Liquid Injection Molding Hits Its Stride

Liquid silicone rubber (LSR) has come a long way over the past two decades. From its roots in a few specialty applications where premium physical properties counted more than the premium price, this thermoset carved out a small but solid niche in the medical and automotive fields. Now, among a proliferation of new applications, that niche has begun to burst at the seams.

Dow Corning and GE Silicones, the two largest LSR suppliers in North America, both report that they are experiencing sales growth in excess of 10% per year. "We see double-digit growth for this market, and the pace is accelerating," says Dan Gordillo, LSR product manager at GE Silicones. Suppliers of liquid injection molding (LIM) machinery paint a similarly rosy picture. Engel Canada has seen double-digit growth in sales of LIM systems over the past four years, according to John Timmerman, sales manager for elastomer machines. Engel isn't alone: "We sold more LIM machines last year than ever before," says Wolfgang Meyer, president of Battenfeld of America.

Behind LSR's sudden popularity are advances in processing and materials technology that have made these pricey materials more competitive with latex or high-consistency silicone rubber (HCR) that cost half as much. With basic LSR grades starting at more than $5/lb, and specialty grades spiraling up from there, LSR desperately needed a boost from technologies that could improve productivity and drive down part cost. According to Dow Corning marketing manager Bill Logan, modern LIM equipment and new LSR materials permit higher cavitation, faster cycles, and lower scrap rates. "The machines, tooling, and materials are finally starting to come together," Logan says.

Much of LSR's recent growth has come from what Logan calls "cannibalization" of applications for HCR and other elastomers. "LSR is a good choice in more and more applications because its clarity, chemical resistance, and other beneficial properties don't change over a huge range of temperatures," he says. Common applications include spatulas, eyewear, and sporting goods. As a replacement for latex, LSR is seeing increased use in baby-bottle nipples and pacifiers. It has also replaced nitrile rubber in parts as varied as oil-filter valves and diving masks.

Taken together, the new applications and technology advances promise to propel LSR even further into the molding mainstream

Thermoplastic molders should take note that LSR shows some promise as an alternative to TPE in applications where its physical properties offset its price premium. Timmerman believes these will be limited to cases where TPE's physical properties are marginal in relation to end-use requirements. "Molders specializing in TPE need to be aware of LSR," says Timmerman. "It has all the advantages of a TPE without many of the disadvantages of other thermosets."

Strangely enough, LSR has even replaced TPE in disposable products. Logan notes that Dow Corning's LSR was chosen over TPE in a line of fluid-dispensing valves from Liquid Molding Systems, Midland, Mich. These patented valve designs are used in consumer-goods packaging such as shampoo bottles. Newer versions have been applied to "bite valves" for sports beverages and children's cups.

Multi-material marriage

Dual-durometer combos

LSR goes farther with gas

Combining LSR with gas-assist molding is another emerging area of interest that should open new doors for LIM. At K'98, Engel showed a patented LSR gas-assist system that produced a hollow catheter on a 60-ton tiebarless machine. "This type of part would normally be extruded and finished with secondary operations," says Timmerman. The gas-molding cell used a two-cavity cold-runner mold from Austrian moldmaker RICO. Timmerman notes that gas assist with LSR is an extension of Engel's coinjection technology in that the system treats the gas like a second material component.

Boy Machines, which offers LIM configurations of all its machines from 14 to 88 tons, is also at work on pairing LIM with gas assist. Sales manager John Pirro reports that the company has developed a nozzle specifically for localized injection of gas into LSR parts. "Because of the material rheology, it's harder than in thermoplastics to get the gas where you want it," Pirro notes.

How large is large?

In the LSR world, a part weighing a few ounces is considered large. But GE Silicones' Gordillo reports that in Europe, this expensive material is starting to be used in big high-voltage electrical insulators that can contain up to 40 lb, and sometimes even more than 100 lb, of silicone. Traditionally, these parts have been porcelain. "But the trend now is a move away from ceramics," Gordillo says. Although most of the current market for such parts is in Europe, both GE Silicones and Dow Corning believe there will ultimately be a worldwide market for large LSR insulators. Both firms have introduced material grades for high-voltage applications. However, molding dozens of pounds of silicone at a shot will not be for everyone. Specialized machinery is needed, according to GE application engineer Greg Gensler.

Engel has developed a new LSR machine with a double-plunger injection unit to handle shot sizes from 2.4 to 48 lb. Unlike many LSR applications, which tend to require less clamp force than conventional injection molding, these presses are sized between 110 and 660 tons. "We believe this application needs about 2 tons/sq in. of projected area," says Timmerman. These large LIM machines come in vertical and horizontal configurations, including tiebarless versions. "Tiebarless models are a good fit because some of the electrical parts have fiberglass rods or aluminum castings that extend beyond the mold," notes Timmerman.

