Share

Read Next

Noryl started out as a miscible mixture of PPO, a high-performance but very hard-to-process engineering thermoplastic, and the commodity resin HIPS. Varying the blend proportions suits applications ranging from technical parts to heat-resistant thermoformed packaging like these trays. (Photos: SABIC)

As discussed in my last column, the engineering thermoplastic polyphenylene oxide (PPO) was a commercial reality by 1960. On paper, the polymer was a magnificent accomplishment, with thermal and mechanical properties that were unmatched at the time within the family of amorphous polymers. The material matched up favorably to high-performance polymers that were still 20 years in the future, such as polyethersulfone and polyetherimide. But the processing challenges and high levels of internal stress in the molded parts were substantial deterrents to commercial introduction of the material. The breakthrough came, as it often does, with an accidental discovery by someone working in the Selkirk, N.Y., facility of GE Plastics. I remember someone at the company sharing the name of this individual with me during a phone conversation in the early 1990s, but all I can recall from that conversation is a first name, Leon, and my research to find that person in the annals of the history of our industry has been unsuccessful.

The breakthrough was the observation that while purging a machine with high-impact polystyrene (HIPS), the melt mixture of HIPS and PPO appeared to be miscible. Further investigation showed this to be true and in a short period of time, an entire product line was created simply by varying the ratio of the two polymers. High-heat, high-performance grades emphasized the PPO ingredient, while lower-performing grades employed higher levels of HIPS. All of these grades exhibit a single glass transition that is characteristic of a miscible blend. In 1966, GE’s Noryl product line was commercialized (now a product of SABIC).

None of the Noryl grades could match the performance of pure PPO. To the extent that HIPS was added to the base polymer, the mechanical and thermal properties were reduced and even the highest-performing grades fell well short of what was theoretically achievable. But the materials were moldable. Anyone who processed the materials in the early days got a sense of how challenging the pure PPO must have been by observing the increases in melt temperature, mold temperature, and injection pressure required to successfully produce parts in the higher-performing grades. The butadiene rubber in HIPS also provided improvements in impact resistance, and this could be further enhanced by incorporating additional rubber.

The blends possess a very low level of polarity; the equilibrium moisture content values are typically 0.05-0.07% and even at saturation the materials absorb only 0.2-0.25%. This low polarity provides for excellent electrical insulating properties and very good dimensional stability in both dry and wet environments. The materials also exhibit excellent resistance to hydrolysis, which can result from simultaneous exposure to elevated temperature and humidity. Unlike polycarbonate, which can be degraded by hydrolysis during melt processing as well as in end use, the PPO/HIPS blends demonstrate neither problem. The high degree of aromatic character in the PPO backbone made creation of flame-retardant materials very feasible and the material also accepted fillers like glass fibers and talc. In addition, the materials have among the lowest densities of those products generally classified as engineering polymers. Later R&D has created alloys of PPO with nylon 66, polypropylene, and some thermoplastic elastomers.

PPO lends itself to blends with other resins such as PP. Shown here: Noryl PPX for painted auto exterior parts like bumper fascia.

Ironically, the fact that Noryl materials contained HIPS was a source of embarrassment in the early years of commercial introduction. The marketing and technical information on these materials referred to them as PPO blends and inquiries regarding what else was in the blend were usually not answered. If the information was shared, it was only verbally with the sheepish admission that the other material was a commodity resin. The reason for this was simple: GE Plastics cultivated an image as a provider of engineering polymers. With a catalog that included polycarbonate, phenolic, and PBT polyester, the admission that this material family contained HIPS was not consistent with the persona of high performance.

Today this is not considered to be a disqualifying secret, the material family has established its importance in the industry and other manufacturers have introduced competitive products. But the presence of butadiene rubber in the compounds helps account for a curious phenomenon that technical representatives at GE Plastics always warned processors about. They referred to it as “overdrying.” We were always warned not to “overdry” these materials because doing so would increase their melt viscosity, making it difficult or impossible to produce parts, especially if they contained thin sections. We were also warned that this process was irreversible. I witnessed this several times when molding parts with sealing surfaces that relied on faithful replication of features in the mold that involved a thin profile.

