Milacron

Plastics Machinery Americas

4165 Half Acre Rd.

Batavia, OH 45103 US

513-536-2073

milacron.com

IS THIS YOUR COMPANY?

Video Gallery

Milacron M-500

The M-500 machine cell features a Mold-Masters hot runner and Kurz in-mold decoration technology for custom textures and ...

M-Series Co-Injection

A pioneer in the plastics processing industry, and one of the largest North American-based OEMs, Milacron is set to showcase its ...

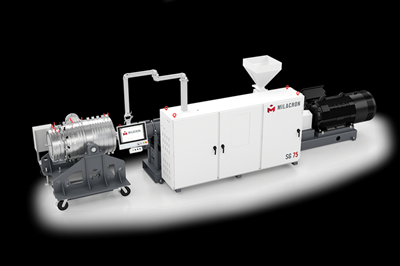

Milacron’s SG75

Milacron's SG75 extrusion pipeline exhibit can't be missed spanning more than 85'across the center of the booth and featuring a ...

Q-Series 170

The Milacron Q-170 is a reliable, general-purpose, high-performance machine in a durable package within the low to ...

As Seen On Plastics Technology

Milacron Supplies the Following Products

- Accumulators (Melt)

- Assembly Robots and EOAT

- Automation/Systems Integration

- Blenders (non-intensive)

- Business Services for Plastics (Finance, Insurance, Leasing)

- Chillers

- Closed-loop Process Control Systems

- Coextrusion Dies, Feedblocks

- Compression/Transfer Molds

- Conveying Equipment (pneumatic and Mechanical)

- Conveyors (parts-handling)

- Cooling Towers

- Custom Machine Builders

- Cylinders (plasticating) and Liners

- Desiccant for Dryers

- Dewpoint Monitors/Moisture Analyzers

- Drives and Motors

- Dryers for Resins

- Equipment Cleaning Services

- Extrusion Dies

- Feeders

- Flow Monitoring/Control Devices (for Liquids)

- General Purpose Robots and EOAT

- Granulators

- Heat Exchangers

- Hopper Loaders

- Hoppers, Bins, Tanks

- Hot Runner Components

- Hot-water or Oil-circulating Temperature Controllers

- Hydraulic Components and Systems

- Hydraulic Oil

- Hydraulic Oil Filtering/Reclaim Service

- Injection Molding Machines

- Injection Molding Non-return Valves

- Injection Molding Nozzles

- Injection Molds

- Knives for Granulators, Pelletizers

- Labeling Equipment--In-Mold

- Level Sensors and Controls

- Liquid Mixers

- Machine Alignment Services

- Machine Installation Services

- Machine Maintenance Services

- Machine Monitoring/Alarm Systems

- Machinery Rebuilding

- Maintenance Management Systems

- Metal Detectors, Separators

- Mold Components

- Motion or Position Controls

- Mounts for Machines

- Multiple-screw Extruders

- Part or Sprue Removal Robots and EOAT

- Pelletizers

- Pipe Take-off Systems

- Plastic Lumber Extrusion/Molding Systems

- Platens

- Preheaters for Materials

- Pressure Controllers, Monitors

- Pressure Sensors, Transducers

- Product & Tool Design, Analysis Software (CAD/CAM/CAE)

- Profiles, Tubing, Hose Take-off Systems

- Rebuilt Screws or Barrels

- Scheduling, MRP, Production and Inventory Management Systems

- Scrap-reclaim Systems

- Scrap-reclaim Systems--Sorting/Fractionating Systems

- Screw Conversion Kits

- Screw Design/Analysis Software

- Screw Tips

- Screws (Plasticating)

- Sheet Take-off Systems

- Silos

- Single-screw Extruders

- SPC, SQC Systems

- Speed, Drive Controls

- Stacking, Packing Equipment

- Structural Foam Machines (for Thermoplastics)

- Temperature Controllers, Monitors

- Temperature Pyrometers, Sensors, Thermocouples

- Timers

- Training Programs in Plastics

- Troubleshooting, Problem Solving Systems

- Used Machinery

- Vacuum Pumps

- Valves, Gates, Diverters

- Vision Systems

- Weigh Scales

Trade Names Offered by Milacron

- WearTechnology

- Ferromatik Milacron Europe

- Q-Series

- PowerPAK

- Cincinnati Milacron Extrusion

- M-Powered

- Roboshot

Editorial, News, and Products

-

Pipe Extruder, Die Heads Plus a Cobot Demo

Milacron to debut updated extruder, control and die head packages. Also demonstrating how cobots can be used to automate pipe production.

