Blend Amorphous PHA with PLA to Improve injection Molded Part Properties

Adding aPHA to PLA can boost a range of mechanical properties and expedite composting. Here are the details as well as processing guidelines for injection molding the blends.

Share

Read Next

Injection molded prototypes made with PLA/aPHA blends include cases for cosmetics. (Images: CJ Biomaterials)

Biopolymers such as polyhydroxyalkanoate (PHA) and polylactic acid (PLA) are versatile, compostable and biocompatible materials derived from natural resources such as corn, sugar beets and potato starch, and are excellent candidates for producing commercially compostable packaging materials. PLA adoption has grown significantly in recent years, but some drawbacks — including low elongation at break and brittleness in comparison with traditional petroleum-based polymers — have limited the range of applications in which it is employed.

In this article we explore the use of amorphous polyhydroxyalkanoate (aPHA), which is commercially produced by CJ Biomaterials (a division of CJ CheilJedang), to improve the mechanical properties of brittle polymers such as PLA in injection molding applications. While modification of PLA is the focus here, a similar approach may be employed for a variety of other polymers used in molding applications.

What’s aPHA?

aPHA is a type of biopolymer that belongs to the family of PHAs, which are biodegradable aliphatic polyesters produced by various microorganisms as a means of energy storage. Unlike other types of PHAs, aPHA is a non-crystalline or amorphous polymer, meaning that it lacks the highly ordered structure found in semi-crystalline polymers. In 2022, CJ Biomaterials commercialized Phact 1000P aPHA, which has several unique properties that make it a promising material for various applications.

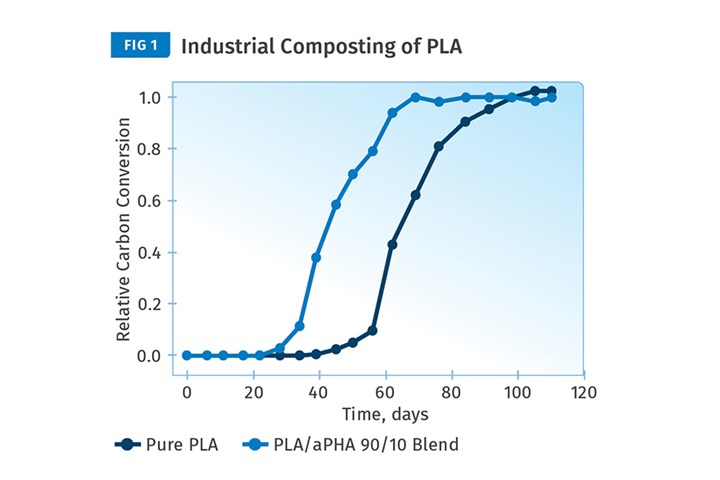

Adding 10% aPHA to PLA yields 25-30 days faster composting. (Photo: CJ Biomaterials)

For example, its low glass-transition temperature (Tg) around -17℃ leads to high stability and elasticity at low temperatures, compared with semi-crystalline PHAs in the market. The high biodegradability of aPHA is also one of its most remarkable characteristics. It is certified to be biodegradable in various environments, including soil and marine, by microorganisms that can use it as a carbon source.

The value of aPHA is to work with PLA or other biopolymers that are brittle and rigid.

As a result, it can be regarded as an attractive alternative to petroleum-based plastics. (It should be noted that the value of aPHA is to work with PLA or other biopolymers that are brittle and rigid, where it can help improve their performance and quicken their rate of composting compared with PLA alone.)

