Materials: Algae to Replace Starch In Bio-Hybrid Compounds

In the continuing search for renewable raw materials to replace petroleum feedstocks in plastics, the newest candidate is … seaweed.

In the continuing search for renewable raw materials to replace petroleum feedstocks in plastics, the newest candidate is … seaweed.

By the end of this year or early in 2011, Cereplast, Inc. in El Segundo, Calif. plans to commercialize grades of its Hybrid compounds utilizing marine algae biomass—in other words, dried seaweed. Cereplast currently offers two grades of Hybrid compounds—part of its Sustainables family—consisting of conventional polypropylene blended with 50% to 55% starch from corn, tapioca, wheat, and/or potatoes. Cereplast aims to replace up to 30% of the starch with dried and powdered algae. Company CEO, founder, and chairman Frederic Scheer expects algae biomass to be a “drop-in” replacement for starch in terms of material properties—and he hopes it will prove to be less expensive in the long run. In addition, it will offer the ability to substitute what would be waste biomass for starch from food crops.

Cereplast gets its dried, pressed raw material from pioneering companies that process algae into biofuel. These companies grow the algae in ponds. After pressing out the oil, the remaining biomass is shipped to Cereplast. Until this year, the startup biofuel operations could provide relatively small amounts of algae. Scaled-up biofuel producers will be able to provide enough algae for 1 million to 5 million lb of Hybrid compounds in 2011, Scheer predicts. He also sees potential in the next five to 10 years to develop bio-monomers from algae oil or biomass.

BIG GROWTH SEEN FOR BIOPLASTICS

Scheer says 2010 will see a 400% increase in shipments of all of its bio-based plastics—both Hybrid and Compostable types—over 2009, achieving a volume of 16 million lb. The company’s new compounding plant in Seymour, Ind., can produce up to 80 million lb/yr of bioplastics at full capacity. Cereplast also recently signed global distribution agreements with Ashland Distribution, Columbus, Ohio (ashland.com), and with Bunge Alimentaris in Brazil.

Cereplast scored two notable new applications for its 100%-biodegradable Compostable resins this year. These resins, now available in 11 grades, consist primarily of polylactic acid (PLA) biopolymer from Natureworks LLC (natureworksllc.com), Minnetonka, Minn., blended with various amounts of other biopolymer or renewable resources such as starch. Most recent is the announcement that starting next month, Cereplast will ship 220,000 to 330,000 lb a month of its Compostable 7003 material to Sezersan Ambalaj in Turkey for production twist-wrap films for a variety of food products to be distributed throughout Europe. The new bio twist film reportedly has good deadfold behavior, is heat-sealable, and is thinner than other twist films. It is opaque or translucent.

And just this past summer, S.R. Promocionais Ltda in Brazil announced it will produce Eko BIO ballpoint pens, about 93% of whose weight will be injection molded of Cereplast Compostable 1001 compound. Scheer says, “It is estimated that the 10 billion ink pens thrown away each year will take up to 400 years to break down in a landfill.” This is the second biodegradable pen to be introduced this year. As we reported in June, Newell Rubbermaid Inc., Atlanta, introduced Paper Mate Biodegradable pens and mechanical pencils made mostly of Mirel PHA bioplastic from Telles, Lowell, Mass. (mirelplastics.com).

Related Content

Honda Now Exploring UBQ’s Biobased Material Made from Unsorted Household Waste

UBQ is aiming to expand its reach for more sustainable automotive parts as well as non-automotive applications.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreMelt Flow Rate Testing–Part 1

Though often criticized, MFR is a very good gauge of the relative average molecular weight of the polymer. Since molecular weight (MW) is the driving force behind performance in polymers, it turns out to be a very useful number.

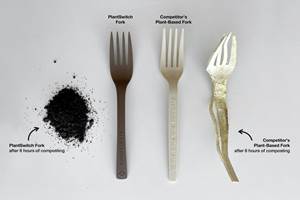

Read MoreAdvanced Biobased Materials Company PlantSwitch Gets Support for Commercialization

With participation from venture investment firm NexPoint Capital, PlantSwitch closes it $8M bridge financing round.

Read MoreRead Next

How Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More

.png;maxWidth=300;quality=90)