-

Faster Top-Entry Model Among 19 Robots in Orlando

NPE2024: Sepro Group will introduce the newest S5-25 Speed robot, promising 63% faster acceleration, as one of 19 robots on display at its booth and partner booths at the show.

-

Midtonnage Hybrid Range With Compact Footprint Launches

NPE2024: Milacron has the global launch of its new M-Series injection molding machine line featuring a large clamp stroke as standard in a line of midtonnage, compact-footprint machines.

-

NPE2024 Features Medical Industry Sessions

Learn about trends in sustainability, materials, collaboration and more at the NPE2024 Medical Industry Sessions.

-

Mack Expands Injection Molding Capacity, Staff

The custom molder and contract manufacturer added a 240-ton Milacron Electric Roboshot E240 and a 125-ton Milacron Q110 Hybrid press to its facility in Cavendish, Vermont.

-

Inside the Florida Recycler Taking on NPE’s 100% Scrap Reuse Goal

Hundreds of tons of demonstration products will be created this week. Commercial Plastics Recycling strives to recycle ALL of it.

-

Fakuma 2023: Sepro Introduces Its Fastest Top-Entry Robot, Integrative Controller

The concept ThundeRbot enters and exits the mold with parts in 0.79 second, while the Sepro Visual+ controls all the peripheral equipment in the show cell.

-

Mack Molding Adding Five New Injection Molding Machines

The three Cincinnati Milacron’s and two Wittmann Battenfeld’s, ranging in size from 1433 to 2500 tons, are destined for Mack’s Arlington, Vt. headquarters and Inman, S.C. facilities.

-

Medical Molder Boasts Showpiece Material-Handling System

Flex Manchester is so proud of its new, elaborate drying/conveying system that it greets visitors front and center on their way to view the cleanroom molding floor.

-

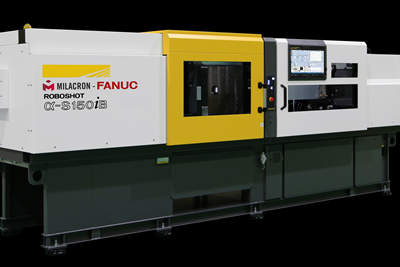

All-Electric Injection Molding Machine Range Expanded

Milacron is now offering the Fanuc Roboshot Alpha-SiB, continuing Milacron’s partnership with Fanuc in the Americas and expanding on the previous Alpha-SiA series.

-

Profile Processor Combines People & Technology to Fuel Growth

Custom Profile started almost 30 years ago with one employee and one extruder, and has evolved into an international processing business with three plants serving a variety of markets. And plans are in the works to expand further.

-

New Technology Opens a Predictive Window Onto Screw Wear

Despite their integral role in transforming pellets fed through the hopper into parts ejected from the mold, visibility into the performance, health and efficiency of screws is difficult to discern for many reasons, not the least of which being the fact they’re located inside a barrel.

-

PlastiCert Adds Two Molding Machines

The Lewiston, Minn. custom molder has added two new Cincinnati Milacron injection molding machines as it pursues its capital investment plan.

-

20 Good Things to Come Out of 2020—Part 4

Good news was there if you knew where to look for it—in the pages of Plastics Technology magazine or right here on our website. Here’s a review of headlines you can feel good about.

-

Milacron Joins Organization for Machine Automation and Control (OMAC)

Along with its IIoT partner, ei3, Milacron is now part of a working group to establish best practices for remote access methods.

-

Injection Molding: Milacron Expands Industry 4.0 Platform

In a series of webinars, plastics machinery manufacturer Milacron revealed details of its M-Powered suite of Industry 4.0 tools, including expanding functionalities.

-

Milacron Announces Rental Options for New Machinery

Plastics processing machinery supplier Milacron introduced a new rental option for its equipment via an exclusive financing partner, Equipment Finance Group (EFG), granting emergency capacity to serve Covid-19 projects.

-

New Global Standard Aims to Harmonize Injection Molding Machine Safety

ISO 20430—the first international safety standard for plastics and rubber machinery—was published after more than seven years of collaboration by roughly 40 experts from machine makers, associations, and health and safety organizations hailing from 13 countries.

