The Value of 20 Bits of Data

With these 20 bits of data, toolrooms can drastically lower the cost of keeping molds running and improve mold reliability and tooling life while reducing breakdowns and molding better parts.

The idea behind data usage in mold maintenance is to use historical bits of information to guide us like a crystal ball as an indicator of the future. That can provide great opportunities for improved efficiency and change the way you do maintenance. So, in the spirit of opportunity, let me introduce to you 20 bits of data. These 20 bits are not only habit forming, but they will transform a weak, reactionary, “fire-fighting” maintenance culture into one that is stronger, more aggressive, and pro-active towards continuous improvement and company profit building.

These 20 bits of data can be found in the cracks and crevices of your current work-order systems. Useless on their own, together they form an insightful and unique picture of not only how a mold performs in the press but what corrective actions, tooling, and labor hours were required to keep it there.

With these 20 bits of data, toolrooms can drastically lower the cost of keeping molds running and improve mold reliability and tooling life while reducing breakdowns and molding better parts.

SO WHO NEEDS THIS DATA?

Anyone who wants to produce quality parts efficiently and on time. As those in charge of keeping molds running, our job is to devise a plan to eliminate or reduce the frequency of the issues that cost companies money and bog down continuous improvement. It’s as simple as that.

Engineers want to know performance and maintenance history so they can build better molds. Quality assurance wants better quality parts and fewer customer issues. Production wants to mold parts on time. Repair technicians want to be better informed and make better decisions and improve their skills. Shareholders and owners want to make more money and grow the business. It would seem 20 bits is a small price to pay for so much opportunity.

Mold maintenance, like every department, needs goals. Real progress can be measured. When toolroom managers are not challenged with certain KPIs (Key Performance Indicators), chances are they will never be able to set nor achieve goals. Thus the opportunity to build a stronger, safer, and more efficient repair shop is wasted.

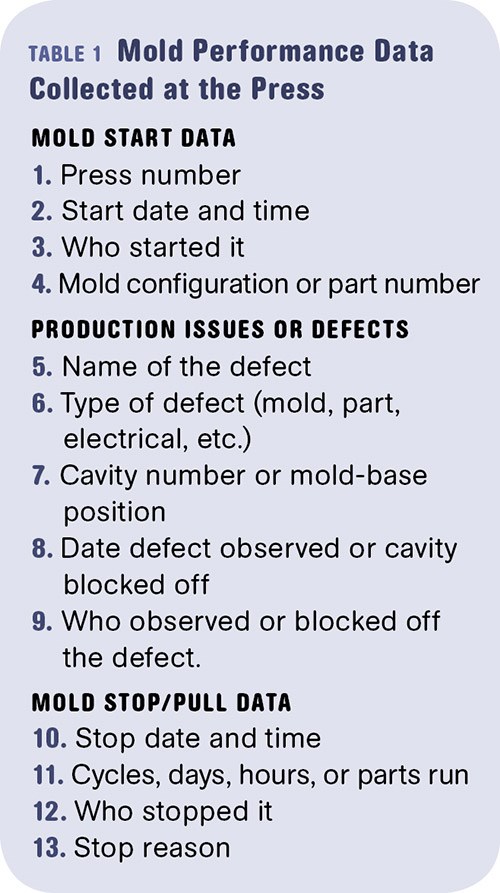

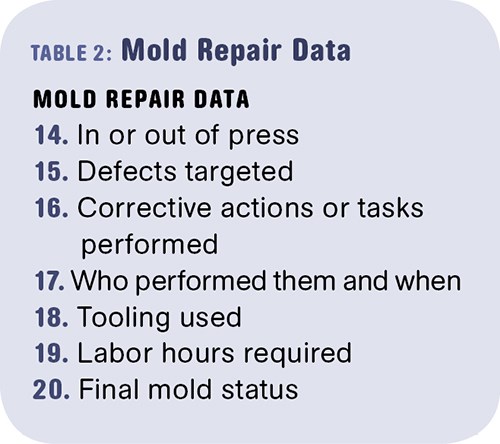

To set goals based on measureable data, our 20 data bits need to be recorded in standard terms and collected as shown in the accompanying charts. Our 20 bits are divided into two categories. The first 13 bits involve production information taken at the press during a mold’s run time (Table 1). The final seven bits concern what was done to the mold when it came out of the press–in other words, mold repair data (Table 2).

THERE IS AN ORDER TO THINGS

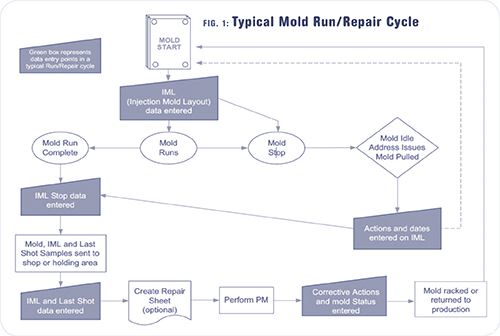

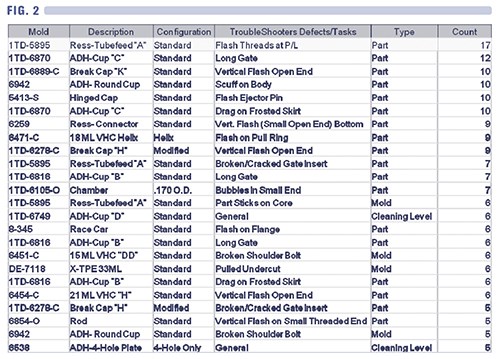

The 20 data bits are best collected at specific intervals during a mold’s run/repair cycle. The run/repair chart (Fig. 1) shows where the 20 bits should be collected. The report shows information that is actionable and based on the 20 bits. A sample report (Fig. 2) shows information that is actionable, but it is based on only some of the 20 bits. This report shows us what defect was suffered most often over a specific period. Many reports like this can be constructed from the 20 bits.

Look at your data-collection methods and talk to your IT guy about corralling the 20 bits from your data system. Have him provide these to you in a spreadsheet format that allows you to sort, filter, and analyze the 20 bits as shown in Fig. 2. It doesn’t take a gazillion-dollar electronic maintenance system or years to develop and train your employees on how to use the information. It only takes just 20 little bits of data that work and play well together, and provide opportunity.

Related Content

How to Get Rid of Bubbles in Injection Molding

First find out if they are the result of trapped gas or a vacuum void. Then follow these steps to get rid of them.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreUnderstanding Strain-Rate Sensitivity In Polymers

Material behavior is fundamentally determined by the equivalence of time and temperature. But that principle tends to be lost on processors and designers. Here’s some guidance.

Read MoreHow Much L/D Do You Really Need?

Just like selecting the extruder size and drive combination, the L/D should be carefully evaluated.

Read MoreRead Next

Processor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More

.png;maxWidth=300;quality=90)