Simulation Spots Trouble Before It Starts

Blow molding has been one of the slowest processing sectors to adopt simulation software as a design and troubleshooting tool.

Blow molding has been one of the slowest processing sectors to adopt simulation software as a design and troubleshooting tool. While injection molding and some extrusion processes have exploited the benefits of simulation for well over 20 years, blow molders still appear to be a little “computer-shy.” In fact, even thermoformers appear to have embraced simulation faster than blow molders.

The areas of plastics processing that adopted simulation first were ones that had the most to lose if the product or process failed. The automotive industry placed very high demands on injection molders, making the molds expensive and forcing companies to improve efficiency and reduce delivery times. Simulation was welcomed as a form of insurance against the costs and delays inflicted by an unworkable tool design. Suppliers of large extrusion dies also realized that it made a great deal of sense to gain more confidence in the performance of their designs before cutting any steel.

In these cases, the cost of failure could easily be over $100,000. This forced injection molders and extruders to stop wasteful trial-and-error design methods and adopt simulation as a standard procedure. However, there was a perception in blow molding that the cost of failure is relatively low. Mold costs are typically lower and blow molded products are generally used in less demanding applications. This may be the main reason blow molders did not place more emphasis on simulation.

Times have changed

Over the last few years every industry has placed a stronger emphasis on cost reduction and efficiency. Most companies now realize that the true costs of product development include more than mold rework—wasted material, lost production time, and late delivery, which is probably the most important and most difficult to value. Combine this realization with the influx of inexperienced designers replacing an aging work force and you have conditions where simulation can provide a benefit.

Computer simulation allows the user to test various hypotheses in the comfort and safety of the office without the high cost, lost production time, and risk of equipment damage associated with physical experimentation on the shop floor. The benefits of simulation toward problem solving (or better yet, “virtual troubleshooting”) are demonstrated below with a few examples using the commercially available B-SIM extrusion blow molding simulation software package.

Parison profiling

The first example shows the benefit of simulation in determining parison size and shape for a relatively simple oval bottle. Figure 1 predicts the thickness variation in the bottle based on different initial parison diameters and thickness profiles. It is clear from the color contour map that a profiled parison with different thicknesses around its circumference is more successful in achieving uniform bottle thickness than merely increasing the diameter of the parison.

Figure 2 illustrates that point another way. The simulation software produced a graph of the thickness values that would be predicted to occur around the circumference of the bottle for each of the starting conditions shown in Fig. 1. The results show that the 38-mm-diam. parison resulted in very thin walls at the ends of the oval bottle shape. The 50-mm-diam. parison made the thin areas a little thicker but at the expense of extra (wasted) material on the flat sides of the bottle. The 50-mm parison with a profiled wall thickness from 1 to 2 mm resulted in a much more uniform overall wall thickness and a 25% reduction in overall material usage.

For more complex shapes, axial profiling (extrusion-direction thickness adjustment) is another wall-thickness optimization tool that can be simulated.

Poor design remedied

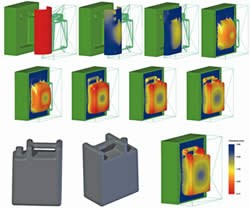

Figure 3 shows a series of steps in the simulation of blowing a fluid tank or jerry can. To the inexperienced molder, the design may appear simple enough to go ahead and build a mold. But simulation can point out some potential problems with the design.

The simulation shows that the material has some difficulty forming the top of the tank in the handle area resulting in a “web” or “wrinkle” and a very thin wall—possibly a blow-out. This would require some design change to the tank, and of course, the mold would have to be reworked if the problem were not avoided by simulation.

An experienced blow molder might be able to alert the designer to a potential problem, but the question is how much confidence the designer or molder should have that any design modification would adequately correct the problem. First, simulation can be used to help convince the part or mold designer that the design should be modified. And second, the simulation can help determine how much of a modification must be made.

Finally, it should be emphasized that the simulations presented here can be performed in a few hours using relatively inexpensive PC hardware.

Related Content

50 Years...600 Issues...and Still Counting

Matt Naitove marks his first half-century in plastics reporting, with a few of his favorite headlines.

Read MoreHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

Read MoreAvoid Four Common Traps In Granulation

Today, more than ever, granulation is an important step in the total production process. Our expert explains a few of the many common traps to avoid when thinking about granulators

Read MoreHow Inline Vision Inspection Can Minimize Scrap in Molding

Once viewed by injection and blow molders as a necessary evil, machine vision technology today can continuously monitor and improve production while reducing costs.

Read MoreRead Next

Troubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More