Timmerman says Engel has sold some machines for large electrical-insulator applications. They have been vertical models with three injection units (1000, 6000, and 10,000 cc) to accommodate the wide shot-size range needed for different types of insulators. "The injection units can be run individually or simultaneously depending on shot requirements and machine configuration," he adds. These bigger LSR machines potentially could be used for other jobs, such as large static seals now made from HCR.

Machine developments

Apart from specialized applications, there is also a new crop of machines for general-purpose LSR jobs. Some new entries come from vendors that have not previously been active in this market. Milacron, for example, recently rolled out its first line of LIM machines up to 330 tons. They are based on a variety of machine platforms

Krauss-Maffei has also entered the LIM market with machines based on its C-Series, starting at 33 tons.

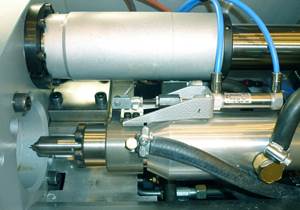

Arburg recently enhanced its extensive line of LSR machines, which are based on Allrounder S and Jubilee C models. All the LIM-related controls have been integrated into the main machine controller. Chief among the enhancements is a new mixing unit for small parts, which debuted at the K'98 show. According to chief engineer John Adamowitz, this integrated mixing and dosing unit employs servo-driven gear pumps to provide very precise positive displacement of the LSR components. Designed for small parts, the new unit has a shot capacity of 1 liter per component.

Many more injection machine suppliers than those mentioned here can and do supply LIM systems. Virtually any make of machine can be outfitted for LIM, provided it has a thermoset injection unit and a pumping system to deliver the LSR material from drums or pails. Pumping systems are supplied by firms such as Fluid Automation and RJS Precision Products.

Tool time

LSR tools may look like a standard injection mold, but they differ in many subtle ways, such as draft requirements, parts-removal methods, shrinkage, and tool wear, to name just a few. What's more, LSR flashes so easily

For these reasons, LSR experts cite experience as a key factor in building a tool for this tricky liquid. Scarcity of that experience was one of the main barriers to LSR's growth in the past, according to GE's Gensler. The industry's reservoir of LIM toolmaking competence has gradually expanded in recent years. An important tooling breakthrough for LIM is improved cold-runner systems over the last few years. A hot-runner system in reverse, these systems use manifold cooling to keep LSR from curing in the runner system between shots. "They can save anywhere from 5% to 60% of material cost, depending on the size of the part in relation to the runner system," explains Tony Brusca, president of ALBA Enterprises, which sells a cold-runner system made by EOC in Germany.

Cold runners have also liberated LIM from previous limitation on productivity. "Historically, LSR tools tended to be 32 cavities at the most," says Dow Corning's Johnson. He explains that tools with more cavities tended to experience filling problems because of premature curing. But with today's cold-runner systems, cavitation is on the rise. "You're starting to see tools with as many as 128 cavities," says Johnson.

A couple of LIM cold-runner systems are commercially available to toolmakers and have become well-established in North America. One is the EOC system from ALBA. It recently has been expanded from a maximum of 16 drops to 32, and custom sizes are also new.

In addition, Kipe Mold now offers two types of cold-runner systems, both for the company's own tools and as manifold systems that are sold separately to other toolmakers. One type is a valve-gate design that uses a reciprocating pin to create a single shut-off point. According to Kipe, this pin normally is seated flush with the nozzle tip to virtually eliminate any gate vestige on the part. In some applications, the pin actually extends into the part cavity

More recently, Kipe introduced an open-channel cold-runner system that lacks the reciprocating pins. Kipe calls this simpler design an "economical solution when a pristine shut-off is not necessary." Next month, Kipe will introduce its latest open-channel tips, nozzles, and manifolds, which can accommodate up to 200 drops. Kipe says they will cost 30-50% less than valve-gate systems.

Related Content

Datwyler Expands O-Ring Production

The company has added injection molding machines to production sites in Mexico and China to boost production.

Read MoreLSR Machine and Injection Unit Designed for Low-Shot Volumes

BOY will present its XS machine running an LSR application created in collaboration with the University of Kassel at DKT 2022 (June 27-30; Nuremberg, Germany).

Read MoreMinnesota Rubber and Plastics Opens Innovation Center

The plastics and rubber compounder and molder has opened the 9000-ft2 center that’s intended to help speed product development with design, prototyping, testing and production capabilities.

Read MoreBeacon MedTech Solutions Names New President

The Massachusetts-based medical molder and contract manufacturer has appointed industry veteran Jim Colony.

Read MoreRead Next

How Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read More