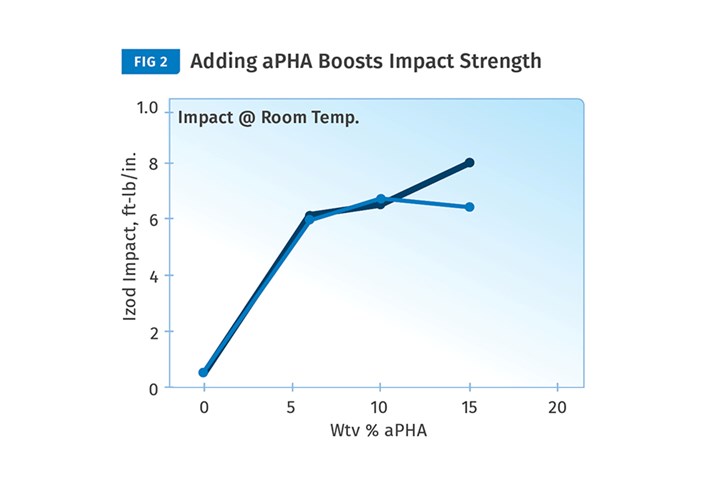

Addition of aPHA to PLA improves impact strength and ductility at room temperature. (The two different curves represent two different lots of aPHA.)

Photo Credit: CJ Biomaterials

Addition of aPHA to PLA results in the following advantages relative to pure PLA:

• Faster PLA industrial composting. As shown in Fig. 1, blending 10% aPHA with PLA permits composting times about 30 days faster.

• Considerable impact toughening of PLA. As shown in Fig. 2, aPHA can enable PLA to transition from a brittle polymer to a ductile polymer.

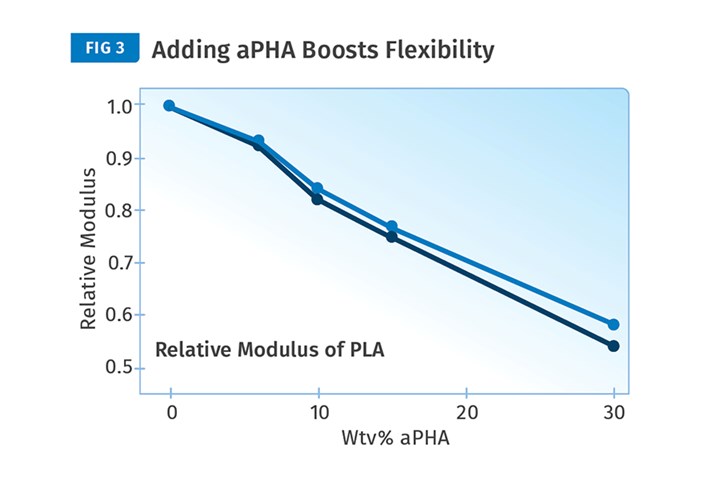

• Improved flexibility and potential for living hinges in molded parts. Figure 3 shows the influence of aPHA addition on the modulus of PLA.

Based on those performance features highlighted, it’s clear that blends of PLA and aPHA are useful biobased (100% bio-carbon) and compostable alternates to plastics such as ABS, PP, PS, HIPS and PET in many molding applications. These blends are also certified for food contact by the U.S. FDA.

Adding aPHA to PLA improves flexibility and potential for living hinges. (The two different curves represent two different lots of aPHA.) CA1180P,

