How to Optimize Your Molds and Hot Runners for Processing Bioresins

Demand for bioresins is growing in molded goods, particularly as a sustainability play to replace fossil-fuel based materials, but these materials are not a drop-in replacement for traditional materials. Molds and hot runners need to be optimized for these materials.

Across multiple industries and applications, bioresins have become increasingly popular alternatives to the traditional resins used in injection molding. The global market for bioresins has risen steadily over the years and is expected to continue that growth at an impressive rate. Over the next five years, the market is expected to double in size, with a compound annual growth rate (CAGR) of 17% in the U.S. and 13% in Europe.

What’s driving the growth in bioresin adoption? First are consumers who want to know that the product they purchased, as well as its packaging, is sustainable. Because bioresins are derived from relatively sustainable materials and can be engineered to biodegrade, many consumers feel bioresins are a more sustainable choice.

The second driver is environmental, social and governance (ESG) initiatives. Brands and molders are under increasing pressure to adopt an ESG strategy. Using bioresins for injection molded products and packaging can help organizations meet their ESG objectives and signal to consumers that they’re doing their part for the environment.

The final driver is legislation. New legislation and regulations are placing pressure on manufacturers to reduce postconsumer waste and plastic pollution. In July 2021, for example, the European Commission implemented new laws that ban or restrict single-use products made from fossil-fuel-based polymers.

Danimer’s Nodax PHA created through a fermentation process, utilizing canola oil as feedstock. Photo Credit: Danimer

Putting the “Bio” in Bioresins

Bioresins — sometimes called bioplastics, biopolymers or biomaterials — refer to several categories of commercially available materials that can be used in injection molding and other processes. So, what makes these plastics “bio”? The materials are made in whole or in part from renewable biological resources. These biological resources can include corn or maize, potato starch, tapioca starch, vegetable oil, sugar cane starch and wood pulp or cellulose among other feedstocks.

When planning to use bioresins, it’s important to note a few distinctions in related terminology and features. Biobased refers to the fact that biomaterials are used to create the resin. Biodegradable means the item will eventually breakdown in the natural environment. Not all biobased resins are biodegradable. Compostable means the material is biodegradable and breaks down within three to six months in an industrial composting facility, releasing nutrients and leaving no toxicity in the soil. Not all biobased and biodegradable materials are compostable.

What Traditional Materials Can Bioresins Replace?

