Testing

Colloidal Silica Processing Aid Slashes Molding Cycle Times

Ultra-fine synthetic silica particles have been shown in laboratory and commercial field trials to reduce injection molding cycle times by 20% to 30% in polypropylene, filled and unfilled nylon, PBT, and ABS.

Read MoreIndustrial CT Scanning Speeds Mold Qualification

Qualifying a mold often can take weeks and involve several costly and time-consuming steps.

Read MoreWeather Testing For the Real World

Broader use of plastics in building products and a growing desire to minimize painting of automotive parts is increasing the need for reliable predictions of light stability and weathering performance.

Read MoreEnhanced Color Matching Data Management

A new digital color formulation program combines powerful matching software with an easy-to-use interface that reportedly makes sharing color information faster and more secure than previously possible.

Read MoreRecyclers Now Targeting Higher-Value Engineered Resins

Recycling news from the Society of Plastics Engineers’ Global Plastics Environmental Conference (GPEC) in Orlando, Fla., in March focused on PET, nylon, and waste plastics in electronics—in other words, mainly on higher value engineered resins rather than commodities.Carpet recycling claimed two of the show’s big environmental awards.

Read MoreTaste and Odor: Understand the Role of Colorants and Additives In Food and Beverage Packaging

Do you know how masterbatch ingredients, processing, storage, and handling can affect taste and odor in packaged products? Here’s an introduction to the numerous factors in organoleptic properties and how they are measured.

Read MoreNon-Contact IR Analysis Simplifies On-Line Quality Control

A new method of mid-infrared analysis allows on-line monitoring of both the composition and physical properties of a plastic while it is being compounded or extruded.

Read MoreUltrasonic Imaging Finds Voids, Cracks and Bonding Defects

As material costs climb, acoustic micro-imaging (AMI) is increasingly being used for non-destructive inspection and quality control of microelectronic components and assemblies, adhesive and welded bonds, solid part walls, and other applications where bond integrity, cracking, or voids are an issue.

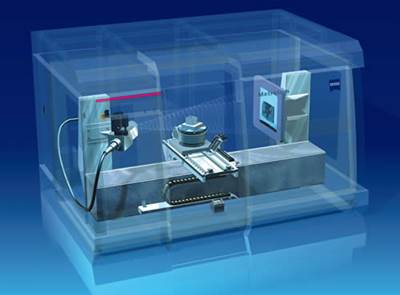

Read MoreNPE 2006 News Wrap-Up: Testing and QC--New Lab Instruments Stress Affordability and Convenience

Thermal and mechanical testers, color and appearance sensors, vision inspection devices and CMMs—the NPE had them all in more compact, economical, and easy-to-use models.

Read MoreA Custom Molder Takes the Next Step

The question John Winzeler keeps asking is, “How do you take the next step?” In the last two decades, he has transformed the Chicago metal-stamping company he inherited from his father into a high-tech specialty molding business focused only on plastic gears.

Read More

(2).jpg;maxWidth=300;quality=90)