Vacuum Take-off Boxes

.jpg)

A vacuum take-off box is mounted under each silo, surge bin and drying hopper in a central system. They are also used under drying hoppers for stand-alone dryers. They are designed to provide material exits to 1-5 destinations.

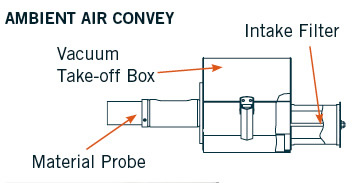

Material falls from the source container into the VTB where it stays until this material is needed at a destination. A signal at the destination causes the vacuum stream to open and the vacuum pulls material out of the VTB to the desired destination. A probe with a pellet screen and adjustable collar that modulates the airflow controls the amount of ambient air flowing with the material to the destination. Material needs sufficient airflow to be conveyed so the probe valve (see illustration at right) should always be at least 50% open.

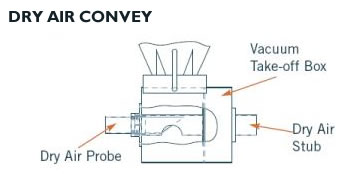

Vacuum takeoff boxes are usually supplied with one or more cartridge filters for ambient air conveying (bottom left). If dry air conveying (bottom right) is being utilized, the cartridge filter(s) are replaced with a dry air stub which connects to a dry air manifold coming from the dryer and a dry air probe is used that does not allow ambient air to contact the material.