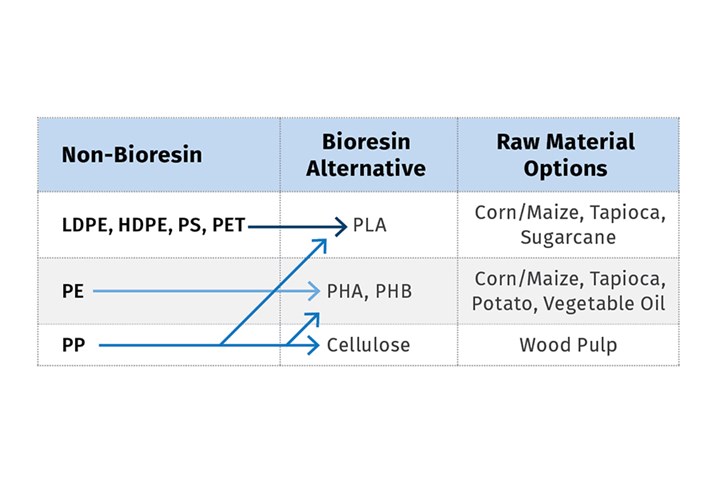

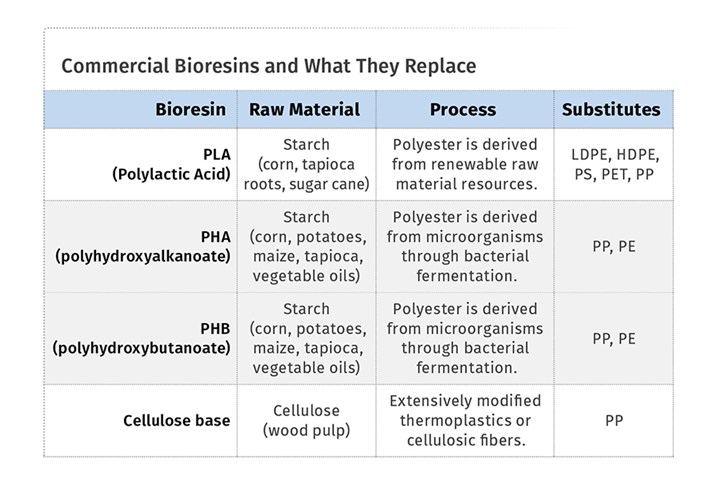

In most applications, high- and low-density polyethylene (HDPE, LDPE), polystyrene (PS) and PET can be replaced by polylactic acid (PLA). PLA is one of the first bioresins to be commercialized, and its feedstock options include corn or maize, tapioca and sugar cane.

Bioresins serve as a viable replacement for various traditional polymers.

PE can be replaced with polyhydroxybutyrate (PHB) or polyhydroxyalkanoates (PHA), which are relatively newer resins on the market. These bioresins have more processing options and can offer compostability. PHA and PHB can be produced from corn; tapioca or potato starch; and vegetable oil. Many of the polypropylene (PP) parts molded today can be replaced with a cellulose resin made from wood pulp.

Bioresin Challenges and Best Practices

Bioresins come with unique and challenging physical properties that can make them difficult to incorporate into the injection molding process. For example, many bioresins are highly viscous and require high pressures to fill the mold cavities. They’re also prone to weepage and leakage. In terms of manufacturability, some bioresins are very temperature sensitive, so the manufacturing process must avoid exceeding temperatures above a certain threshold.

One of the most frequent mistakes we see is people thinking because bioresins replace PP and PE, they process similarly to those resins. Bioresins are more thermally sensitive, and their process window is smaller, so running them requires equipment that’s designed to deal with those constraints.

Any new materials also bring unknowns, especially in performance, and many bioresins may not perform as well as traditional materials in terms of product preservation, longevity, safety and other key metrics. These unknowns need to be addressed to achieve a successful bioresin adoption. Bioresins are not a straight replacement for PP and PE. Even within petrochemical based PE and PP, there is a wide variation in performance among the numerous grades. Make sure that the bioresin you’re choosing matches the requirements of the product that you’re bringing to market.

Not all biobased resins are biodegradable; and not all biobased and biodegradable materials are compostable.

Equipment impact is another area where bioresins may not initially meet the same standards as traditional materials. Molten bioresins tend to be corrosive, especially in the case of PLA, which can compromise machinery and lead to quality issues, performance variation and even component failure.

This may require more frequent equipment inspection and maintenance to ensure consistent and predictable uptime. PLA can cause damage to not just the hot runner and the mold but the screw and barrel as well. Basically, anything that touches the melt needs to be stainless steel or have a nonreactive coating.

Weepage and leakage are also an issue. This is partly due to the material’s corrosive nature, but also its molecular structure tends to weep or leak. In the case of a valve-gate system where there are moving parts, weepage is possible. When there are moving parts like valves, stems and bushings, their design needs to take into consideration the possibility of weepage.

Weepage and leakage can pose issues if bioresin molding applications.

Bioresin preparation includes drying to a moisture content of less than 250 parts per million (ppm) to prevent viscosity impacts and resin degradation. Bioresins are usually supplied in foil-lined bags or bags that are dried to less than 400 ppm in moisture. These resins should not be exposed to atmospheric conditions after drying.

In processing, the pre-sealed bag is ideally opened and loaded directly into the dryer. The bag should not be left open for an excessive amount of time, and users shouldn’t drain the resin from the dryer after it has been dried and leave it out. Errors in drying and handling can have a particular impact on mechanical performance.

Remember: The corrosiveness of some bioresins goes up almost exponentially as they degrade.

If a color change will be required, the channels must be sized so the shear rates are on the high side, which results in proper scrubbing of the melt channels, expediting color switchovers. With these inputs and using the output from several software packages, the optimum geometry for the melt channel, including its layout and channel diameter, can be determined.

Application Review

Conduct an in-depth review of the application and the bioresin itself prior to any manufacturing. This review ensures the hot runner and controller are optimized for the specific application and bioresin. This should include optimizing the manifold design for consistent preparation of the bioresin.

