Partnership Augments LSR Molding Simulation

SIGMA Engineering and Momentive Performance Materials announced a cooperation to optimize material data for silicone elastomers to make LSR molding simulation more reliable.

In an agreement between a provider of LSR injection molding simulation and one of the top manufacturers of silicone and silicone derivatives, SIGMA Engineering GmbH and Momentive Performance Materials are collaborating on an effort to use more precise material data to create more accurate simulation of LSR injection molding.

The companies note that the more precise the material data and understanding of the material, the better the predictions made by the simulation, adding that applying standardized laboratory values for the material properties can’t fully describe the complex behavior of components.

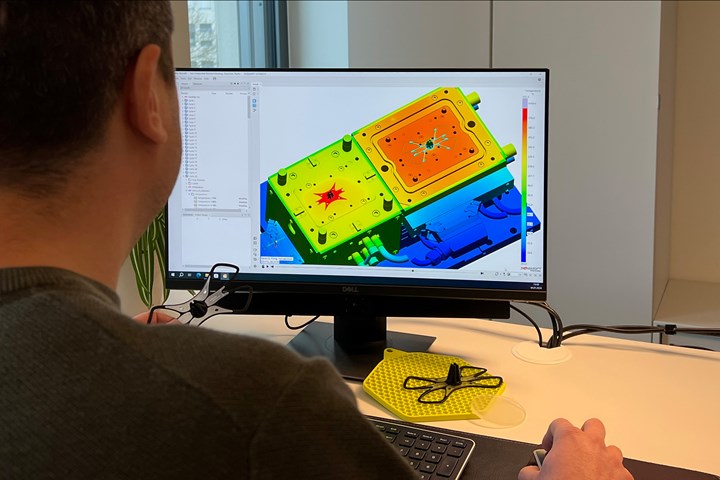

The companies say data from real injection molding processing is needed to refine and calibrate the material data and improve the reliability of the simulation results. Since 1998, SIGMA Engineering has offered its simulation software Sigmasoft Virtual Molding to the plastics processing sector. The program combines a part’s 3D geometry with its tooling and temperature control system, while also integrating the parameters of the production process for more accurate simulations. Sigmasoft Virtual Molding has multiple process-specific models including 3D simulation of LSR molding.

Sigmasoft Virtual Molding will apply silicone material data from Momentive to improve LSR injection molding simulation. Photo Credit: Sigmasoft

Related Content

-

LSR Advances in Dispensing, Tooling and Automation

At Fakuma 2023, Sumitomo (SHI) Demag’s LSR injection molding machines showcased advances from itself and partners Reinhardt-Technik, Rico and Sepro.

-

Fakuma 2023: Wittmann Battenfeld Expands All-Electric Line, Direct-Current Capabilities

Wittmann Battenfeld will introduce the new EcoPower B8X injection molding machine line and show direct current as an energy source for a concept machine that will power its own robot.

-

Finding a Niche in LSR Tooling

20 years ago, southern California moldmaker M.R. Mold & Engineering pivoted to LSR tooling, giving it a foothold in a challenging but growing market.