Photo Credit: CJ BiomaterialsKey Processing Considerations

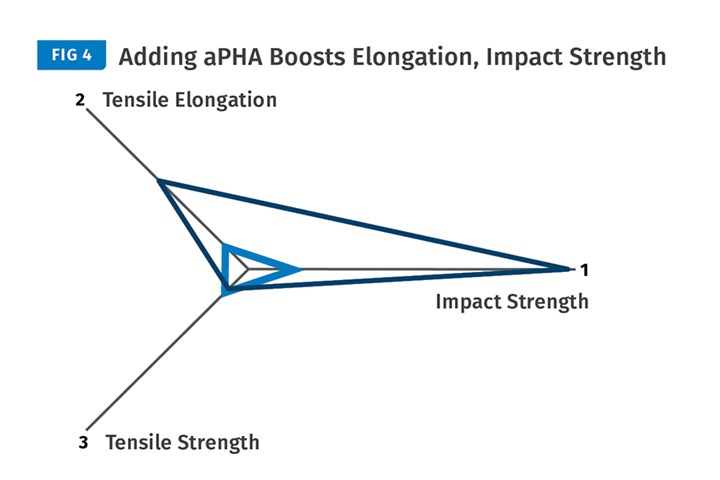

To date, CJ Biomaterials has introduced two compounds for injection molding, CA1180P and CA1170P, which are based on PLA and aPHA along with a small amount of mineral filler. Their cost and performance are differentiated by the content of aPHA and mineral filler. The spider chart (Fig. 4) demonstrates the performance of CA1180P relative to a standard PLA injection molding grade. It is evident that CA1180P, which is 100% biobased and compostable, has significantly higher impact strength and elongation relative to PLA alone, while only a modest decrease in strength is evident.

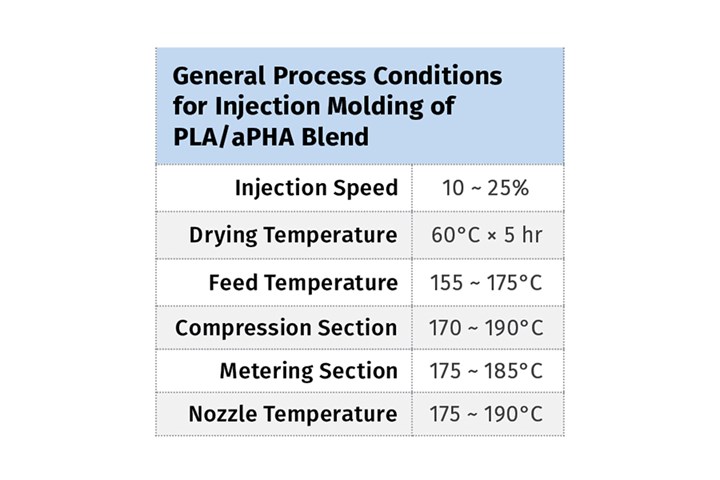

CA1180P can be processed on conventional electric and hydraulic reciprocating-screw injection molding machines. General process conditions are similar to those of PLA. Hydrolysis, thermal stability and warpage/shrinkage are among the factors that must be accounted for in molding both PLA and compounds of PLA with aPHA. Because aliphatic polyesters are susceptible to hydrolysis at typical processing temperature, the products must be dried prior to molding.

CA1180P, a blend of PLA and aPHA, has higher elongation and impact strength than pure PLA.

Photo Credit: CJ Biomaterials

These polymers are also prone to chain scission at higher than nominal processing temperatures that can arise from excessive shear. These attributes call for processing temperatures below ~200°C. The injection speed and screw rpm must be moderate. High-shear regions such as flow through the gate must be appropriately addressed through gate design.

Because aliphatic polyesters are susceptible to hydrolysis at typical processing temperature, the products must be dried prior to molding.

Other useful processing guidelines are as follows:

▪ Warping and shrinkage: PLA/aPHA blends have a relatively high coefficient of thermal expansion, which can cause warping and shrinkage of the parts during the cooling phase of injection molding. To minimize this, it is critical to use proper cooling methods, such as uniform cooling across the mold surface and adequate cooling time. And a slower than normal injection speed and additional holding pressure can help fill the part without much shrinkage and flash.

▪ Mold temperature: This directly affects the cycle times. At a mold temperature of 30℃, the cycle time for CA1180P PLA/aPHA blend is 20–35 sec. On the other hand, more than 100 sec of cycle time is required for high-temperature molding (110℃) typically used for crystallizing the PLA in-mold.

▪ Holding pressures and time: The second-stage injection pressure (i.e., holding pressure) should be just enough to fill the last 1% to 5% of the part and maintain a full part as it cools and shrinks in the cavity. For PLA/aPHA blends, holding pressure is typically 15% to 30% of the first-stage peak injection pressure and should start low and increase gradually until the part fills but does not flash.

