Blow Molders Save Big On Compressed Air

Molders of PET containers are paying special attention these days to the large amounts of compressed air used in their blow molding operations and the huge energy cost associated with generating it.

Molders of PET containers are paying special attention these days to the large amounts of compressed air used in their blow molding operations and the huge energy cost associated with generating it. With the skyrocketing cost of energy, particularly in New England and California, many PET bottle makers have started to view compressed air as the “fourth utility,” along with gas, water, and electricity, according to Chris Gordon, president of Blackhawk Equipment, Arvada, Colo., an air-systems specialist who handles the compressed-air needs of bottle producer Ball Corp., Broomfield, Colo.

“PET molding requires ultra-high air pressures, in excess of 580 psi,” explains Gordon. Compressors typically have the largest motors in a blow molding plant, consuming millions of dollars worth of electricity each year. So large manufacturers like Ball and Southeastern Container Inc., Enka, N.C., are seeking the best approach to reduce compressed-air usage, reduce energy costs, and sometimes even earn lucrative utility rebates on electric power usage.

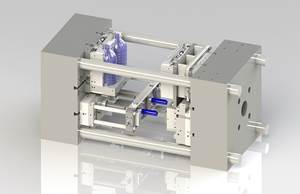

Gordon is a big believer in an innovative air-recovery system that recycles compressed air and significantly cuts energy costs. The Air Recovery System (ARS) from Technoplan Engineering SA of Geneva, Switzerland, recovers compressed air after bottle blowing, which still has enough residual pressure to be useful for many tasks. The U.S. distributor of the ARS system is Connell Industries Inc., Rahway, N.J., a control-systems engineering company.

The ARS system is installed between a blow molding machine’s exhaust system and the plant’s low-pressure air system. It captures and stores almost 50% of the dry, oil-free post-blow air at a pressure of 12 bar (170 psi). Reclaimed air is returned to the plant’s low-pressure air system to be used anywhere in the facility.

Quick payback

Ball installed the ARS system at its Baldwinsville, N.Y., bottle plant and netted a large energy savings, Gordon reports, though exact figures are unavailable. A large compressor was shut down, saving thousands of kilowatt-hours of energy, and maintenance costs were also reduced. Total savings generated from an ARS system typically results in payback within 8 to 12 months, according to Gordon.

In New England, where electric utility rates are among the highest, positive results have also been registered at Southeastern Container in Hudson, N.H., where 1.5 million PET bottles are produced each shift for Coca-Cola Co., its parent company. Southeastern installed two ARS systems on Sidel SBO 40 stretch-blow machines that produce 2L and 20-oz PET bottles. The ARS recaptures about 800 CFM of low-pressure air, according to John Fischer, Southeastern Container’s Northeast general manager. “That allows our compressors to rest,” he notes.

The results are impressive: The Hudson plant saves at least 5 million kwh per year and $300,000 in the first half of 2007 alone. That means the payback will be less than one year, even without the rebate from the local utility, Public Service of N.H., for about half the cost of the ARS systems. As a result, Southeastern Container is considering adding more ARS systems for 2L bottle production at other plants.

The ARS system costs approximately $4500 plus installation charges. About 350 systems have been installed worldwide at PET blow molding plants.

Related Content

Stretching the Boundaries of Large PET Containers

NPE2024: Cypet shows off new capabilities for its ISBM machines.

Read MoreServices to Help Blow Molders Convert to rPET

Sidel launches “RePETable” range of services as “one-stop” solution to efficient adoption of rPET for bottle production.

Read MoreAt NPE, Cypet to Show Latest Achievements in Large PET Containers

Maker of one-stage ISBM machines will show off new sizes and styles of handled and stackable PET containers, including novel interlocking products.

Read More50 Years...600 Issues...and Still Counting

Matt Naitove marks his first half-century in plastics reporting, with a few of his favorite headlines.

Read MoreRead Next

Why (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read More

.png;maxWidth=300;quality=90)