Thermoforming Equipment at NPE 2000 Highlighted Enhanced Continuous Roll-Fed Forming Machinery

New capabilities for continuous roll-fed forming machinery were unveiled at NPE. They include forming heavier sheet, forming lids with a tamper-evident band, and producing in-mold decorating preforms with preprinted sheet. Tooling also advanced with a new and easier way to keep the forming inserts and trim-in-place punch level after the punch is sharpened.

Roll-Feed Thicker Sheet

Higher productivity in forming thicker sheet is the goal of a new continuous, roll-fed system from ZED Industries Inc., Vandalia, Ohio. Its SC series reportedly forms sheet up to 0.120 in thick in areas up to 40 x 100 in. and draw depths to 10 in. at rates of 10-18 cycles/min. Cut-sheet machines typically run one to two parts a minute, says v.p. Mark Zelnick. The unit’s servo-electric chain mechanism has been modified to handle thicker sheet. The machine has a new press design as well.

Tamper-Evident Band Is Formed Into Lids

A tamper-evident band typically attached to a container lid through a secondary operation can now be thermoformed along with the lid in one step with a special machine from OMV-USA Inc., Genoa City, Wis. OMV and Nestech Machine Systems Inc., Hinesburg, Vt., developed the FC86, a device that perforates the thermoformed lid (typically of PP), creating a band of material that is torn off before the package is opened. A small pull-open tab remains on the lid when the band is removed. The lid also fits snugly onto the container when reclosing.

At NPE, the FC86 device was placed in-line with OMV’s D100 continuous thermoformer. OMV says the lids system has no impact on overall cycle times, does not require additional labor, and can be incorporated into a standard forming line. Standard filling/capping equipment can be used to press the lid with the tamper-evident band onto the container.

Forming System For IMD

The growing popularity of in-mold decorating with pre-printed sheet preforms is reflected in the new V Series vacuum former from ZMD International Inc., Long Beach, Calif. It reportedly forms sheet up to a 6-in. draw depth while maintaining registration of graphics to within 0.005 in.

At the show, the system was demonstrated with a new stress-relieved Lexan polycarbonate sheet in the True-To-Form (T2F) line from GE Plastics, Pittsfield, Mass. The 0.010-in. sheet was formed on ZMD’s new V222DHCG unit, which features a 2 x 2 ft forming area and PID-controlled, top and bottom ceramic ovens with 50 adjustable zones each.

Tooling Advances

A long-standing problem with trim-in-place tooling has been the compensation of the forming cavity each time the tool punch is sharpened. It is not practical to shave the forming cavity to be level with the punch, so instead the punches had to be shimmed, which is a relatively costly and delicate solution. Marbach Tool & Equipment of Elkhart, Ind., has developed a new system in which the forming insert and ejector base share a common shimming element. When the punch is sharpened, which reduces its height slightly, this shimming element is ground down by the same amount, so that both inserts and base level out accordingly.

International Thermoforming Systems (ITS), Yakima, Wash., rolled out a new steel-rule form-trim-stack device for blister packaging. The FTS 3040 can run PP, PET, and PVC, with 30 x 40 in. forming area, 5-in. depth of draw, and speeds up to 30 cycles/min. The trim station is adjustable on three axes. Other features include servo-electric chain-rail indexing, Opto-22 touchscreen control, and optional quick-change tooling package for 20-min changeovers.

ITS also developed a four-screw lip roller for PP cups that can churn out 200-cc cups at up to 75,000/hr. The screw rollers each have a heating and cooling section to soften, roll, and cool the product.

The firm also developed a new trim press featuring servo-electric positioning of the web. It runs at up to 110 cycles/min.

Metapor is an air-permeable aluminum used to make thermoforming tools that don’t need cooling channels. It is now offered in a lower porosity version and also a high-temperature version from one distributor, Edward D. Segen & Co. LLC, Shelton, Conn. New HD 100 AL grade has an average pore diameter of 0.0005 in., down from 0.0006 in. for the standard grade. Smaller pores are designed to impart a smoother surface to parts. BF 210 AL is a new grade that can handle mold temperatures up to 410 F, compared with 226 F for the earlier version.

Count and stack formed parts with a simple new counter and push-off stacker from Sencorp Systems Inc., Hyannis, Mass. The pneumatically operated unit can be slaved to the thermoformer. It has a steel-rule trim die and 30-min quick-change capability. At the show the machine counted and stacked 15-mm PVC deli containers at 18 cycles/min.

Welcome Windows Control

ZMD introduced Windows-based software control to its line of thermoformers. It replaces DOS-based control. Each machine comes programmed with detailed graphical drawings of the machine, a listing of general process parameters, and step-by-step instructions on how to set up and operate the machine for 13 different thermoforming processes, such as drape forming, billow forming, or straight vacuum forming. Set-ups can be saved and retrieved.

Related Content

Sustainable Materials is Focus of Thermoforming Exhibits at K 2022

Thermoforming equipment makers including WM, Kiefel, and OMV will showcase processing of recyclable and biobased materials.

Read MoreIngenuity Is Part of This Former’s Name, and in Its DNA

Plastic Ingenuity started in a garage in 1972 and through a commitment to developing best-in-class products stands today as one of the largest custom thermoformers in the world.

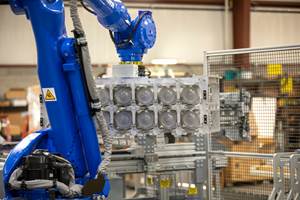

Read MoreAn Automation 'First' for Non-Servo-Eject Trim Presses

Compact, flexible and configurable robotic system is said to be the first to enable thermoformers to fully automate product handling after a non-servo trim press.

Read MoreUS Merchants Makes its Mark in Injection Molding

In less than a decade in injection molding, US Merchants has acquired hundreds of machines spread across facilities in California, Texas, Virginia and Arizona, with even more growth coming.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More

.png;maxWidth=300;quality=90)