Will Oil Price Changes Continue to Be a Key In PE Pricing?

Oil prices just rallied above the $50/bbl mark; this, while PE prices continued to decline this month.

Oil prices just rallied above the $50/bbl mark; this, while PE prices continued to decline this month.

Within the last four to five years, crude oil prices have been one of the key drivers influencing PE pricing. Plunging oil prices this year helped keep PE prices relatively stable until September when suppliers successfully implemented a 5ȼ/lb increase; this owing to tightened supply at the time.

In fact, the September PE price was the highest since January 2015, when crude oil first dropped to $45/bbl from $90/bbl. Also that month, domestic commodity PE film processors followed suit by announcing price hikes of 6%.

At that time, I spoke with Mike Burns, Resin Technology, Inc.'s (RTi) v.p. of client services for PE, and he cautioned on likely competition from imported finished PE goods that could emerge following this action. Burns emphasized the influence of the plastic bag market on overall PE pricing by noting these key factors:

Nearly 40% of PE sold is used for film applications: retail bags, garbage bags, food packaging, construction, medical supplies, etc.

Cost to produce a retail bag, grocery bag or can liner in China/Southeast Asia and deliver to a North American city is 25ȼ/lb over the cost of resin.

Cost to produce a retail bag, grocery bag or can liner in North America and deliver to a North American city is also 25ȼ/lb over the cost of resin.

Note: In 2015 and 2016, the average cost to produce and deliver PE pellet derived from oil/naphtha was near 45ȼ/lb; for that same time frame North America’s average cost to produce and deliver PE pellet from shale gas was 30ȼ/lb).

North American PE suppliers need to keep film production in North America.

When the price delta exceeds 10%, retailers call China/Southeast Asia.

Although Burns, and other industry pros, initially thought PE suppliers would aim to hold on to that 5ȼ/lb margin gain through year’s end, by the October-November time frame, things were looking quite different. Industry dynamics, including suppliers’ growing inventories, sluggish export demand, some softness in domestic demand, and lower prices abroad hampered that aim.

Burns had noted that “something had to give”. He pointed out that PE contract prices were now 5ȼ above what they should be. At the same time, spot prices were as much as 10ȼ/lb lower vs. a more typical 5-7ȼ less than contract prices. Ditto for export prices which were 15ȼ lower vs. a more typical 7-10ȼ less than contract prices.

By early November, PE suppliers offered price concessions of 3 cents/lb, and some signaled further drops for December on the order of 2-5ȼ/lb, with 2-3ȼ, a more realistic expectation, ventured Burns. Speaking with Burns on December 1, regarding what might happen in January, he noted that if crude oil prices moved up to an expected $50/bbl, that may stop any further PE decreases, but will not result in increases. Only if oil prices rise beyond $55/bbl, will shale gas prices also move up, as will PE prices, he ventured.

Which bring us to Monday, Dec. 12, when nearly a dozen non-OPEC producers agreed to reduce their crude oil output in support of OPEC’s efforts to prop up prices. Prices jumped to $53.95/bbl, with some analysts talking about a $60/bbl or more emerging.

However, the U.S. Energy Information Administration (EIA), in its latest Short-Term Energy Outlook stated that the resurgence of U.S. shale will undermine the OPEC-fueled price rally, putting a cap on oil prices at about $50/bbl through 2017. The EIA also is doubtful on how much OPEC will actually follow through on its deal.

“The extent to which the announced plans will be carried out and actually reduce supply below levels that would have occurred in their absence remains uncertain.” The agency ventures that an above $50/bbl rally will simply serve to revive U.S. shale drilling, which will “encourage a return to supply growth in U.S. tight oil more quickly than expected.”

Back to RTI’s Burns, whose 2017 forecast is based on RTi’s naphtha resin cost model; namely, naphtha has a close10:1 ratio with oil—it moves very close to oil price movements. Every $2/bbl change in oil prices equals approximately 1ȼ/lb in the cost to make a pellet from naphtha. As such, every $10/bbl price movement above or below $50/bbl will increase or decrease the PE price 4-5ȼ/lb.

Related Content

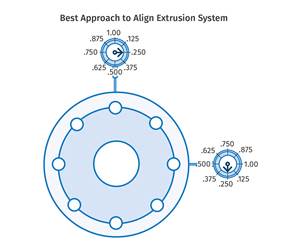

Extruder Alignment: Important, but Only Half the Equation

The other half? Aligning and supporting downstream equipment. Here are best practices.

Read MoreHow to Estimate and Control Head Pressure

You rightfully worry about melt temperature, but don’t overlook head pressure, because the two are closely linked and will influence line performance.

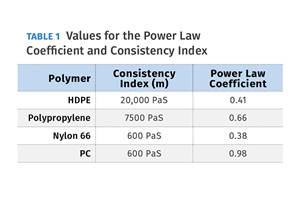

Read MoreThe Importance of Viscosity in Melting

The calculations required to determine the right melt temperature for each polymer are complicated. Knowing the power-law coefficient and the consistency index of the polymer you run might prove useful.

Read MoreThe Importance of Barrel Heat and Melt Temperature

Barrel temperature may impact melting in the case of very small extruders running very slowly. Otherwise, melting is mainly the result of shear heating of the polymer.

Read MoreRead Next

Processor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

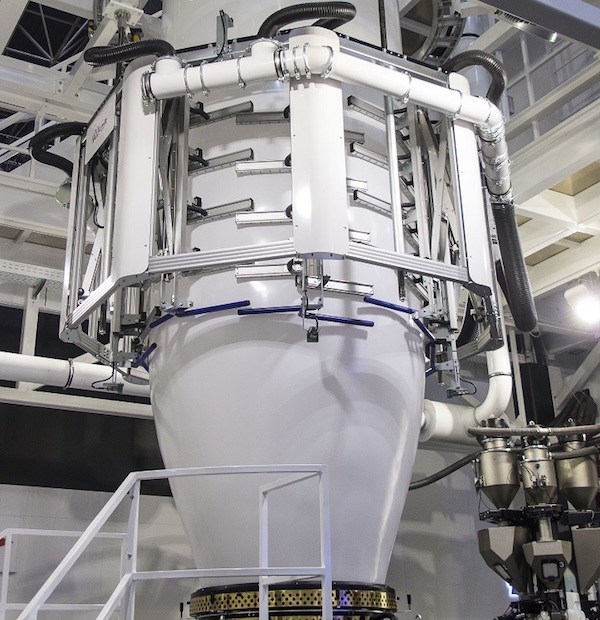

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More

.png;maxWidth=300;quality=90)