More Sustainable Two-Component Overmolding

Swedish compounders HEXPOL TPE AB and Polykemi AB have collaborated on a 2K sustainable development project for consumer products.

HEXPOL TPE and Polykemi have collaborated on material combinations for multicomponent injection molding based on the resins’ properties and sustainability qualities. The companies’ goals included demonstrating the possibilities in reducing the product carbon footprint, while increasing recyclability and optimizing adhesion.

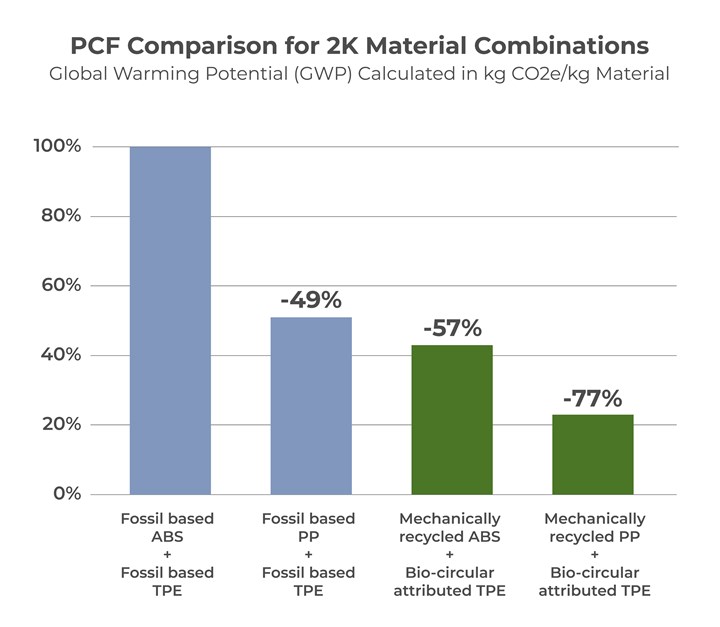

The compounders documented the cradle-to-gate Product Carbon Footprints (PCF) and Global Warming Potential (GWP) per kg of material. The PCF data shows that switching from a combination using fossil fuel based ABS from Polykemi, that is overmolded with a fossil fuel based TPE from HEXPOL TPE, to a recycled PP and TPE with bio-circular attributed content, can result in a 77% reduction in carbon dioxide emissions. The companies say this combination can also provide end-of-life and recycling compatibility advantages.

Combinations using mechanically recycled ABS with bio-circular attributed TPE were also tested, resulting in a 57% reduction in carbon dioxide emissions compared to the fully fossil-based equivalents. The TPE has bio-circular attributed content via the mass balance principle from 2nd generation feedstocks.

HEXPOL TPE and Polykemi have collaborated to determine maximum carbon reduction possibilities for overmolding PP with TPE.

Photo Credit: HEXPOL TPE and Polykemi

Related Content

-

Servo-Hydraulic Machine Range Adds Multicomponent Models

Absolute Haitian says the Mars and Jupiter Lines will now offer multicomponent models, complementing the 2K all-electric Zhafir.

-

Multicomponent Mold Combines Capping and Unscrewing Functions for Pharma Closure

Braunform says its patented RotaricE² mold, which will mold Luer lock pharmaceutical closures in Arburg’s K 2022 booth, allows the use of one tool and one machine, versus two, while eliminating post-mold assembly.

-

Mold, Hot Runner, Digitization and Process Monitoring at K 2022

The Barnes Group’s Molding Solutions division companies will highlight new mold and hot runner technologies at its own booth and at several machinery partners during K 2022.

.png;maxWidth=970;quality=90)