To optimize the application, an in-depth review of the component and the bioresin should be conducted, including a cavity-fill analysis of the part design to verify all features are compatible with the rheology of the chosen bioresin. The bioresin supplier should be able to characterize flow characteristics, and ideally, the simulation will model the actual resin and not a substitute material. The need for a resin trial can also be evaluated — a step that is usually recommended for resins with limited performance data or in particularly challenging applications.

Bioresins are derived from a number of sources.

Husky is currently working with many of the bioresin suppliers to test and validate their materials, including new formulations as they go to market. In its lab, Husky has around 45 different molds with different part configurations to test an assortment of resins and help customers determine if a particular bioresin is right for a specific application. Compostability testing with the bioresin you’ve chosen is possible and required for commercializing a product with a compostability certification.

Derived from a variety of sustainable feedstocks, bioresins can be processed in various ways to meet the needs of many applications. Photo Credit: Husky

Pinpointing Pressure

The pressure requirements for processing the bioresin need to be evaluated because viscosities for these materials can be very different from standard polyolefins. Determine if the machine and hot runner being used can generate adequate pressure to process the material. In general, Husky recommends machines that can achieve pressures of at least 28,000 to 32,000 psi.

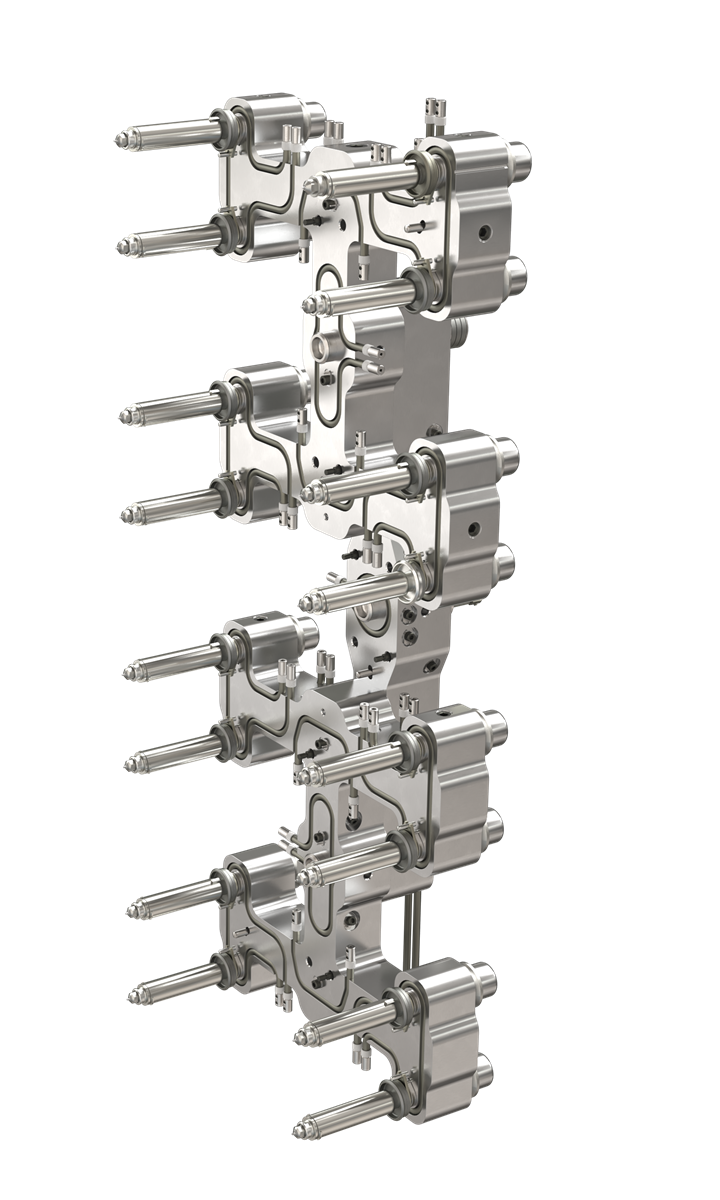

In addition, the resin melt temperatures are relatively low and there is a comparatively low Delta T or difference between the melt and mold temperature. The next step is optimizing the hot runner and the controller for the bioresin, including using corrosive-resistant components and high-level melt management.

