Mold Simulation

Latest Mold Simulation Articles

VIEW ALLHow to Achieve Simulation Success, Part 1: Model Accuracy and Mesh Decisions

Molding simulation software is a powerful tool, but what you get out of it depends very much on your initial inputs. Follow these tips to create the most successful simulation possible.

Read More50 Years...600 Issues...and Still Counting

Matt Naitove marks his first half-century in plastics reporting, with a few of his favorite headlines.

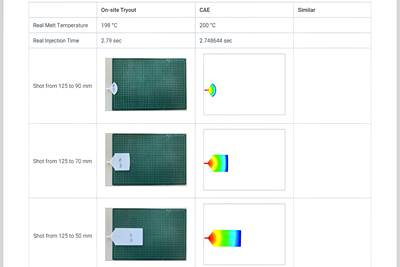

Read MoreInjection Molding Simulation Meets the Real World

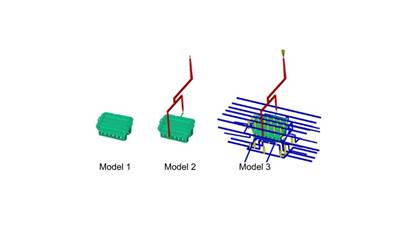

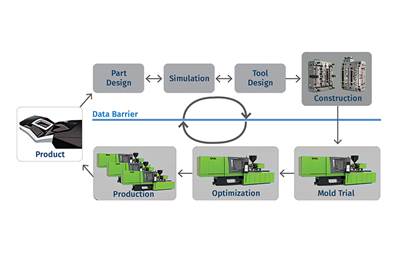

Direct data interface between molding simulation and the injection machine links the computer model to the real-world process. This can improve results from product and mold design through ongoing production. A case study demonstrates these benefits for automotive components in a family mold.

Read MoreTake Time to Save Time: Five Steps in Mold Design to Reduce Back-End Troubleshooting

Westminster Tool shares how the one week it typically takes to perform these five steps in the design phase can save three weeks or more in an overall tool build.

Read More50 Years of Headlines … Almost

I was lucky to get an early look at many of the past half-century’s exciting developments in plastics. Here’s a selection.

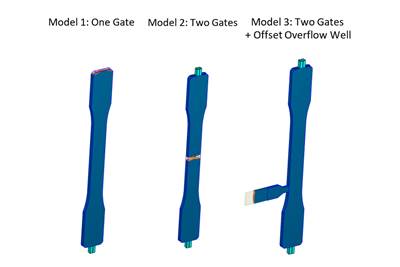

Read MoreTry Overflow Wells to Remedy Weld Line Weakness

Molding simulations show that adding an overflow well to a part can mitigate the impact of glass fibers on weld-line weakness.

Read MoreLatest Mold Simulation News And Updates

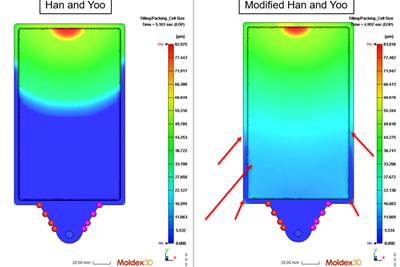

Foam Molding Simulation Gains Better Bubble-Shrinkage Prediction

Microcellular foam molding simulation improves prediction of cell size and distribution in thin sections, core-back processes.

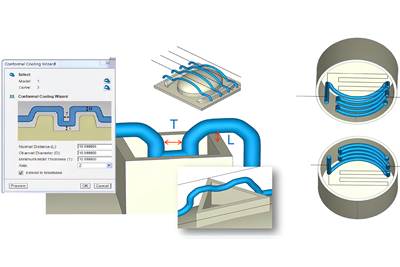

Read MoreUpgraded Simulation Package Adds Nozzle Zone & Conformal Cooling ‘Wizards’

Wizards assist conformal-cooling layout and simulation of melt compression in the nozzle in Moldex3D 2021.

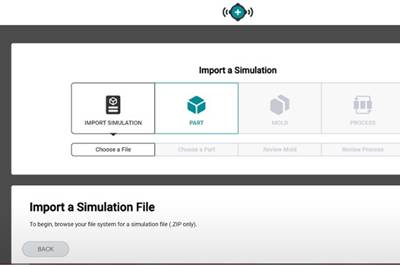

Read MoreInjection Molding Networking Software Adds Simulation Support

RJG’s Hub now supports Moldex 3D and Autodesk’s Moldflow/Insight injection molding simulation software.