-

Milacron Renews Partnership With Barr for Screw Technology

Milacron has extended its exclusive partnership to offer Robert Barr Inc. designed screws on new Milacron injection molding machines or as aftermarket add-on to existing presses.

-

Tenere Shapes Market Niche Where Metal and Plastics Meet

Joining metal and plastics to target some of today’s most dynamic industries, contract manufacturer Tenere reinvented itself—and its customer list—in 2016.

-

Injection Molding: Faster, Smarter, More Efficient Machines Tackle Sustainable Molding at K 2019

Blazing speed plus shrinking energy consumption supported the “green” theme at the big show. Smarter controls and growing connectivity were another key focus.

-

The New Uniloy Plans Numerous Machine Developments

Starting with barrier coinjection at K 2019, Uniloy plans new blow molding machinery developments across four product lines.

-

Moving Toward ‘Autonomous Molding’ with a Uniform-Low-Pressure Process

A new low-pressure injection molding process has aroused interest among molders and machine suppliers. In his second article on iMFLUX, the inventor of the process explains how it is evolving to support the overall industry goal of self-correcting molding processes that can compensate for common causes of variation to maintain consistent part quality.

-

Speed and Flexibility Help Molder, Moldmaker Fill a Niche in Product Development

Quotes in hours, parts and molds in days—Xcentric Mold & Engineering brings prototype speed to production molding and moldmaking.

-

K 2019 Preview: Molds and More at the Messe

Here’s news to look for in molds, mold components, hot runners and controls at the giant K fair in October.

-

Invasion of the Giant Cleanrooms!

Fed by growing demand for medical molding, cleanrooms keep getting bigger and bigger.

-

K 2019 Preview: Injection Molding Goes for the ‘Green’

‘Circular Economy’ joins Industry 4.0 as common themes of injection molding exhibits in Düsseldorf.

-

Hillenbrand Inc. to Acquire Milacron Holdings

Milacron joins Coperion, Rotex, and other industrial holdings under the Hillenbrand umbrella.

-

Uniloy Completes Separation from Milacron

Brian Marston remains in charge of the new Uniloy, Inc.

-

Injection Molding: Sepro Robot Controls Integrated With Fanuc Roboshot Machines

Program and operate the robot from the press controller.

-

Milacron to Exit Blow Molding Machinery

Milacron intends to divest the blow molding machinery business as not meeting its profitability goals.

-

Profile Processor Looks Beyond Windows and Doors

Intek Plastics intends to maintain a leadership position in its core fenestration business. At the same time, it’s on a mission to leverage its expertise in materials know-how, engineering, technology and customer collaboration to become a force in other profile extrusion markets as well.

-

Injection Molding: Upgraded Servohydraulic Toggle Line Is Milacron’s New ‘Global’ Design

New general-purpose toggle presses have upgraded clamp specs.

-

Get Better Control of Your LSR Molding

Better control of LSR mixing/dosing and cold-runner valve-gate injection, as well as improved mold-design capabilities are highlighted at Molding 2019 Conference.

-

New Process Eliminates Resin Variations as a Quality Variable

At Molding 2019, learn about the latest enhancements to the iMFLUX low-pressure injection molding process, including Auto Viscosity Adjust to compensate for resin variations.

-

Headlines from Fakuma 2018

Integrating a special low-pressure process into machine controls; novel shop-floor quality-inspection technology; MES systems from machine and controls vendors; and sophisticated in-mold decorating.

-

Milacron Is First to Integrate iMFLUX into Machine Controller

Integrating iMFLUX low-pressure process into machine controls is a more economical route to faster cycles and improved part quality.

-

Milacron Demonstrates iMFLUX Low-Pressure Injection Molding at Fakuma Show

Milacron is first to demonstrate this innovative low-pressure process at a trade show.

-

Pellet to Gate Control: The Value of a Holistic View of Melt Management

Molders tend to think about the elements of a melt-delivery system, from screw to hot-runner gate, in isolation from each other. But taking an integrated view of the whole system can have big consequences for cycle time, part quality, scrap rates, and energy consumption.

-

NPE2018 Tooling: Molds Join the Industry 4.0 Conversation

At NPE2018, multiple companies displayed mold monitors that would allow the tool in an injection molding cell to “talk” to other equipment and remote computers.

-

NPE2018 Auxiliaries: A Path to Industry 4.0 Emerges

Industry 4.0 dominated the news in auxiliary equipment at the show, but many questions remain for both suppliers and processors.

