Sustainable Lightweight PP Honeycomb Panel with Flax Fiber Composites

Belgium’s EconCore and Flaxco ‘pioneer’ use of flax in place of glass and carbon fiber composites in thermoplastic honeycomb.

Since 2018, we’ve been pretty much on top of reporting on the latest developments with the proprietary ThermHex thermoplastic honeycomb technology of Belgium’s EconCore. The company started out with packaging as its largest share of licensing dedicated to applications in this sector and, as such, the range of polymers used primarily included PP, PE, PS, PET, nylon, PC, and ABS, with some projects using PPS and PEI.

Just last year, we reported on how the company has been aiming its technology for use with higher-performing engineering resins such as the development of new honeycomb cores for laminated sandwich panels made with SABIC’s Noryl GTX resin, a PPE blend, and EconCore’s proprietary technology. This honeycomb core exhibits higher heat performance, better dimensional stability and lower water absorption compared to honeycomb structures made with traditional thermoplastics. These properties enable this core material to be used in demanding applications such as certain automotive, e-mobility and photovoltaic components.

A very recent innovation by EconCore and Belgium’s Flaxco (Division of Flipts & Dobbels NV) partnership is the development of a sustainable lightweight honeycomb panel with flax fiber composites to replace glass and carbon fiber materials. Flaxco has 150 years of experience in flax weaving, used in a range of applications including clothing, upholstery and decoration. This has evolved into manufacturing flax fibers for the composites industry, typically found in semi-finished products such as sandwich panels. In 2020 Flaxco approached EconCore suggesting combination of thermoplastic honeycomb technology with Flaxco’s flax fiber technology.

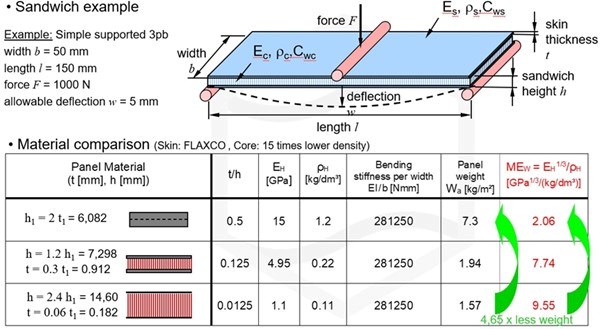

The PP honeycomb material produced by EconCore offers a high-performance-to-weight ratio along with efficient energy absorption. This is achieved through the materials synonymous honeycomb shaped hollow cells which support sandwich sheets to provide levels of high rigidity with minimal weight. Pioneering the use of flax with honeycomb technology, the partnership sees Flaxco’s flax fabric composite skins combined with EconCore PP core to produce sandwich panels.

Sandwich cores require surface layers, like the neatly woven layers that Flaxco has the means to create, in order to generate high stiffness. Once created the panels can be thermoformed thanks to their thermoplastic properties. This is typically done by means of short cycle compression molding. Achieving a product with well-balanced characteristics, required pre-pregs of 0.5 mm/0.02 in. to 1mm/0.39 in. thickness to be used. By optimizing flax technology with the PP honeycomb core, Flaxco is able to achieve much higher levels of rigidity.

Flax is a 100% natural fiber that produces lower CO2 levels than competitor materials including glass and carbon fibers, an increasingly important element within the automotive industry. Moreover, research and testing are already underway for the material to find its place within the sports industry.With high levels of cost efficiency compared to more conventional materials, the new Flaxco composite is expected to be the material of choice in a number of applications, especially those requiring dimensional stability. The new material aims to not only be used in new markets and applications but also replace non-sustainable materials already in use.

Said EconCore CEO Jochen Pflug, “For new product developments sustainable materials have become a key requirement. Within the automotive industry in particular, suppliers seek sustainable materials which lower their CO2 footprint. Flaxco’s natural flax fiber PP composites are an ideal combination with our PP honeycomb cores to achieve a sustainable material that retains high levels of performance. The production costs of thick monolithic laminates are high because many layers need to be combined, our honeycombs increase the stiffness and strength but require only a minimal amount of material in two thin surface layers.”

The partnership between Flaxco and EconCore has greatly benefited by the Belgium locations of their facilities, allowing for a local supply chain, essential when one crisis after the other affects the transportation chains, from the Coronavirus pandemic to the recent raw material shortages.

Said Flaxco’s innovation & business development manager Ludwig Ryckebosch, “It was a match made in heaven. EconCore’s PP honeycomb has been incredibly easy to work with. Its lightweight properties meant that it was the perfect choice to combine with our technology to develop flax fiber composite material.”

The partners expect the flax composite material to have commercial applications across many industries, especially automotive interiors and computer casings. With sustainability being a key focus for companies across the globe, this all-new flax composite’s ability to be recycled without compromising on performance is expected to play its role in reducing carbon emissions.

Related Content

Prices of All Five Commodity Resins Drop

Factors include slowed demand, more than ample supplier inventories, and lower feedstock costs.

Read MoreFundamentals of Polyethylene – Part 6: PE Performance

Don’t assume you know everything there is to know about PE because it’s been around so long. Here is yet another example of how the performance of PE is influenced by molecular weight and density.

Read MoreThe Fundamentals of Polyethylene – Part 1: The Basics

You would think we’d know all there is to know about a material that was commercialized 80 years ago. Not so for polyethylene. Let’s start by brushing up on the basics.

Read MorePolyethylene Fundamentals – Part 4: Failed HDPE Case Study

Injection molders of small fuel tanks learned the hard way that a very small difference in density — 0.6% — could make a large difference in PE stress-crack resistance.

Read MoreRead Next

Why (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read More