Individual tip control is highly recommended for bioresins, as it would be for all temperature-sensitive resins. Improved heat distribution is required to control any overshoot, and the controller should be designed specifically for low-variation, high-temperature control to eliminate overshoots, if possible.

In addition, it is best for the hot runner controller to be tied into the injection molding machine’s control. This is recommended because if the machine goes down for a predetermined amount of time without an operator, when the molder restarts the press, it’s best to have the controller automatically put the heat in standby on the hot runner to prevent material degradation during the idle.

The corrosive properties of bioresins, particularly as they degrade, require melt-contact surfaces to use specialized coatings or be in stainless steel.

Also, remember that the corrosiveness of the resin goes up almost exponentially as it degrades, making the ability to flush any degraded resin out important. Degraded bioresins will attack the steel components in the hot runner and can also damage the mold if injected.

Ensuring the manifold design is optimized for bioresin includes applying geometrically balanced channels so the melt traveling from the sprue bushing to every cavity, whether there are two or 96, experiences the same, if not similar, rheology profiles.

Remembering that the melt channel size and distance covered helps determine the shear rates, molders should consider and optimize these for low pressure, reduced shear and minimal residence time, bearing in mind that the smaller the channel, the higher the shear rate and the lower the residence time. The counterpoint to that setting profile is pressure drop. Molders need to ensure that for some specific bioresins, the channel is not too small and there isn’t too much pressure drop, which could prevent the parts from filling. Each manifold should be engineered specifically to the application and then balanced between pressure drop, shear rate and residence time requirements.

Stainless steel hot runner systems, like this UltraMelt system designed by Husky Technologies, can resist the corrosive nature of some degraded bioresins. Photo Credit: Husky

The performance characteristics to be expected, including in areas such as pressure drop; shear rate in the hot runner; shear rate at the gate; and the temperature increase as a result of that shear rate can be derived. For thermal uniformity, a Finite Element Analysis (FEA) is a good predictor of manifold temperature variation due to the design of the hot runner. By adjusting the design — including the number of heater zones, thermocouple placement, melt channel layout sinks and manifold profile — the designer can optimize the thermal uniformity of the manifold prior to manufacturing.

About the author: Sheldon Alexander is hot runners business manager for Husky. He has more than 20 years of global industry experience, traveling the world to help optimize injection molding applications for customers in more than 40 countries. Alexander has experience managing highly skilled teams across many functions in the injection molding value chain and holds several technical patents in the industry with specific expertise in hot runners. Contact: 905-951-5000; salexand@husky.co; www.husky.co

Related Content

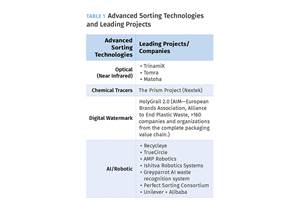

Recycling: What's Ahead in Advanced Sorting Technology

As the industry tries to ramp up recycling, there are several innovative sorting solutions in the offing—ranging from enhanced optical sorting technologies and chemical tracers to advanced solutions based digital watermarks and artificial intelligence.

Read MoreFoam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

Read MoreAvoid Four Common Traps In Granulation

Today, more than ever, granulation is an important step in the total production process. Our expert explains a few of the many common traps to avoid when thinking about granulators

Read MoreHow to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

Read MoreRead Next

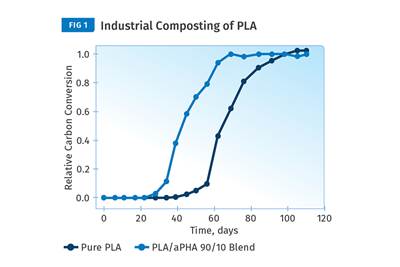

How to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

Read MoreHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

Read MoreBlend Amorphous PHA with PLA to Improve injection Molded Part Properties

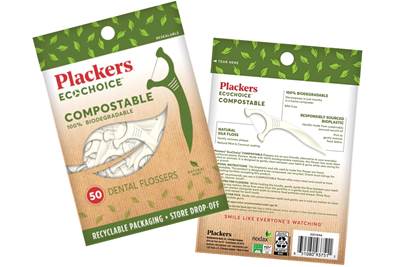

Adding aPHA to PLA can boost a range of mechanical properties and expedite composting. Here are the details as well as processing guidelines for injection molding the blends.

Read More