Pipe Extruder, Die Heads Plus a Cobot Demo

Milacron to debut updated extruder, control and die head packages. Also demonstrating how cobots can be used to automate pipe production.

Milacron is debuting a new extruder, as well as new die heads for pipe. It will also demonstraate why cobots are not just for molding applications.

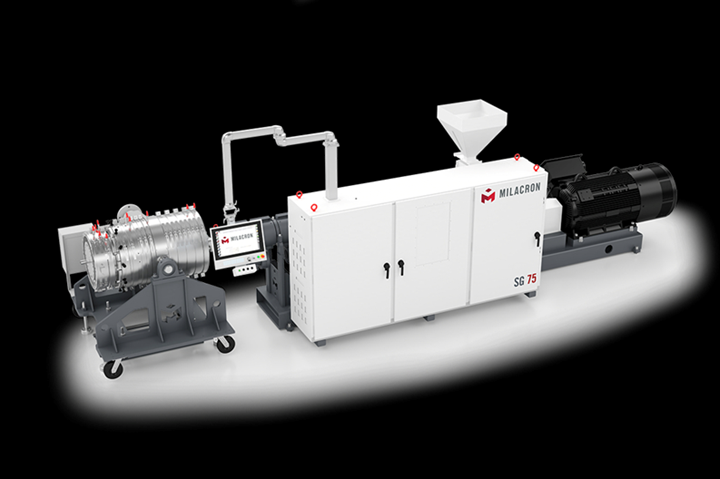

On the extruder side, its SG (for single grooved) 75-mm single-screw machine now features insulated shrouds to reduce heat loss versus a previous noninsulated design. The shroud design provides easier maintenance of the heaters and blowers than the previous design. The machine’s controller has a 21-in. high-definition screen. The touchscreen works like modern smart phones with minimal use buttons. The controller is capable of full line integration.

There are two new die heads on display. The PH die heads have been flow modeled to ensure the head design is optimized for flow to optimize wall control and minimize color changeovers. A range of polyolefin pipe sizes can be made from a single head. The PH is currently available for pipe sizes ranges from ½-in. to 48 in. and outputs up to 2.2 tons/hr.

Milacron’s MPH die head family is designed specifically to produce PVC pipe. Features include quick tip changes and easy-to-change dies that reduce the time it takes to change over the die to a different pipe size. It is currently available for pipe sizes ranging from 1/2-in. to 30 in. and outputs up to 2 tons/hr.

A newly upgraded Genca D3030 die head includes features that are operator friendly, such as an easy-adjust die centering feature, a patent-pending design for the application of stripes, and an optimized flow design for balance wall control.

Milacron is also featuring a cobot robot cell, utilizing a Fanuc CRX-10iA/L series unit to simulate how such a machine can be used to automate production of a PVC pipe line. This operating cell is without guarding panels due to the collaborative robot safeties built into the CRX Series Robot Line.

Related Content

-

How to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

-

In Sustainable Packaging, the Word is ‘Monomaterial’

In both flexible and rigid packaging, the trend is to replace multimaterial laminates, coextrusions and “composites” with single-material structures, usually based on PE or PP. Nonpackaging applications are following suit.

-

Pregis Performance Flexibles: In the ‘Wow’ Business

Pregis went big and bold with investment in a brand-new, state-of-the-art plant and spent big on expanding an existing facility. High-tech lines, well-known leadership and a commitment to sustainability are bringing the “wow” factor to blown film.