-

NPE Wrap-Up: News in Primary Machinery, Part 1

Rounding up details from the Big Show not previously reported in all our other coverage, here’s more news in injection and blow molding, extrusion and compounding. Next month, we’ll conclude with recycling/scrap reclaim, robots, tooling, auxiliary equipment, materials and additives.

-

News Highlights from NPE2018

Developments in Industry 4.0, multi-layer preform molding, automation, LSR processing, and PP were among the major newsbreakers at May’s show. And one film processor finalized purchases of 13 new lines.

-

‘Smart Data’: The Rise of the ‘Dashboards’

For North American plastics processors, NPE2018 offered the broadest exposure yet to the bundle of trends and technologies known as Industry 4.0 or the Industrial Internet of Things (IIOT).

-

NPE2018 New Technology Focus: Pipe, Profile, Tubing

Check out what’s new in pipe, profile and tubing extrusion.

-

NPE2018 New Technology Focus: All-Electrics Multiply in Blow Molding

All-electric shuttles and injection-blow machines continue to proliferate.

-

NPE2018 New Technology Focus: LSR in the Spotlight

LSR remains a popular topic, visible at numerous molding demos at the show.

-

NPE2018 New Technology Focus: Foam Fascination

A new physical foaming process and a significant enhancement of the MuCell process attract attention at the show.

-

NPE2018 New Technology Focus: Single-Screw Extruders

What's new at the plastics industry's big trade show in single-screw extruders.

-

Milacron Is ‘Going Big’ at NPE2018

Milacron is emphasizing large-tonnage injection presses, enhanced customer service to maximize their uptime, and speed—both speedy delivery of parts and suppies, and products that speed up production for their customers.

-

Plastics Hall of Fame: 10 Inspiring Stories

Last evening, at the Linda W. Chapin Theatre, the Plastics Academy inducted 10 new members into the Plastics Hall of Fame. Meet these outstanding individuals with remarkable stories. Each one teaches a lesson of hard work and creative thinking.

-

NPE2018 New Technology Focus: The ‘4.0’ Revolution

Injection and blow molding and robot suppliers are making Industry 4.0 the most prevalent theme of the show.

-

Ira Boots: Automation and Innovation for Growth

A strong believer in automation as a driver for growth, new Plastics Hall of Fame member Ira Boots has contributed to build what Berry Global is now and to give direction to Milacron.

-

NPE2018 New Technology Focus: Multicomponent Injection and Blow Molding Demos

Multicolor and multimaterial molding includes composites, LSR, and even barrier preforms and bottles at this show.

-

Extrusion/Compounding at NPE2018: More…More…More!

More speed, flexibility and robustness. Across a gamut of extrusion applications, machine builders are introducing new machinery, components, and systems to dramatically raise the bar on productivity.

-

Rapid Heat/Cool Molding with Induction Heating Achieves ‘High Definition’ Mold-Surface Replication

At least three exhibits will show the benefits of rapid heat/cool molding with Roctool’s induction heating.

-

New Foaming Technology for Thin-Wall Parts

Trexel’s new MuCell P-Series nitrogen dosing equipment enables greater lightweighting of thin-wall packaging than ever possible before.

-

Resin-Specific Injection Screws & LSR Conversion Kit

Zeiger Industries shows a Plug-n-Play LSR conversion kit and screws designed and built of special materials for specific engineering resins, especially reinforced grades.

-

Solving the Puzzle of LSR Molding

See Milacron’s Enhanced LSR Package at work molding 16 puzzle pieces.

-

New ‘Workhorse’ Toggle Presses from Milacron

Quantum servo-hydraulic toggle line offers clamping forces from 125 to 610 tons.

-

Injection-Blow Molding Multi-Layer Barrier Bottles

Kortec hot-runner technology and an auxiliary injector convert a standard machine to three-layer co-injection blow molding.

-

Single-Screw Extruder for a Wide Range of Applications

Flexible machine for pipe, profile, tubing, sheet, and more.

-

Really Big Machines Dominate Milacron Booth

The largest machine at this NPE—or any NPE to date—is Milacron’s new 2250-ton Cincinnati machine. Not to mention the massive platen of a 6600-tonner now under construction, also on view.

-

TOOLING: New Developments in Tooling For In-Mold Assembly

Multiple rotating plates index in and out of the mold to produce parts with up to six materials.

-

Decoding ‘Industry 4.0’

The biggest splash at NPE will come from the wave of technological innovation and futuristic enthusiasm known variously as Industry 4.0 or the Smart Factory or the Internet of Things.

