standard graphics software. The image is then sent to an ink-jet printer containing special cartridges of dye-sublimation inks. The image is printed on a proprietary carrier film with a special release coating.

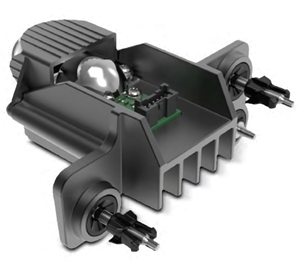

Next, the part (or parts) to be decorated is placed in the drawer of the e-comeleon 3-D Image Box—a vacuum chamber. Once the part is positioned on the template (silicone mold support), the film with the image is placed on top. The drawer is shut, a vacuum draws the film tightly over the part, and heat is applied. The dyes sublimate from the solid to the gas phase and diffuse into the surface of the plastic part.

Suitable plastics for this process must withstand temperatures over 300 F and the vacuum pressure used to transfer the image. Suitable substrate materials include PBT, PC, PC/ABS, glass-reinforced ABS, and ABS/nylon.

The largest 3-D Image Box for the process is a new model with a 27 x 19 in. bed area, which allows 40 mouse covers or 30 cell-phone covers to be decorated in one pass. Cycle times for dye transfer are between 6 and 10 min. Decorating cost comes out to about 45¢ per phone cover vs. about $1.50 for in-mold decorating, according to E-Comeleon.

In North America, technology licenses are available from Toaz, which also distributes the 3-D Image Box. Conde Systems also distributes the hardware and related products such as inks. The smaller Image Box sells for $3000, including the five-year licensing fee (not included in the price of additional lines for the same facility). The larger unit sells for $30,000 including licensing fee.

Ink-jet & pad printing

A digital ink-jet marking system originally designed for printed circuit boards is said to be a cost-effective alternative to pad printing for marking a wide range of parts from electronic and automotive components to medical devices and writing pens. It prints directly from an electronic file and eliminates pads, plates, solvents, and set-up time. The 4000 Series drop-on-demand white ink-jet marker from Markem Corp. reportedly marks a wide variety of plastics with high opacity and excellent adhesion and scratch resistance. The 4000 Series jets a highly opaque white ink at a high resolution of 600 dpi and maximum speed of 25 in./sec. Print contrast is said to be higher than that of laser markers, so that small text or machine codes are easier to read.

A new freely-programmable ink-jet printer for industrial use was launched by Metronic of Germany, represented here by PrintSafe Industrial Marking Systems. The alphaJetc4 can have up to four heads for printing dates, logos, bar codes, data matrix codes, and production data. Multiple printers can be controlled and synchronized by one master controller. The printer can operate on production lines running at up to 234 in./sec.

A new four-color pad printer from Tampoprint International has an automatic pad-cleaning function that occurs while printing takes place in a separate station. That way, cleaning does not affect output of the Concentra 60/90-4 model. Sealed ink doctoring units are mounted on a four-station index table. The machine is available with 60- or 90-mm ink cups. Maximum speed is 800 cycles/hr when using three or four colors and 900 cycles/hr with two colors. The PLC controller can store five set-ups.

New laser marking options

Two new laser marking systems made their debut at NPE. One is a small and flexible, low-power CO2 laser from Markem that is said to be very easy to integrate with automation systems due to its compact size and the ability to be mounted in a variety of positions. It is priced at less than $20,000, or 20% to 40% less than competitive systems. The Code Runner 3010CR is suitable for marking variable codes and graphics on PVC, CPVC, and thermosets. It is said to be highly reliable and easy to use, thanks to its Windows-based LaserSmith 3000 software.

Also unveiled at the show was a new frequency-tripled, diode-pumped laser marking system from Trumpf that eliminates the need for special additives such as photosensitive pigments. The VMc6’s uv wavelength of 355 nm is suited to marking electronic components such as PLCs, relays, and switches, where added pigment might change the materials’ dielectric properties. Its high photon energy is said to result in high-contrast marking through a photochemical rather than thermal process. On most plastics, the VMc6 reportedly achieves a much darker contrast than infrared lasers —without damaging the material or altering the part’s surface finish. It reportedly makes high-quality marks on ABS, PBT, PC, PPS, SAN, PEEK, and urea. Good results have also been shown with PS, ASA, PE, PVC, PET, PPS, nylon, acetal, and polyimide, depending on the color.

Hot stamping news

A new “Ink Only” heat-transfer foil for hot stamping was featured by Kurz Transfer Products. This foil reportedly can decorate parts without changing the substrate’s gloss level. The foil provides a direct printed look and is available in up to nine custom colors.

Another new entry from Kurz is the model LS 102 LK continuous hot-stamp machine, which has up to five heads for applying foil to ex tru ded profiles. The new model LS 12C LK applies foil to profiles in-line with an extrusion machine. And the new FTF 600 LK Flat Stock machine hot stamps foils into flat sheet stock.

News in surface treating

Surface-treating equipment with improved performance and low maintenance was introduced by Corotec and Enercon. Corotec upgraded its Uni-Dyne fixed-width, bare-roll corona treatment systems for narrow webs. They are available with two new features: “Works-in-a-drawer” is a removable electrode cartridge that allows for fast and easy cleaning and replacement of electrode assemblies. It is said to reduce downtime to 15-20 min vs. up to 4 hr with conventional treaters.

These treaters are also available with a new electrode design that is said to deliver much higher power densities than do competitive designs. These units are available in single- or double-side configurations with power ratings from 500 to 5000 W.

Corotec also showcased a new, economical corona treater for blown film. Its open-frame design provides easy access, and its swing-out electrodes are easy to clean. It can treat both sides of the web with fixed or adjustable width. Pneumatic operation allows “drop-through” thread-up, and external air-gap adjusters permit “tool-free” calibration. These systems sell in the range of $16,000 to $20,000, or 20% 30% less than conventional blown film treaters.

Meanwhile, Enercon came out with a new flame-plasma-treating system for 3D parts. Its sophisticated combustion-control system reportedly ensures repeatable performance and minimal downtime. Called Dyne-A-Flame, it can treat all types of extruded, pultruded, molded, and thermoformed materials, including fluoropolymers and thermosets.

Related Content

Automation in Thermoforming on the Rise

Equipment suppliers’ latest innovations exemplify this trend driven by factors such as labor shortages, higher-speed thermoformers and tighter quality control.

Read MoreSustainable Materials is Focus of Thermoforming Exhibits at K 2022

Thermoforming equipment makers including WM, Kiefel, and OMV will showcase processing of recyclable and biobased materials.

Read MoreX2F and Covestro Collaborate on Innovative In-Mold Electronics for Automotive Lighting

Thermally conductive PC heat-sinks produced with X2F controlled viscosity molding.

Read MoreHigh-Temperature Syntactic Foam and High-Slip Plug Materials for Thermoforming

At K 2022, CMT Materials to launch new Hytac syntactic foam and a developmental higher slip plug materials with no PTFE.

Read MoreRead Next

Processor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More