Injection Molding Machine Line Launched

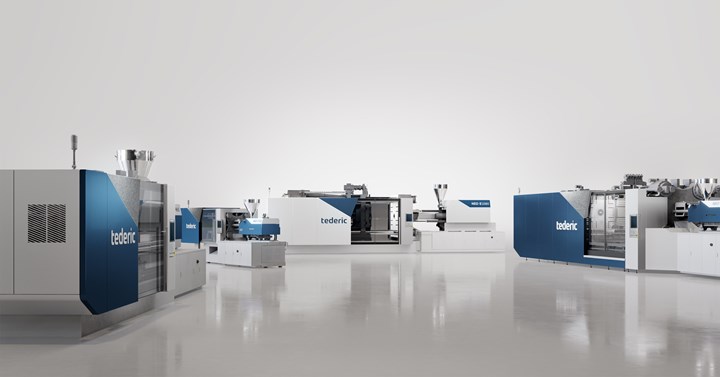

Available in North America in late 2021, the NEO Series from Tederic debuted at Chinaplas 2021 with six lines.

Tederic Machinery Co. (U.S. office in Palmetto, Fla.) introduced the NEO series of injection molding machines at Chinaplas 2021, including all-electric, hybrid, multi-material, and 2-platen models. Available in China immediately, NEO will be rolled out to export markets over the next six months, with North American availability coming in late 2021.

All machines feature a Keba control, with the option for a 12-, 15-, or 21-in. touchscreen, with enhanced multi-touch configurations available on the larger screens. The control supports OPC UA and Modbus data protocols and features free programming capabilities for special process requirements.

Able to achieve maximum pressure in 28 msec, Tederic’s NEOs feature a new generation of servo-pumps with high response speeds that can save from 30% to 80% in energy consumption compared to traditional hydraulics. The machine guarding has been completely redesigned for safe, practical use and to conform to local safety standards where the machines are sold.

Six Lines Launched In Total

Tederic says the new machine series includes six distinct lines: NEO · T, NEO · E, NEO · Ec, NEO · H, NEO · Mv and NEO · Ms.

The NEO · T servo-toggle machines range in clamp force from 90 to 4000 tons. New features include larger tie bar spacing, greater mold height and a special clamp-braking system to improve mold positioning accuracy.

The NEO · E all-electric machines range in size from 55 to 460 tons and feature larger tie-bar spacing, NSK linear bearing for platen guidance, and a standard 15-in. touch screen, as well as the latest generation of motors and drives with DC bus technology. Injection speeds up to 500 mm/sec are available with pressure accuracy reportedly down to less than 1 bar.

The NEO · Ec hybrid-electric machines range in size from 168 to 1088 tons, with injection, screw rotation and clamping all electro-mechanically driven. There is an integrated power pack with a servo-pump to power the ejectors, carriage and core pulls. The carriage has twin hydraulic pistons, and the moving platen features linear bearing guidance. Here too the 15-in. touch screen and latest generation motors and drives with DC bus technology are standard. The NEO · Ec is available with injection speeds up to 250 mm/sec.

The NEO · H two-platen servo-pump machines are initially available in the 680 to 2700 ton range, with that eventually extending through 4000 tons. The line offers larger tie bar spacing, enhanced mold daylight, and a special clamp-braking system to improve mold-positioning accuracy. A 15-in. touch screen and motors and drives with DC bus technology are standard, and available options include electric screw drive, tie bar extraction, and extended daylight with mold side-loading.

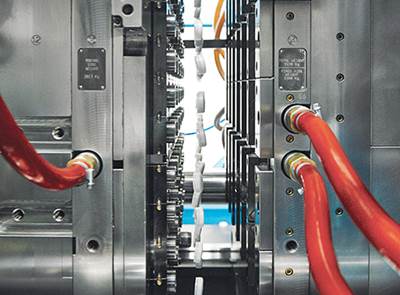

The NEO · Mv range of multi-material machines is equipped with the Spinsure-V vertical rotary platen integrated into the moving platen casting. These servo-driven rotary platens offer a full range of utility connection options. Wide-platen toggle machines ranging from 170 to 810 tons and two-platen machines from 880 to 1920 tons can be configured with up to five independently controlled injection units. These units can be positioned in parallel, at an angle to, perpendicular from or vertical to the main machine axis. Both hydraulic and electric injection units are available.

Finally, the NEO · Ms special range of multi-material machines range in clamp force from 880 to 1920 tons. These also are equipped with the Spinsure-H horizontal rotary table positioned between the fixed and moving platens and used to rotate the center section of a stack mold. The machine has two opposing injection units as standard, with the secondary unit riding behind the moving platen. Additional injection units can be added as required. The rotary table movement and positioning are independently controlled, allowing for a range of mold designs and complex applications.

Tederic’s new NEO series of injection molding machines includes six different lines.

Related Content

Word Games: What’s a ‘Hybrid’?

Any molder will tell you there’s a difference in working with electric vs. hydraulic drives. Servohydraulic is still hydraulic; a hybrid machine is something different. Imprecise use of terms causes needless confusion.

Read MoreInjection Compression Molding as Alternative to Thermoforming

Arburg will show its all-electric Allrounder 720 A press utilizing injection compression molding to create thin-wall IML cups from PP.

Read MoreAdaptive, Automatic Process Control for Injection Molding

Sumitomo (SHI) Demag says its activeMeltControl for all new IntElect 2 machines can automatically compensate for shot-weight variations.

Read MoreCompact Hybrid Injection Molding Machine Launched

Sumitomo Heavy Industries Ltd. (SHI) has introduced the iM18E, promising the smallest footprint in 20-ton machines.

Read MoreRead Next

INJECTION MOLDING AT NPE: Presses, Robots & Cell Automation

Everything molders need to compete in markets from automotive to medical was on display in Orlando. Besides a huge number of new machine models, there was emphasis on cell integration and automation.

Read MoreINJECTION MOLDING AT NPE: Molding Exhibits Show Off Cell Integration with Multiple Processes & Operations

If you’re interested in lightweight composites, IML, LSR, multi-shot, inmold assembly, barrier coinjection, micromolding, variotherm molding, foams, energy-saving presses, robots, hot runners, and tooling—they’re all here in force.

Read More