-

VIDEO: Plastimagen Marches On

Only 49 days removed from a devastating earthquake and with the possibility of sweeping changes to a key trade deal looming, Plastimagen 2017 in Mexico City plowed forward.

-

Milacron’s First Klear Cans Hit Store Shelves

Clear, coinjected cans of PP and EVOH hold fruit pieces.

-

How Parkway Makes Stock Jars Into a Custom Business

This family firm distinguishes itself in a commodity market by offering numerous ways to customize its stock products.

-

Injection Molding: Industry 4.0 Advances at Fakuma 2017

At October’s Fakuma fair in Germany, several injection machine suppliers will showcase their progress toward Industry 4.0 connectivity.

-

Two Molders Investing in Medical Market

Currier Plastics and NPI/Medical invest in clean rooms; molding and blow molding machines; testing equipment and more.

-

K 2016: Connectivity & Collaboration in Robotics & Automation

Besides a handful of new robots and pickers, the big themes were modular ‘plug-and-play’ automation, Industry 4.0 connectivity, easier programming, and safer collaboration with human workers.

-

K 2016 Injection Molding: Rapid Pace of Development

Servo drives dominate. Other trends include multitouch screens, adding materials data to process controls, and Industry 4.0 connectivity.

-

What Blow Molders Say About All-Electric Machines

They are well established in Europe, but molders in North America are just beginning to come around to all-electrics’ improved performance, maintenance, cleanliness, and—yes— energy efficiency. Here’s first-hand testimony, from the U.S. and abroad.

-

Novel Hot-Runner Technology Borrows From Flat-Die Extrusion

Nozzles with a wide slit fill at lower temperature and pressure.

-

Milacron’s Industry 4.0 Initiative on Display at K 2016

Transforming the mold from a "dumb" component to an active element of the Smart Cell in the Smart Factory.

-

Smart Tool, Electric Tool

The old gray mold ain’t what she used to be. Or won’t be for long, if recent trends hold up.

-

Milacron Launches “eSTORE”

Online ordering of spare parts, supplies, and whole machines and systems.

-

What’s Brewing in Technology to Make Coffee Pods

With more than 9 billion of them sold last year alone, the prospect of selling high-output production systems to make single-serve coffee pods must be enough to make a machine builder’s mouth water.

-

Milacron to Show Wide Range of New Technologies at K 2016 Milacron

New developments in injection and blow molding, extrusion, hot runners, and tooling will be featured.

-

Milacron Coinjection Tech Approved For Fruit Cans & Recyclable Coffee Pods

First-to-market clear plastic cans wil arrive early next year.

-

MOLDING 2016: New Approaches to Processing, Tooling & QA

The largest-ever annual Molding Conference included newsworthy technical presentations on a variety of injection molding topics. Here’s a selection.

-

Ahead of the Curve in Recycling

A pioneer in recycling milk bottles built a thriving business in plastic lumber, but blow molding with PCR has proved a longer, harder road to success.

-

Ten Intriguing Injection Molding Technologies of 2015

I know I’m leaving myself wide open on this one. I was asked, “What are the 10 most interesting injection molding technologies of 2015?” I should have pleaded eggnog hangover and politely declined.

-

Clear, Retortable Plastic Can Made from Extruded Tube

Coextruded PP/EVOH tube with double-seamed metal ends.

-

Prototype to Production: NPI/Medical Is Quick-Turn Artist

New name, same focus: From 1 part to millions, a new-product development manufacturer for over 45 years.

-

Fakuma Show News: Hot Runners & Tooling

Hot-runner nozzles, manifolds, and controls, as well as other mold components and a new tooling concept made their debut in Friedrichshafen.

-

Coinjected Plastic Can Passes Key Food-Safety Tests

Double-seamed metal lid passes standard leakage tests at up to 121 C.

-

Down in the Valley, Profiles Grow

Valley Extrusions carves niche in tight-tolerance, short-run tubing and profiles.

-

Highlights of Fakuma 2015

A selection of the hottest news and molding trends at this “little brother” to the K Show.

-

“Winning With the Lifecycle Approach”

Milacron reimagines its role in the plastics industry.

-

Funny Looking Robots

Super-high-speed pick-and-place units made their debut at a plastics show.

-

Eastman Explores Processing of Tritan Copolyester For Small, Multicavity Medical Parts

A sophisticated 32-cavity mold and all-electric press are being used to define the process window and critical mold and part design criteria.

