Secure Customer Data Portal Billed a 'First' In Thermoforming

Brown Machine Group’s BMG Advanced Digital Readiness supplies customized process data to boost efficiency, reduce downtime.

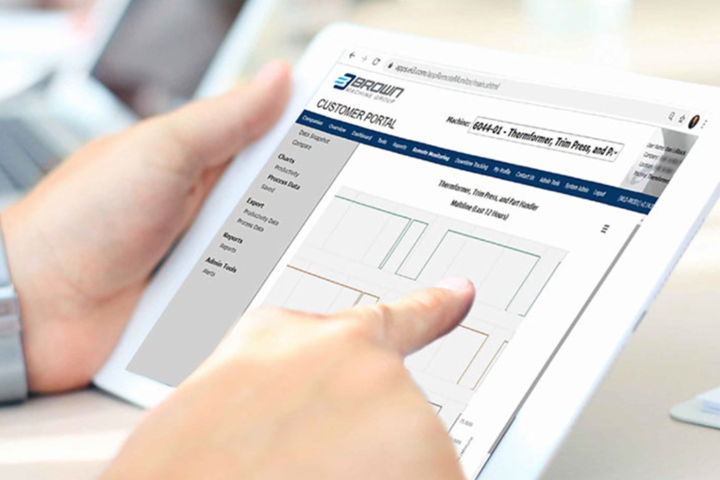

What is said to be the first secure customer data portal in the thermoforming market has been introduced by Brown Machine Group (BMG), Beaverton, Mich. A web- and app-based portal, the BMG Advanced Digital Readiness (BMG ADR) platform is designed for accessing important process data in thermoforming and product-handling applications. Available both with new installations and as a retrofit for most BMG machinery from the past several decades, ADR enables operators, maintenance personnel, operations teams, and executive leadership to interface with equipment securely and in real-time.

The new BMG ADR platform reportedly is highly customizable to meet individual customer requirements, with unlimited custom alerts by text message or email, for a wide range of possible alarm conditions. By customizing the ADR tool to their specific needs, users can review how critical assets are running, analyze unplanned downtime, and improve operations through notifications

The BMG ADR platform, available from anywhere via web browser or proprietary app, features enhanced security with automatic updates and allows customer-defined digital access to enable remote service sessions. Dedicated staff at BMG will be available to provide training and support, helping users make the most of the platform’s instantaneous feedback, customizability, and endless reporting functionality.

The platform, based upon ei3’s proven solution for manufacturing, is the first of its kind in BMG’s markets and heralds a new age of secure connectivity and IIoT-based information to ensure maximum uptime and efficiency. Based in New York City, ei3 Corp. delivers a suite of robust IoT and AI applications designed for manufacturing companies to increase machine performance, reduce downtime, improve quality, and reduce energy consumption.

Said John Block, BMG’s v.p. of purchasing & customer service, “This year’s pandemic has emphasized just how important building smart equipment and enhancing our remote service offering is. Although we were headed down the path to smart equipment prior to the pandemic, it accelerated our plans as customers need this technology; those who truly embrace and champion it will be more successful. Exploiting every opportunity for advantage is key in today’s uncertain environment and we’ve got a product that can assist in multiple ways, starting the payback cycle immediately.”

Related Content

-

Sustainable Materials is Focus of Thermoforming Exhibits at K 2022

Thermoforming equipment makers including WM, Kiefel, and OMV will showcase processing of recyclable and biobased materials.

-

An Automation 'First' for Non-Servo-Eject Trim Presses

Compact, flexible and configurable robotic system is said to be the first to enable thermoformers to fully automate product handling after a non-servo trim press.

-

OMV Technologies Gets New CEO

Kooper brings 33 years of experience in the industrial and consumer packaging industries to OMV--the closed-loop, turnkey, inline extrusion, thermoforming and tooling systems manufacturer.

(2).jpg;maxWidth=300;quality=90)