Additives: Additive Masterbatch Boosts rPET Performance

Aquadye Fibers’ new Nylester masterbatch for compounders brings rPET performance to nylon 6 equivalent.

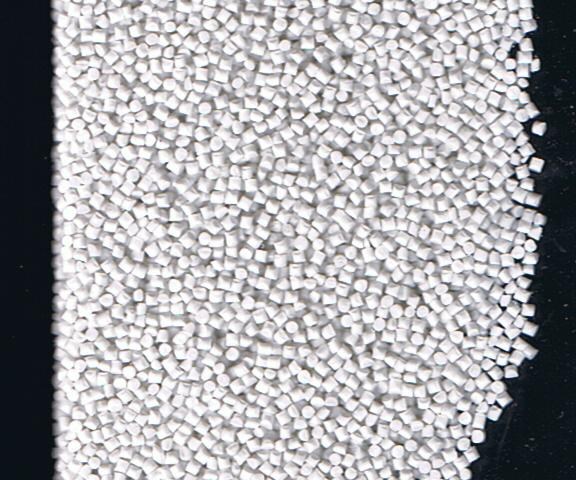

A proprietary pelletized additive masterbatch from Aquadye Fibers, Danville, Ky., is said to allow compounders to elevate recycled PET (rPET) performance equivalent to that of nylon 6. The addition of 10% of new Nylester to rPET during pellet extrusion, allows compounders to expand the use of recycled PET to both injection molded and extrusion applications, ranging from packaging to gears to automotive underhood applications.

Meanwhile, the finished compound of 10% Nylester masterbatch and rPET or virgin PET is called Nylester6, signifying they perform like nylon 6. Nylester6 reportedly is economical to produce. For example, rPET chips cost around 45¢/lb, 10% Nylester costs 35¢/lb, resulting in the total raw material cost of only 80¢/lb.

Efficient processing of Nylester requires that it be dried at 185 F for two hours before use. Moisture must be less than 0.5%. Compounders can use their typical extrusion temperatures to produce Nylester6 pellets. Nylester masterbatch is currently available in 25-lb to 50-lb sample packages. Commercial quantities are offered in a 1000-lb package. Nylester masterbatch is priced at $3.50/lb, and the product is shipped from Dalton, Ga.

Related Content

-

Graphene Masterbatches for Flexible and Rigid Polyolefin Packaging and Beyond

Brazilian start-up Gerdau Graphene joins a growing group of graphene additives suppliers with a focus on boosting properties of large volume commodity thermoplastics.

-

Gerdau Graphene Launches “First” Graphene-Enhanced PE Additive Masterbatch for Extruded Packaging and More

The company has also partnered with conglomerate Sumitomo Corp. for distribution of its graphene-enhanced masterbatches in Japan.

-

Surface-Activating Primer for Polyolefins and Fluoropolymers

XlynX Materials’ PlastiLynx is designed for use with low-surface-energy polymers for improved bonding and printing.

.png;maxWidth=300;quality=90)