-

Tooling at NPE: Valve Gates & Multi-Tips Top the News

There’s no letup in development of sophisticated hot-runner nozzles and controls. Here’s news in these and other tooling products at the show.

-

EXTRUSION AND COMPOUNDING NPE: Flexibility, Speed and Quality

Extrusion processors need more—of everything—to compete. And suppliers responded in force in Orlando.

-

INJECTION MOLDING AT NPE: Presses, Robots & Cell Automation

Everything molders need to compete in markets from automotive to medical was on display in Orlando. Besides a huge number of new machine models, there was emphasis on cell integration and automation.

-

News Highlights from NPE2015

Here’s a first look at new technology in materials, auxiliaries, and all types of processes.

-

Slideshow: The sights of NPE2015

Relive NPE2015 through photos taken by the Plastics Technology staff.

-

At NPE: 3D Printed Molds

UV photopolymer produces short-run cavity inserts.

-

At NPE: Coinjection, LSR/TP Overmolding, PET Preforms & New Two-Platen Presses

There's plenty new at the largest booth at the show.

-

INJECTION MOLDING AT NPE: Molding Exhibits Show Off Cell Integration with Multiple Processes & Operations

If you’re interested in lightweight composites, IML, LSR, multi-shot, inmold assembly, barrier coinjection, micromolding, variotherm molding, foams, energy-saving presses, robots, hot runners, and tooling—they’re all here in force.

-

EXTRUSION AND COMPOUNDING AT NPE: The Word Is ‘More’

As in speed, power, quality, flexibility, layers, and efficiency. Those are the trends across all extrusion processes.

-

A Challenger Tackles Coinjection For Barrier PET Preforms

Barrier PET containers for beverages, sauces, and other sensitive products become more cost-effective through more efficient use of expensive barrier resins.

-

More Details on Husky’s Barrier Coinjection Debut

New challenger promises big savings through more uniform barrier-resin distribution.

-

Two New Alliances in Microcellular Foams

Trexel has licensed Milacron to supply turnkey MuCell systems for injection and blow molding, and joined with Lubrizol to develop a new TPU foam technology.

-

Overcome Typical Challenges in LSR Molding

Here’s a quick overview of basic mold and machine factors behind common LSR molding headaches and how to avoid them.

-

TOOLING: Mold Simulation Software Gains Speed & New Functionality

Enhancements in simulating conformal cooling, hot runners, MuCell foaming, shrink/warp, and fiber reinforcements.

-

Teel Plastics: Where Science, Tech, Quality and Innovation Meet

This family-owned custom profile and tubing business controls its own destiny by controlling, well, everything.

-

2013 was good for N.A. equipment suppliers; Can 2014 Overcome a Slow Start?

The North American plastics equipment market saved its best for last in 2013, delivering shipments valued at $335.1 million in the fourth quarter—the best three-month stretch of the year and up 3% from the previous quarter. Will that momentum hold in 2014, however?

-

A Piece of History Comes Home

Almost 50 years and 40,000 machines after it started making them, Milacron now has the third injection molding machine it ever built back in its possession and on display.

-

Milacron Buys Kortec Coinjection Technology

Kortec plus Mold-Masters equals a powerhouse in coinjection.

-

Custom Structural Foam: A Small But Thriving Niche

How to succeed in the small but busy world of custom structural foam? Maximize your pounds per hour and use robots.

-

Milacron acquires Kortec building its coinjection portfolio

Milacron is building an impressive injection technology portfolio that will give it greater reach into packaging markets.

-

Milacron reestablishes West Coast presence with new tech center

Milacron has a new West Coast home in Irvine, Calif., formally opening its new High Impact Technical (HIT) Center, with more "HITs" planned for the future.

-

Milacron Expands Aftermarket Business—Again

Milacron LLC, Cincinnati, recently completed the purchase of Industrial Machine Sales, Inc. (IMSI) and its sister company, Precise Plastics Machinery (PPM), both of Southlake, Texas.

-

Milacron Adds to Its Aftermarket Family

Milacron LLC recently completed the purchase of Industrial Machine Sales, Inc. (IMSI) and its sister company, Precise Plastics Machinery (PPM), both of Southlake, Texas.

-

Extrusion/Compounding at K 2013: Having It All

Extrusion processors no longer need to chose among speed, quality, and flexibility, based on exhibits at K 2013.

