SABIC Weighs In On Additive Manufacturing Materials

Overarching trend in plastics additive manufacturing: transition from a history of prototyping to a future of end-use part production.

Our February 2018 issue includes an article on SABIC (U.S. office in Houston) with a focus on the company’s development of an arsenal of specialty products based on its engineering resins that are optimized for a range of additive manufacturing (AM) processes (aka 3D printing) and which meet the end-use performance requirements of highly-regulated industries such as aerospace and healthcare.

SABIC has been working to develop materials for such additive processes as fused deposition modeling (FDM) and fused filament fabrication (FFF); selective laser sintering (SLS); and large format additive manufacturing (LFAM). The company has been active in this arena for more than a decade as a supplier of engineering resins to customers who produce filaments for FDM-type processes (which include FFF) and was best known as the supplier of Ultem PEI used by Stratasys, Eden Prairie, Minn. in its Fortus series of industrial FDM printers.

However, within the last three years, the company stepped up its efforts significantly and is now among the leaders in innovative material suppliers in the AM arena—including Solvay, Covestro, TOPAS Advanced Materials and specialty compounders A. Schulman and Elix Polymers, among others.

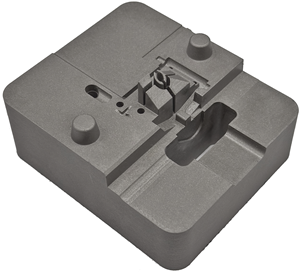

SABIC started to expand its footprint with its involvement in the emerging technology of LFAM. The company was a sponsor of a collaborative effort with Local Motors, Oak Ridge National Laboratory, and Cincinnati, Inc. that resulted in printing the Strati electric vehicle live at the 2014 IMTS show in Chicago.

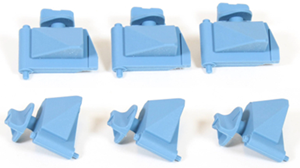

Last year, the company “shined” with the launch of: its initial portfolio of Thermocomp AM compounds for LFAM, a new generation of portfolio of filaments based on Ultem PEI, Cycolac ABS, and Lexan PC which reportedly offer the same composition as the company’s injection molding grades for FDM/FFF; and, a unique impact-modified PC filament, based on its Lexan EXL PC/siloxane copolymer with four times the impact strength of other PC filaments, also for FDM/FFF.

Key company sources told Plastics Technology that 2018 will be a very active year in terms of the variety of products planned for commercial launch.

For LFAM, there will be an expansion of the Thermocomp AM portfolio. Included are new compounds based on semi-crystalline resins such as PBT, nylon, PPS, and PEEK to address the industry’s needs for LFAM materials with improved chemical resistance and stiffness.

SABIC is also aiming to grow its involvement in SLS with new custom-made powder forms of engineering resins. Expect to see the launch of a unique PC powder that will allow fully amorphous parts to be produced. The company plans to expand this unique material and process technology to other amorphous resins.

For FDM/FFF, SABIC expects to launch Lexan PC and Ultem PEI healthcare-compliant filaments that meet ISO-10993 biocompatibility standards, as well as a series of support materials for each of its build materials.

These sources also weigh in on how they see the AM industry currently and their role in it, and how they envision it will evolve:

- How are you positioning yourself in the additive manufacturing space?

While we continue to be a supplier of resins to the additive manufacturing industry, we are also moving along the value chain to supply printable materials in their final form (e.g. filaments, powders) to help accelerate the adoption of additive manufacturing for end-use part production. We are also leveraging our materials expertise, plastics processing knowledge, and application development expertise to actively engage in collaborative efforts with experts from across the value chain to develop innovative solutions that address challenges facing the additive manufacturing industry.

- In which markets are you seeing the greatest growth opportunities?

Markets such as healthcare and aerospace, in which production volumes and the opportunities for personalization are well suited for additive manufacturing, continue to be the early adopters of the technology. Growth in other markets that have higher production volumes will be driven by improvements in process technology that can increase print speed and reduce overall part cost. In all cases, the availability of materials that are capable of meeting the application requirements for end-use parts is a key enabler of additive manufacturing for production use.

- What trends do you see happening in additive manufacturing and how is SABIC addressing these trends?

The overarching trend in plastics additive manufacturing is the transition from a history of prototyping to a future of end-use part production. To accelerate this transition, advancements are needed in a wide variety of areas including design software, material performance, process optimization, equipment reliability, part consistency, quality control, and secondary operations. SABIC is directly leveraging its expertise in material chemistry, formulation and printing process optimization to provide unique solutions designed specifically for additive manufacturing.

- How do you see the additive manufacturing industry evolving in the next three to five years?

We expect to see a continued focus on the industrialization of additive manufacturing. This will require the introduction of a wide variety of materials designed for use in additive manufacturing processes to meet the end-use application requirements of highly-regulated industries. We also expect to see the continued evolution of design software and process capabilities to enable repeatable production processes. To further enable the transition to production capabilities, it is also likely that new additive manufacturing processes will continue to be introduced which offer improved part performance and reduced production costs. The additive manufacturing ecosystem will also remain highly collaborative as alliances are built across the value chain to bring new products to the market as efficiently as possible and build sufficient production capacity to support the growing demand for production parts. We also see the intersection of additive manufacturing and composites as an area that will see increased focus in the near future.

- Is additive manufacturing growing faster in some regions versus others? What are the market drivers?

We see significant growth opportunities in all regions as OEMs strive to take advantage of the unique design capabilities and performance possibilities offered by additive manufacturing. A primary driver of the growth of additive technologies in the desire to transition away from prototyping applications and apply the technology to mass part production. While significant obstacles to implementing robust production processes remain, organizations such as America Makes—National Additive Manufacturing Innovation Cluster in Singapore are bringing together public and private sources of investment to target advancements in some of the most difficult and highest risk challenges on their additive manufacturing technology roadmaps. While there are some areas of localized expertise by region, the prevailing approach is a broad-based focus on enabling innovation across the entire global additive manufacturing value chain by encouraging collaboration among established companies, start-ups and universities.

Related Content

420 Stainless Steel Now Qualified With TrueShape 3D Printing Technology

NPE2024: Mantle's Additive Manufacturing Technology is Designed for Precision Tooling

Read MoreBusiness Slowing? There's Still Plenty of Stuff to Do

There are things you may have put off when you were occupied with shipping parts to customers. Maybe it’s time to put some of them on the front burner.

Read MoreMake Every Shot Count: Mold Simulation Maximizes Functional Parts From Printed Tooling

If a printed tool only has a finite number of shots in it, why waste any of them on process development?

Read MoreProduction Tool, Prototype Time

Mantle's metal 3D printing technology targeted toolmaking and injection molders and moldmakers are taking notice.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreRecycling Partners Collaborate to Eliminate Production Scrap Waste at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair will seek to recover and recycle 100% of the parts produced at the show.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More