INJECTION MOLDING: New Electric Press Series Geared for Mid-Sized Molding

Highly spec'ed presses handle bigger, heavier molds for mid-sized automotive and other parts.

A “substantially different” mid-sized all-electric machine series was introduced last month by Sumitomo (SHI) Demag. Eight model sizes from 247 to 562 U.S. tons are said to offer significantly enhanced specifications together with “exclusive advanced technologies” that allow bigger parts and molds to run on smaller machines with all-electric precision, speed, and energy efficiency. One particular target for the new SEEV-A line is automotive, where molders have adopted electric machines for smaller precision parts but less so for mid-sized and larger parts, according to Sumitomo Demag.

Besides being able to carry larger, heavier, and more complex molds, SEEV-A machines handle higher injection requirements that would typically run on hybrid or hydraulic presses. “This machine series will end any perception of mid-sized all-electrics being lightweight or unable to handle bigger, heavier molds,” says John F. Martich II, v.p. and chief operating officer of Sumitomo Demag’s U.S. operations, based in Strongsville, Ohio.

SEEV-A models are said to “meet or beat” the specs of competitors’ next-larger-size all-electrics:

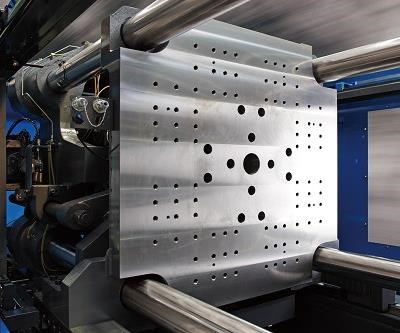

• Tiebar spacing is at least 8% larger in the transverse direction and 15% or more in the vertical direction than the preceding SE-HDZ series. Not only is this reportedly the largest among machines of the same class, but the square tiebar spacing allows molds to be loaded from the side.

• Bushing-free tiebars keep the mold area clean and free of grease.

• Mold-opening stroke is 25 mm wider than the SE-HDZ and mold-thickness range can be extended optionally by 100 to 200 mm, depending on model size.

• Ejector stroke is 220 mm for all models and is said to be the longest among machines of this class.

• Stronger, more rigid frame can carry molds 22% heavier, on average, than the SE-HDZ, and deflection has been reduced 50%.

• New linear guide system is standard, ensuring parallelism and smooth movement of heavy molds.

• Improved Double Center Press Platen design further reduces surface-pressure inconsistencies across the mold by 15%.

• Clamp Force Feedback Control automatically compensates for thermal expansion of the mold to avoid excessive clamp pressure that can constrict venting and add wear on molds.

• Exceptionally fast clamp speeds up to 56.6 in./sec (1438 mm/sec).

• Larger injection units and higher-duty motors and drives are available, capable of higher and longer peak injection pressures. Hold pressures, up to 33,360 psi, exactly match injection pressures, and all models can deliver full power for up to 40% of the cycle.

• Higher injection speed is optionally available to 220 mm/sec for thin-wall products, vs. 160 mm/sec standard.

• Greater choice of screw diameters, up to 90 mm.

• High-contact-force nozzle-touch system with selectable settings of 4.5, 5.6, and 6.7 tons, is equal to a hydraulic or hybrid machine, the company states.

• Enhanced NC-10 controller offers wider viewing angle and increased touchscreen sensitivity.

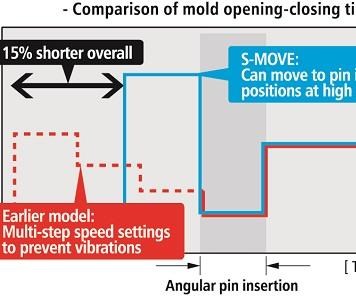

In addition, the SEEV-A series offers several exclusive Sumitomo Demag advanced control technologies. A new feature called S-Move replaces multi-step mold-open/close speed settings with an optimized speed profile that is is smoother in acceleration/deceleration, with 50% less vibration, and also 15% faster. This, together with fast clamp movements, reportedly can shorten cycle times significantly.

Other existing control features from Sumitomo’s S-Molding repertoire include Flow Front Control (FFC), which releases the compressed melt flow front like a spring to provide complete and balanced filling with reduced injection pressure. Minimum Clamping Molding (MCM) automatically reduces clamp-force requirements to optimize venting while preventing flash. And Simple Process Setting (SPS) provides fast, guided setup.

This new machine series will be represented at the K 2016 show in Dusseldorf, Germany, Oct. 19-26.

Related Content

US Merchants Makes its Mark in Injection Molding

In less than a decade in injection molding, US Merchants has acquired hundreds of machines spread across facilities in California, Texas, Virginia and Arizona, with even more growth coming.

Read MoreIn Sustainable Packaging, the Word is ‘Monomaterial’

In both flexible and rigid packaging, the trend is to replace multimaterial laminates, coextrusions and “composites” with single-material structures, usually based on PE or PP. Nonpackaging applications are following suit.

Read MoreHow to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

Read MoreFoam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

Read MoreRead Next

How Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More

.png;maxWidth=300;quality=90)