-

Injection Molding at K 2013: Doing More with Less

More productivity with less energy consumption and capital investment; more operations in the machine or manufacturing cell with less time, labor, energy, and capital—these were the common themes of injection molding exhibits at October’s K 2013 show.

-

New Hybrid Machine Platform Focused on Customization, Integration, Energy Savings

After five years of product development behind the scenes, Athena Automation is ready for its close-up.

-

Extreme Molding’s Mantra: ‘Find Your Niche and Stick to It’

For a small custom injection molder competing in today’s global market, Lynn Momrow-Zielinski has two pieces of advice: 1) Develop a business plan and stick to it. 2) Find a technical and/or market niche and stick to that, too.

-

Sustainable Medical Molding: For Nypro, It’s Good Business

“Why worry about sustainability?” asks Ed Cathey, controller of Nypro’s Mebane, N.C., injection molding plant.

-

Larger, All-Purpose, All-Electric Machines Debut from Milacron

As reported in our Keeping Up section last month, Milacron LLC invited Plastics Technology to its Batavia, Ohio, headquarters for an exclusive preview of its new Elektron line of all-electric injection presses ahead of their official debut at Milacron’s open house Apr. 24-25.

-

Exclusive: Milacron Launches New All-Electric Press Series

At press time last month, Milacron LLC, Batavia, Ohio, gave Plastics Technology an advance look at a line of all-electric machines being launched globally this month.

-

Moldmaker Explores New LSR Molding Technologies

Can liquid silicone rubber (LSR ) be overmolded onto polypropylene?

-

Making the Value Connection In Proprietary Molding

“We make components that go into other devices.

-

This Molder Wants Only the Tough Jobs

Need someone to injection mold fluoropolymers, highly filled PEE K, Torlon, or Ultem in complex shapes, tight tolerances, multiple cavities, and high volumes? “We love doing this,” says Tom Mendel, president of Performance Plastics Ltd. (PPL) in Cincinnati. “We’re not for everybody.

-

NPE: New Machines Exhibit Sophisticated Molding Demos

More speed, more power, more precision, and more automated functions accomplished in and out of the mold. That’s exactly what injection machinery suppliers were offering at NPE2012.

-

Injection Molding: Speed, Automation & Integration

Hot buttons at the show will be multi-component molding, in-mold labeling/decorating (IML/IMD), in-mold assembly, medical molding, liquid silicone rubber (LSR), micro-molding, and high-speed packaging.

-

Get Better at Multi-Material Molding

Since each multi-material application is unique, there’s no standard best method for success. Each molding solution must be tailored to meet the needs of the final product.

-

More Hydraulic Presses Get Energy-Saving Servo Drives

Injection molders who want to save energy costs have a growing number of alternatives.

-

Automation & Waste Reduction: A Medical Molder's Efficiency

Vision Technical Molding in Manchester, Conn., doesn’t believe in standing still.

-

Why Use All Electric Injection Molding Machines?

All electric injection molding machines turn injection molding into a predictable, robotic operation.

-

EXTRUSION & COMPOUNDING: Five-Layer Film Structures Set to Supplant Three Layers?

In blown film, equipment and material suppliers have come together to push five-layer technology into non-barrier applications previously held by three-layer films.

-

INJECTION MOLDING: Automation and Integration At K Show

There were new presses of all stripes aplenty at K 2010, but the “wow” factor was supplied by automated work cells and integrated manu-facturing systems performing multiple operations before, during, and after molding.

-

Progressive Injection Molder Pioneers in Thermoforming IML

When you’re a successful injection molder with more than 40 years under your belt and more than 50 presses producing 1.8 billion containers and lids for food-packaging containers annually, what do you do when you feel the time is right to expand?

-

Extrusion at NPE 2003

NPE is typically a competitive display of the biggest, most dramatic equipment machine builders can muster.

-

Hybrid Injection Clamps The Best of Both Worlds?

In between all-electric and hydraulic-powered injection machines, a new species of hybrid clamp has emerged. Advocates say it combines the best qualities of electric servos and hydraulics without their disadvantages.

-

New Presses at Fakuma Show Focus on Energy & Performance

Beltless direct-drive electric machines and upgraded electric/hydraulic hybrids were introduced at the 20th Fakuma trade exhibition in Friedrichshafen, Germany, last month.