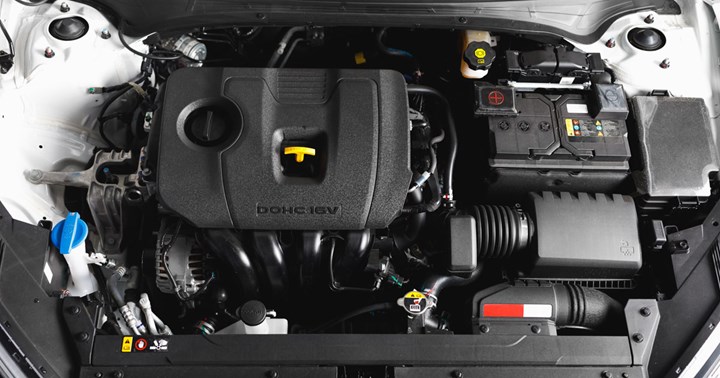

Noryl GTX is a blend of PPO and nylon, suited to under-hood automotive parts that can resist hot, humid conditions.

Unfortunately, the technical folks never properly explained the true nature of the problem. The increase in viscosity in these materials had nothing to do with a low moisture content. In fact, even undried PPO/HIPS blends seldom contain more than 0.07% moisture and only need to be dried down to about 0.04% in order to be processed satisfactorily. And unlike polycarbonate or polyester, if the material is processed without proper drying, the worst consequence is a cosmetic defect called splay or silver streaking. So, drying of PPO/HIPS alloys is a simple and low-risk task. I can recall watching a truck full of Noryl being unloaded in a driving rainstorm from a trailer. A leak in the trailer roof allowed the rain to soak the contents of several gaylords of the material. But once placed in a dryer, the material from these gaylords was low enough in moisture content to allow for processing within 45 minutes.

So, what is the cause of the increase in viscosity of a PPO/HIPS material that has been dried aggressively? It has to do with the butadiene rubber in the compound. Butadiene rubber contains what in chemistry we call an unsaturated site: Two of the four carbon atoms in each repeating unit of the molecule are connected by a double bond. This gives rise to the potential for mild crosslinking between the chains, which, in turn, increases melt viscosity irreversibly. But it has nothing to do with the moisture content of the material. If it did, the effect would be reversible. Dry polymers will re-absorb moisture. But you can’t reverse crosslinking of rubber.

It is unfortunate that GE’s technical-service people could not be straightforward with those of us charged with the responsibility of making good parts. It is perhaps even more unfortunate that while we have known for over 50 years that good parts can be molded from these materials with moisture contents of 0.04-0.05%, currently published data sheets dictate a moisture content of 0.02%. In addition, recommended drying temperatures are substantially higher than those needed for effectively removing what little moisture is present in these materials, thus encouraging the conditions that create processing problems.

In our next installment, we will discuss a very versatile thermoset elastomer that is making a comeback, especially in the worlds of medical devices and electronics, but has been around for almost 80 years.

Related Content

The Importance of Melt & Mold Temperature

Molders should realize how significantly process conditions can influence the final properties of the part.

Read MorePBT and PET Polyester: The Difference Crystallinity Makes

To properly understand the differences in performance between PET and PBT we need to compare apples to apples—the semi-crystalline forms of each polymer.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreHow to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection there are many variables that can dictate the best option.

Read MoreRead Next

How SABIC Developed a Prototype Solid-State Water Meter Made from Amorphous Noryl PPO to Make an Entry in that Sector

The company has demonstrated that GF Noryl can meet the required mechanical part performance level in injection molded complex parts to compete with incumbent thermoplastics and even brass.

Read MoreNew Grades Target Electric Vehicles

SABIC says the two new glass-fiber-reinforced grades of Noryl bring enhanced flame retardancy and impact strength to battery modules and housings in electric vehicles (EV).

Read MoreNylon/Modified PPE Resin for Demanding Automotive Applications in Hot and Humid Conditions

SABIC’s new Noryl GTX 9500 resin boasts superior dimensional stability, retaining improved balance of mechanical properties when exposed to heat and humidity in underhood and other applications.

Read More