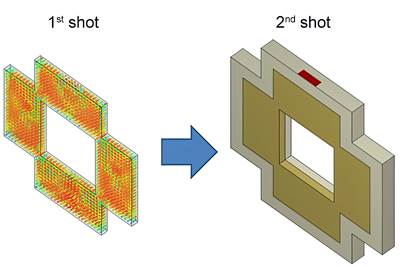

Read MoreSimulating Two-Shot Molding: How Does the First Shot Affect Overall Part Warpage?

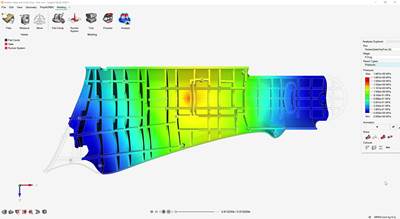

Moldex3D simulation can integrate analysis of the first-shot temperature, pressure, and fiber orientation into warpage analysis of the second shot.

Read MoreInjection Molding: Store, Manage & Analyze Mold Simulation Data in the Cloud

Moldex3D iSLM helps manage, share and easily analyze large volumes of mold simulation data.

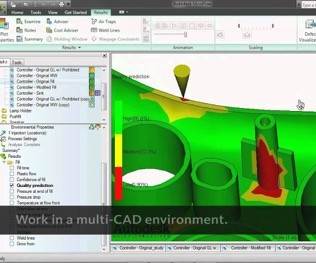

Read MoreInjection Molding Simulation Platform Launches

Altair says its Inspire Mold program provides a simulation-driven approach for injection molding design for manufacturing (DFM).

Read MoreFeatured Posts

Why Put Flow Simulation on an Injection Machine?

This emerging technology sounds promising, but its practical benefits have yet to be demonstrated clearly.

Read MoreScared Straight on Molding Simulation

Molding simulation is such a vital technology today that many molders couldn’t imagine life without it. But as a “consumer” of such a service, you have to know how to carefully critique the simulation results, which can hide a multitude of shortcuts and compromises that threaten their utility.

Read MoreGoing for the Green vs. Getting in the Hole

Too often when designing a tool or establishing a process, molders go for the hole in one when they only need to aim for the green.

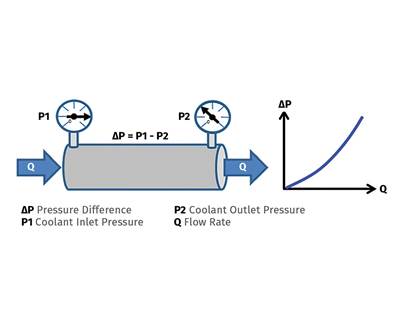

Read MoreIs Your TCU Up to the Job? Mold Simulation Can Give the Answer

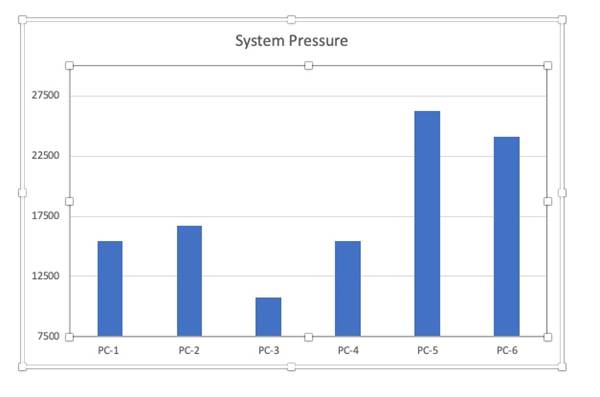

For realistic results, molding and cooling simulation must reflect the capabilities of the actual TCU to be used. Here’s how simulation can help determine whether your TCU is up to the job.

Read MoreSee the Mold Filling on Your Press Control Panel

Arburg embeds flow simulation in its Gestica controller.

Read MoreNew Webinar: How to Use Simulation to Reduce Material and Part Cost

Register for this free webinar on reducing downstream risk through injection molding simulation software. (Sponsored Content)

Read More

.png;maxWidth=300;quality=90)