-

NPE 2009 Wrap-Up: New Machinery for Extrusion and Compounding

Extrusion machinery at the June NPE show in Chicago showed inventive ways to get more out of your floorspace and materials.

-

NPE News in Extrusion

This NPE show won’t have a lot of extruders on the floor, either running or static. Instead, look for videos and announcements of new technology. You will also find lots of ingenious peripheral devices to improve output and quality and save resin. Some will do all three, and cost less into the bargain.

-

Plastic Pallets Gain Ground In an Eco-Conscious World

Low-cost wood is still king, but plastics’ reusability is a growing attraction among manufacturers looking for sustainable material-handling options. The one major hurdle is today’s high resin prices.

-

K 2007 Extrusion: Extrusion Outputs Go Through the Roof

Dramatic production demonstrations of cast and blown film set throughput records on the show floor in Dusseldorf.

-

Extruders Made in China: They're Coming Here Now

Low-priced Chinese-built extruders have arrived in North America to make pipe, sheet, film, and profiles. Some customers find them a good buy; others don’t. Here’s what you need to know.

-

What's New at the Show in EXTRUSION

It’s all about higher speeds and higher outputs at this year’s “K” show in Germany.

-

Small Molder Makes Big Parts

Some people might be tempted to lump all processors with annual sales under $10 million into the same category: shoot-and-ship makers of no-fuss products using straightforward processing.

-

NPE 2006 News Wrap-Up: Extrusion

NPE 2006 presented a bevy of features to make film, sheet, pipe, and profile extrusion more efficient.

-

What to See at NPE 2006: Extrusion

The new factor in extrusion machinery at this NPE is the influx of Asian suppliers.

-

What to See at NPE 2006: Injection Molding

Energy-saving all-electric machines will continue to be a big draw at NPE, where new designs or upgraded models will be found in virtually every press maker’s booth.

-

All-Electric Plant Gets World-Class Results

In mid-2004, Delphi Connection Systems, part of Tier 1 automotive supplier Delphi Corp.’s Packard Electric operations, flipped the switch on a new 190,000-sq-ft, $58-million plant in Vienna Township, Ohio.

-

Auto Glazing: Window of Opportunity for Molders

This emerging market promises to be big but challenging. Polycarbonate car windows require specialized machinery, high-end processing capability, premium polymers, advanced coating technologies, and innovative mold and runner designs.

-

Large Two-Platen Presses Gain Speed and Flexibility

An improved line of large two-platen injection presses offers new sizes plus greater speed, educed maintenance, more operator-friendly design, and added flexibility for a range of molding requirements.

-

Raising the Bar in Multi-Component Molding

Multi-component molding in North America makes up less than 10% of the injection molding business, but it is becoming a significant growth strategy for The Tech Group in Scottsdale, Ariz. "Rather than waiting for applications to come to us, which is what custom molders typically do, we are gathering the right technologies now to take our capability to a new level.

-

The Next Generation of Multi-Component Molding

Multi-shot and coinjection molding techniques are staking out new territory. Mach ines are getting larger and are combining more materials or colors in more sophisticated and imaginative ways.

-

K 2004 Wrap-Up on Injection Molding: Spotlight on Electric And Multi-Component Machines

Molders were treated to a trove of injection machinery introductions geared toward applications from micro-molding to packaging to large parts.

-

In-Mold Labeling Catching on in North America

Already a familiar sight on European store shelves, the eye-catching appeal of "IML" is gaining traction among North American injection molders. The latest tooling and automation designs can handle the higher volumes needed here.

-

K 2004 News Preview: Injection Molding

The diversity of electric machines will be on display at this year’s show, with several new all-electric versions in direct-drive and belt-driven versions.

-

In-Mold Lamination: U.S. Auto Market Is Catching Up

Although more widely used in Europe, in-mold laminating is gaining a foothold in U.S. automotive interiors. Molders can choose from a handful of different process technologies that promise labor and other cost savings.

-

Family Lumber Business Turns To Plastics

Five years ago, Quality Wood Treating in Prairie Du Chien, Wis., was a 30-year-old family lumber business and one of the largest wood pressure-treaters in the country.

-

NPE News Wrap-Up: Injection Molding

Stress-free production of large car windows, in-mold painting, and an injection unit that applies pack and hold while accumulating the next shot were a few of the cutting-edge technologies on display.

-

Injection Molding (K 2001 Preview)

All-electric machines will be one of the biggest themes in injection molding machinery at this year’s K show, where at least nine firms will bring out their first models.