The optimal hold time is the time that it takes the gate to seal off, at which point the weight of the part does not increase with further holding. For PLA/aPHA blends, hold times of 3–10 sec are common; longer hold times can be used for more complex parts. Sink marks and voids in the part indicate insufficient hold time.

▪ Cooling time: This should be long enough that the part ejectors do not penetrate the part. The part should not stick in the cavity and eject freely. The cooling requirements of a part are strongly dependent on its wall thickness. It is recommended to start long — e.g., 15–30 sec — to ensure the part can be ejected, and then gradually reduce the cooling time when the cycle is running. At a minimum, the cooling time will be equal to the screw recovery time.

To develop the ultimate physical and appearance properties of PLA/aPHA blends, the material should be processed at the maximum allowable melt temperature without excessive thermal degradation. It should be injected at slow speed, packed at the minimum pressure required to fill out the mold details, and packed long enough until the gate freezes.

ABOUT THE AUTHORS: Max Senechal is the chief commercial officer at CJ Biomaterials. He has more than 25 years’ experience in the chemical and material industries, with the last 13 years spent on the development of biomaterials at Metabolix, Ginkgo Bioworks, and CJ Biomaterials. Contact: (339) 999-2693; max.senechal@cj.net; cjbio.net.

Raj Krishnaswamy is v.p. of polymers R&D at CJ Biomaterials. He had over 20 years of polymers R&D experience at Chevron Phillips Chemical, Metabolix and Braskem prior to his current stint at CJ. Raj is a co-inventor on 50+ patents and a co-author on 40+ publications. He is a Fellow of the Society of Plastics Engineering (SPE), has been recognized with the Research/Technology lifetime achievement award by the SPE, and is an alumnus of the NAE Frontiers of Engineering. Contact: (339) 999-2693; raj@krish.cj.net; cjbio.net.

Eunhye (Grace) Lee is the group manager of polymer application R&D at CJ Biomaterials. She has a Ph.D in polymer engineering from Osaka University and over 10 years’ experience in research on biopolymers. In particular, she has led application studies on biopolymers such as PLA, PHA, and PGA. She recently published several papers on the behavior of polymer properties and the use of biopolymers. Eunhye is currently conducting research on improving the physical properties of PHA biopolymers and compounds including tuning rates of biodegradability. Contact: (339) 999-2693; grace.lee@cj.net; cjbio.net.

Related Content

Melt Flow Rate Testing–Part 1

Though often criticized, MFR is a very good gauge of the relative average molecular weight of the polymer. Since molecular weight (MW) is the driving force behind performance in polymers, it turns out to be a very useful number.

Read More50 Years...600 Issues...and Still Counting

Matt Naitove marks his first half-century in plastics reporting, with a few of his favorite headlines.

Read MoreCJ Bio’s Amorphous PHA Demonstrates Excellent Biodegradability in Marine environment

The tests of the bioplastic, a semi-crystalline PHA and a PLA were conducted by the national Korean testing agency (KCL)

Read MoreCling Wrap Made from Potato Waste

Australia’s Great Wrap to expand into U.S. with home compostable cling wrap and its refillable dispenser made from recycled PET bottles.

Read MoreRead Next

CJ BIO and NatureWorks Working Towards a Master Collaboration Agreement to Commercialize Novel Biopolymers

The two companies have agreed to collaborate on creating advanced products based on industry-leading Ingeo PLA and Phact PHA technologies to meet growing demand for sustainable materials across a broad array of markets

Read MoreCJ Biomaterials Launched First Consumer Brand Cosmetic Packaging Application

Olive Young’s Wakemake cushion container made of PHA and PLA

Read MoreAmorphous PHA Gets Green Light from FDA for Food-Contact Applications

FDA listing clears the way for CJ Biomaterials’ amorphous polyhydroxyalkanoate to be used in the manufacture of food contact materials sold in the U.S.

Read More