RECYCLING: New Melt Filtration System for Highly Contaminated Plastics

The new system from Nordson seeks to boost recycling productivity and minimize melt loss.

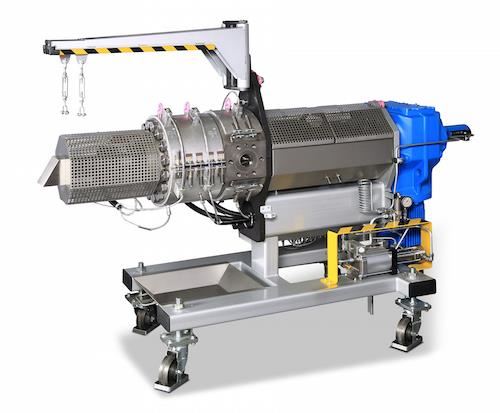

Nordson Corp., Westlake, Ohio, will introduce a new melt filtration system for recycling highly contaminated plastics at K 2016 (Hall 9, Stand A44/48).

The BKG HiCon R-Type 250 Nordson Polymer Processing Systems (PPS) equipment transforms highly contaminated polyolefin or styrenic plastics into clean, high-quality material and exhibits less melt loss than with traditional backflush systems for highly contaminated plastics, says Nordson PPS business unit director, Sven Conrad.

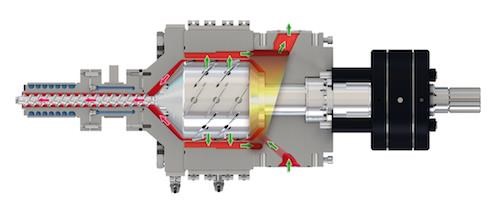

The central concept of the HiCon R-Type 250 system involves the use of a cylindrical “separating head” with knives arranged on its surface in a helical pattern designed to move contaminant particles forward as the head rotates. Enclosing the head is a stationary filter element called a “strainer tube.” When contaminated melt from an entry port flows into the cylindrical space between the rotating head and the strainer tube, the knives capture the contaminant while the contaminant-free melt moves through the strainer into flow channels that lead to an exit port. At the same time, the rotating head turns a screw which guides the contaminated material through cooling sections and finally to where it is discharged into collecting bins.

“Nordson’s newest development cleans much more efficiently than commercial available filtration systems for highly contaminated polymers,” says Conrad. “The special design makes possible a uniform load on the strainer tube during the cleaning process, providing an extended lifetime for the filter and scrapers and increasing the overall efficiency of the system at far less melt loss.”

A powerful drive actuates the separation head / discharge-screw assembly. The HiCon R-Type 250 system operates at a maximum pressure of 350 bar and maximum temperature of 320 °C. Throughput can range from 500 to 1,500 kg/h. The rate depends on polymer viscosity, filtration fineness, levels of contamination, and other factors. As it exits the system, filtered polymer is maintained at a constant pressure, ensuring uniform processing downstream.

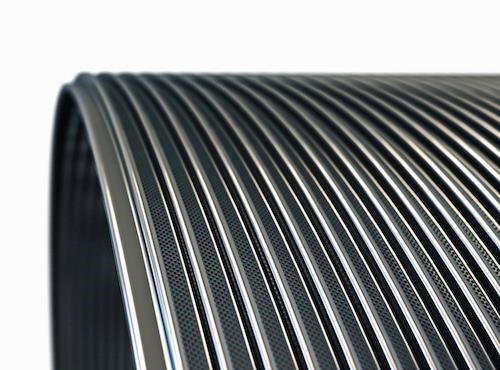

One key to the efficiency with which the HiCon R-type 250 system removes contaminants is the design of the steel strainer tubes, which are available with micro-holes ranging from 120 to 750 microns. The holes are conical in shape, permitting passage of molten polymer while preventing blockage by contaminant. This design and the symmetrically positioned knives in the drum contribute to the long working life of the tube before it needs to be replaced. Once cleaned, moreover, the tube can be reused.

Replacing a strainer tube is facilitated by a built-in swiveling arm for removing the strainer tube housing, and by a hand-operated hydraulic device for disassembling it. To ensure uninterrupted production, it is possible to operate two HiCon R-type 250 systems in parallel.

“A network of several Siemens SIMATIC control and monitoring units contributes to the high level of automation and ease of use that distinguish the HiCon R-type 250 system,” says Rolf Schultheis, Nordson PPS manager of electrical engineering. “The Siemens control system is intuitive, instantly providing a visualization of all process parameters. The onboard Ethernet / Profibus interface opens the possibility of integrating communication with other devices, collecting and recording production data, and even performing remote maintenance.”

HiCo R-type melt filtration systems are available from Nordson worldwide.

Related Content

Compatibilizers Aid Recycling & Upcycling of Mixed Resins

Compatibilizers are proving their worth in boosting critical properties such as impact/stiffness balance of PCR and PIR blends of polyolefins and other plastics.

Read MoreA Recycling Plant, Renewed

Reinvention is essential at Capital Polymers, a toll recycler that has completely transformed its operation in a short period of time.

Read MoreInside the Florida Recycler Taking on NPE’s 100% Scrap Reuse Goal

Hundreds of tons of demonstration products will be created this week. Commercial Plastics Recycling strives to recycle ALL of it.

Read MoreEnergy Company Plans to Feed Recycling Scrap Into Fuel Production

Clean Planet Energy reaches agreement with KW Plastics to Feed its Low-Sulfur Fuel Plants

Read MoreRead Next

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More